Introduction

In the new age of Industry 4.0, using digital twins in making goods is a big leap. These smart, copy models of real systems are not just ideas. They are really changing how smart factories work, change, and get bigger. For those who lead in making goods, digital twins make things more efficient, help with smart fixes before breaks, give real-time tweaks, and aid in making good choices.

If you run a big set up with many steps, or look after many factories, the pay-offs of using digital twins in making goods are too key to ignore. Let’s see how this tech is building the future of how we make things, and why HexaCoder is at the top of this change.

Digital Twin Solutions in Manufacturing

A digital twin is a new, live digital view of a real item, set-up, or system. In making things, it could be from one tool to a whole area where things are made. The digital twin gets live info all the time from things that sense, IoT devices, and systems that control all set into the real twin.

This live link lets leaders in making things try out moves, test out cases, watch how well things work, and guess issues — all in a virtual space, without messing up real work.

HexaCoder, a top group helping with digital change, gives special digital twin making answers made for smart factories. They help groups build these smart copies with new tech like IoT, AI, 3D making, and cloud storing.

Digital Twin vs. Simulation: What’s Different?

It’s easy to mix up digital twins with normal tests. The big difference is in live info joining and two-way talk.

-

Tests are set models used to plan.

-

Digital twins are live, changing models that show the real item right now and can send back rules to real systems.

-

In smart factories, this means you’re not just watching how things go — you can make it better as you go.

Benefits of Digital Twin in Manufacturing

For leaders in new making, going digital is not just a fancy word — it’s a must-do plan. And using digital twins in making things has shown to be one of the top ways for this change. The pay-offs reach way past just seeing things; digital twins act like smart, live copies of your making space — able to try out, study, and make things better in live time.

As makers face more need to cut stop time, speed up new ideas, lower costs, and take up kinder ways to our earth, the payback of putting money in digital twins is getting more clear. Here’s a deeper look at the many upsides, and how HexaCoder helps making clients get the most of these gains.

1. Predictive Fixing

One of the first and clear pay-offs of a digital twin is moving fixes from after-the-fact to before-the-fact. By always watching things like shakes, heat, push, etc., digital twins can spot early signs of wearing out, guess likely breaks, and suggest steps to stop them.

HexaCoder makes this better with AI smart guessing ways that not only find odd things but also shift with changing making needs. The end? Less breaks, tools that last longer, planned MRO times, and way less sudden stop times — all adding up to a more lean, strong set-up.

2. Live Time Making Better

In hard making set-ups, even small drop-offs in the way things run can grow to big losses over time. Digital twins give a live time view of making moves, letting makers try tweaks — like changing tool speed, moving how work flows, or changing things around them — and see the effects right on.

HexaCoder's digital twins have active sim engines that let plant workers try changes in a fake setting before making them real. This live feedback loop makes ongoing betterment not only doable, but safe and based on data.

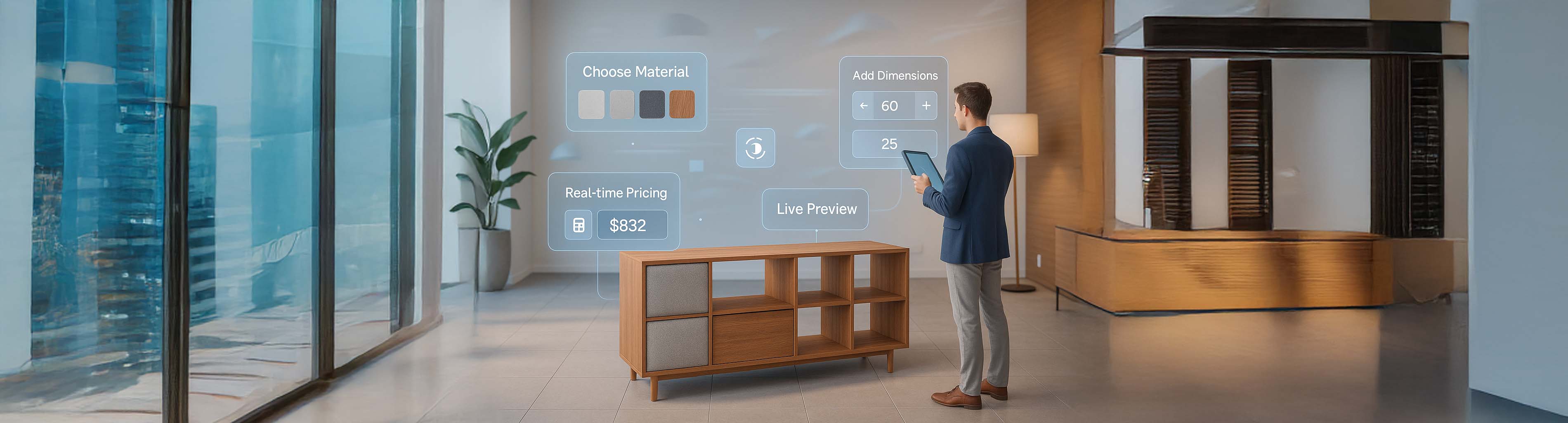

3.Better Product Design and Fake Building

Digital twins are not just for machines and systems — they are changing product making too. Makers can now make fake copies of new goods, test how they are used, try different stuff, and make changes fast — without making costly real models at each step.

