Digital Twin Solutions for the Oil and Gas Industry.

Cut downtime. Boost Safety. Maximize Output.

0%

Conversion lift

Real-time insights, predictive maintenance, and drilling optimization—payback in weeks.

Business Approaches

Discovery & Strategy

Our process starts with evaluating your systems, workflows, and assets. From defining set production goals and operational gaps, we align outcomes with strategy. Each digital twin is programmed for today’s challenges while ensuring scalability for future demands.

Custom Development

We create bespoke scalable digital twins for your operation using modular structures and sophisticated 3D frameworks. Each bespoke solution meets the standards of precision, ergonomics, and efficiency. This enables and streamlines process monitoring, simulation, and optimization - all of which can be performed with minimal training prerequisites, and greatly reduced errors.

Seamless Integration

Your digital twin seamlessly integrates with SCADA, ERP, and other cloud systems. This enables real-time information synchronization across departments, automation of workflows, and positions the twin as the operational efficiency, risk mitigation, and decision-making nexus for the value chain.

Testing & Optimization

We perform extensive validation of every deployment for performance, accuracy, and usability alongside other metrics. During this process, we detect bottlenecks and refine models to ensure digital twins perform consistently across rigs, refineries, and pipelines at an enterprise scale.

Ongoing Support

We provide continuing training, upgrades, and scaling support. As your operation grows, we stay engaged even after post deployment.

Our Core Offerings

For enhanced operational effectiveness, safety, and scalability within the Oil and Gas sector, we offer tailored digital twin solutions. From upstream exploration to downstream operations, we assist you with modeling, monitoring, and maximizing value from each stage of your business.

Platform Features that Matter

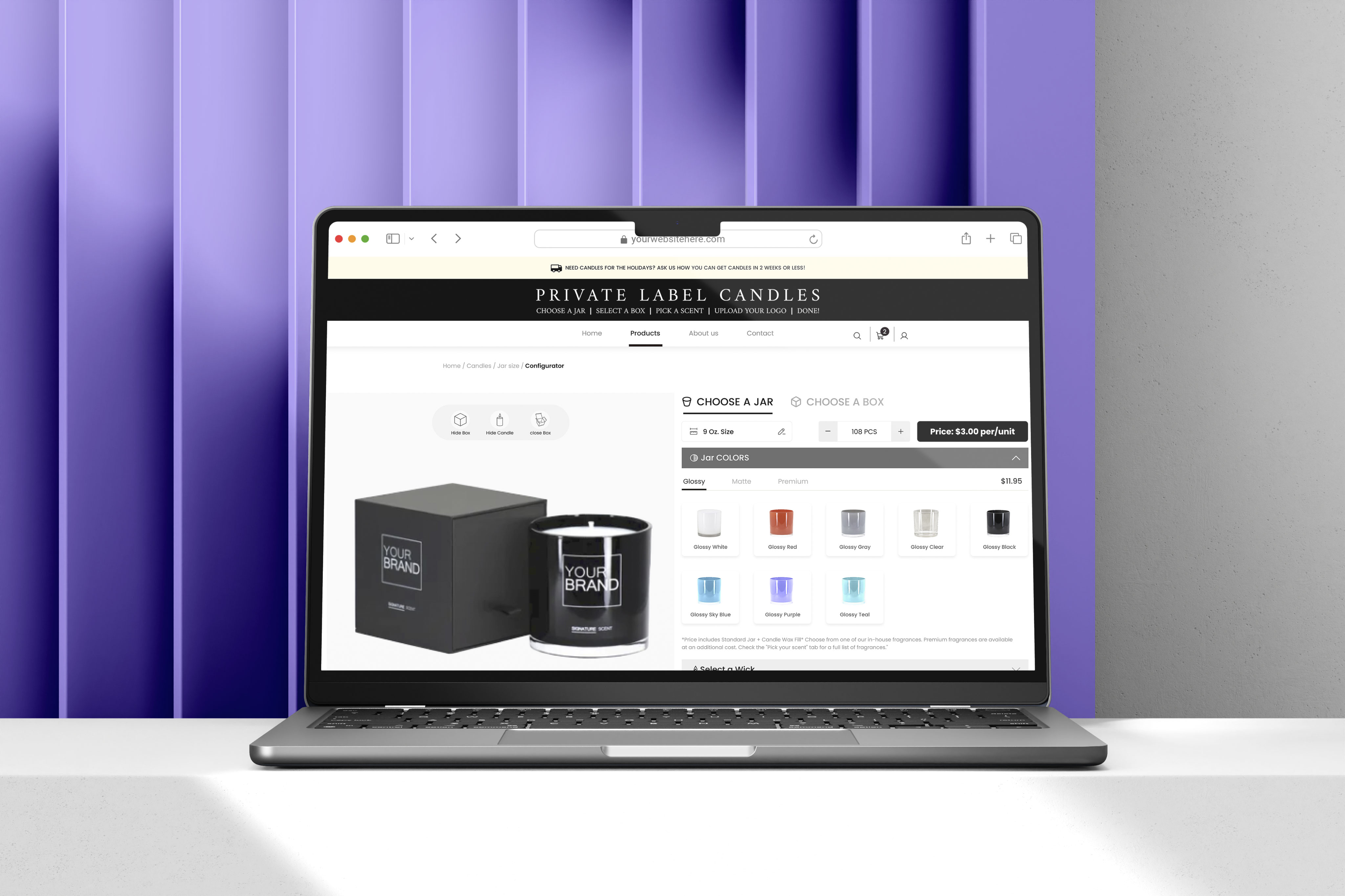