HexaCoder aids R&D teams in developing 3D models attached to sensors showing how a product acts under pressure, heat, wear, and other harsh conditions. The whole process is then together--faster product innovations, early failure detections, and shortening the cycle from designing to marketing, all the while conserving R&D foundation.

4. Faster Time-to-Market

There is the ability to model the full making lines and steps and test them. Makers can find slow parts and correct them before further making. It eliminates trial and error most of the time, which goes with taking up a new product or method.

HexaCoder's digital twin tools back testing of making lines and digital setups so that the teams can simulate these steps. This greatly cuts down the time-to-market and cost of setting up new factories or product lines.

5. Remote Monitoring and High-Level Control

Today's manufacturing is often spread out over many sites in several countries. Digital twins let monitoring authorities oversee such remotely placed plants. From his plant to the director general, he gets a Live!

HexaCoder keeps safeguarded cloud panels, associated with live digital twins for remote monitoring, top-level control, and long-range planning-primarily when sudden sight: a stoppage like a supply chain issue or a natural calamity.

6. Use of Energy and Care for the Earth

With more focus on green matters, using energy well is key — it must be done for work. Digital twins can track energy use across tools, making lines, and sites, find weak spots and better use.

HexaCoder's green-focused twins work with meters for energy, water use sensors, and gas watch tools to give a live green score look. Makers can try green changes, watch carbon marks, and move toward zero waste goals — all backed by good data.

7. Quality Checks and Rules

Quality control in old making leans a lot on group tests and checks after making. Digital twins let for fake quality checks — testing stress, pull, wear, or heat on fake models to find quality issues before they show up.

HexaCoder boosts this with AI-driven fault finding and view check tools, into the digital twin model. This lets for live QA during making and makes sure work meets work rules and needs — key in jobs with tight rules like drug making, flying, and car making.

8. Job Training and False Rules

Digital twins might be the greatest training tool for operators and engineers alike. Instead of learning on real tools — which, of course, can be risky or expensive — new crew members can train in fake setups and learn how machines really work, job rules, and critical procedures.

HexaCoder sets up the learning scenario game and fake rule systems with the same twin used in jobs, ensuring consistent and repeated training that is safe.

9. Preparation of a Truly Working Supply Chain

Ordinarily, with the move toward Mixed Assembly Processes with dominant Twincrafts, the next step would be Multi-Company Digital Twins, where suppliers, sellers, and OEMs have a shared digital view of the making step. Early supply chain fixes, faster teamwork, just-in-time stock line-ups can, therefore, happen.

HexaCoder helps companies in integrating external tools and vendor data streams into digital twin solutions to achieve effectively functioning supply chains, which are highly important in jobs that involve extended delays or that concern fast spoilage.

10. Smart Plan Making and Being Strong

Among the best forward-looking advantages of a digital twin is the ability to try out what-if scenarios: for example, supply stops, not enough workers, and sudden spike demands. Test backup plans in the fake environment so that the manufacturers may build a strong work-life environment online.

HexaCoder empowers teams to embed custom planning tools into their digital twin setups to enable managers in making smart risk-conscious decisions

Real-World Applications: Digital Twin Manufacturing Operations

Smart Assembly Lines: Create digital twins for all of the steps in a complex assembly line, covering everything from human stations to robotic arms. By keeping real-time track of throughput, cycle times, and process deviations, inefficiency or misalignment get immediate flags to enable proactive corrections.

Energy Optimization: With HexaCoder's twins modeling live energy flows and machinery states, the factories realize reductions in the consumption of electricity, avoid peak loads, and permit the smart planning with which to use energy. Over time, this results in smaller utility bills support bigger sustainability goals.

Quality Testing & Assurance: Contrary to the destruction of products by testing, virtual assurance has been introduced by digital twins, with regard to durability, lifecycle performance, or failure modes testing. This in itself saves large amounts of material waste, cycles of tests, and QA costs, especially in precision manufacturing.

How HexaCoder Constructs Production Digital Twin Solutions

Digital twins are not all the same. In an industry as complicated and fast-evolving as manufacturing, what will actually make digital twins valuable is not developing mere automated replication of physical systems but enabling manufacturers to execute simulation, prediction, and optimization in real time. For all that, they must have customization, scalability, and seamless integration, which may not be negotiable. That is exactly where HexaCoder stands out.

From Tier-1 suppliers to global OEMs, HexaCoder is helping the progressive manufacturers realize the complete potential of manufacturing digital twin applications-especially transforming isolated assets into intelligent, interconnected, and responsive systems.

Tailored Digital Twins for the Industry-Built to Fit, Not Force-Fit

One of the largely unnoticed challenges of digital twins is industry relevance. Manufacturing does not lend itself to a one-size-fits-all model. A model that works perfectly for a semiconductor fab might not be at all suitable for an FMCG production line.

HexaCoder truly knows this. That is the reason why their digital twin development begins with very thorough discovery workshops engaging plant managers, heads of operations, and industrial engineers. Whether it is an aerospace assembly line or a high-speed consumer goods bottling plant, their engineers get into the last details-the equipment, workflows, downtime pain points, data flow, and strategic KPIs associated with the business.

This makes it possible to customize the digital twin architecture so that it mirrors the true process-it adds measurable value.

A Full-Stack Digital Twin Platform: More Than Just a Mirror

What differentiates HexaCoder's from other digital twins is full-stack technology integration. Unlike most vendors who provide fragmentary solutions, HexaCoder gives an end-to-end platform consisting of: IoT sensors and edge devices to collect real-time data from shop floor Cloud-based data lakes for storage and scaling of digital twin models AI & machine learning engines for real-time analytics and predictive maintenance 3D visualization layers using WebGL or Unity to provide immersive, interactive factory twins APIs and data bridges for smooth integration with the existing systems such as ERP, MES, SCADA, and PLM.

Such a layering process makes the digital twin not just an eye-catching simulation but rather becomes a decision-making engine to be embedded into the digital nervous system of your factory.

Therefore, the plant head can simulate line changes before implementing them, while maintenance teams can predict failures weeks in advance, and executives can visualize KPIs in real time from the boardroom.

Scale, modular and long-term

An intelligent factory is not built overnight. Yet, most vendors seem to pursue full-scale, expensive, almost overwhelming digital twin projects. HexaCoder offers a more sustainable, modular approach. Begin with a pilot-a digital representation of a single machine, CNC line, or warehouse process. Validate the ROI. Scale to the rest of the line, department, or even plant.

This is a good approach by which HexaCoder is meant for those manufacturers willing to test and scale but without incurring high initial risks. Their systems are designed to be scalable, allowing for phased implementation across sites or countries while keeping centralized control.

Solving the Most Challenging Problems of Digital Twin Implementation

Digital twin has promised too much, but only if done well. It is understandable that many of the leaders in manufacturing often get stuck at the pilot stage due to real challenges, such as:

1. Low-Quality Data Poor data quality is a stumbling block for a digital twin. A digital twin can be called intelligent only if proper data is fed into it. HexaCoder applies stringent sensor calibration, employs robust data cleaning pipelines, and builds up an AI-driven detection system to ensure that the data remains accurate and trustworthy.

2. Legacy Compatibility Owing to parts of factories that still run on systems from past decades (like PLCs) along with proprietary ERP setups, HexaCoder can build custom middleware that connects these legacy systems to new digital twin layers-creating a seamless flow of information rather than any major rip-and-replace.

3. Financial Justification These are the "nice-to-have" toys that usually come at the high cost of a digital twin. HexaCoder, seeing the value in digital twins, has remolded these tools as ROI pieces. Their planning model focuses on ROI, which may further drive use cases with quick wins such as predictive maintenance or energy optimization, and gives manufacturers immediate savings in some months rather than years.

The Future of Digital Twins in Manufacturing: What's Ahead

We are moving farther with the naive digital twins, and beyond these are collaborative autonomous and sustainable twins that extend outside the factory gates.This is the world HexaCoder is already creating. Some of the areas in which they are developing include:

-

Self-healing systems powered by AI will detect and correct anomalies without any human intervention.

-

Collaborative twin networks connecting manufacturers to suppliers and logistics partners to create real-time, supply-chain-wide intelligence.

-

Edge twins for short-latency decision making in ultra-fast environments like Semiconductors or Automotive.

-

Green Twins designed to monitor and optimize energy use and emissions and minimize waste to help factories realize global ESG goals.

Such best-in-class capabilities will play a crucial role in ushering industries into the net-zero regime and circularity in manufacturing.

Why HexaCoder? Definitely more than a tech vendor

While many companies sell "digital twin" software, few blend deep manufacturing know-how with fighting tech execution. And this is where the difference lies with HexaCoder.

With a core team of data scientists, mechanical engineers, IoT specialists, and manufacturing consultants, HexaCoder does not just deploy tech; it builds operational intelligence.

The experience spans projects across:

-

Automotive component factories with aspirations to reduce downtime

-

Electronics manufacturers interested in batch-level traceability

-

Aerospace companies simulating real-time system assembly

-

FMCG plants minimizing water and energy through green twins

In any industry, HexaCoder comes with a singular focus: to build digital twins that deliver business value from Day 1.

Conclusion: Are You Ready to Build Your Factory's Digital Twin?

The advantages of digital twins in manufacturing are no longer theoretical. They exist — and are changing factories from the ground up, across energy efficiency, real-time visibility, predictive insight, and sustainability tracking.

But digital twins are no plug-and-play solution. The partner for this class of project must understand both industrial complexity and digital agility. This is HexaCoder's standing forte.

Be it piloting your first digital twin project or going full tilt to digitize your entire manufacturing ecosystem, HexaCoder will help you build scalable intelligent systems that are tailor-fit to your every requirement.

Want to Digitally Twin-Proof Your Factory or run manufacturing operations? Visit HexaCoder.com, or book a free consultation with their team on industrial transformation today.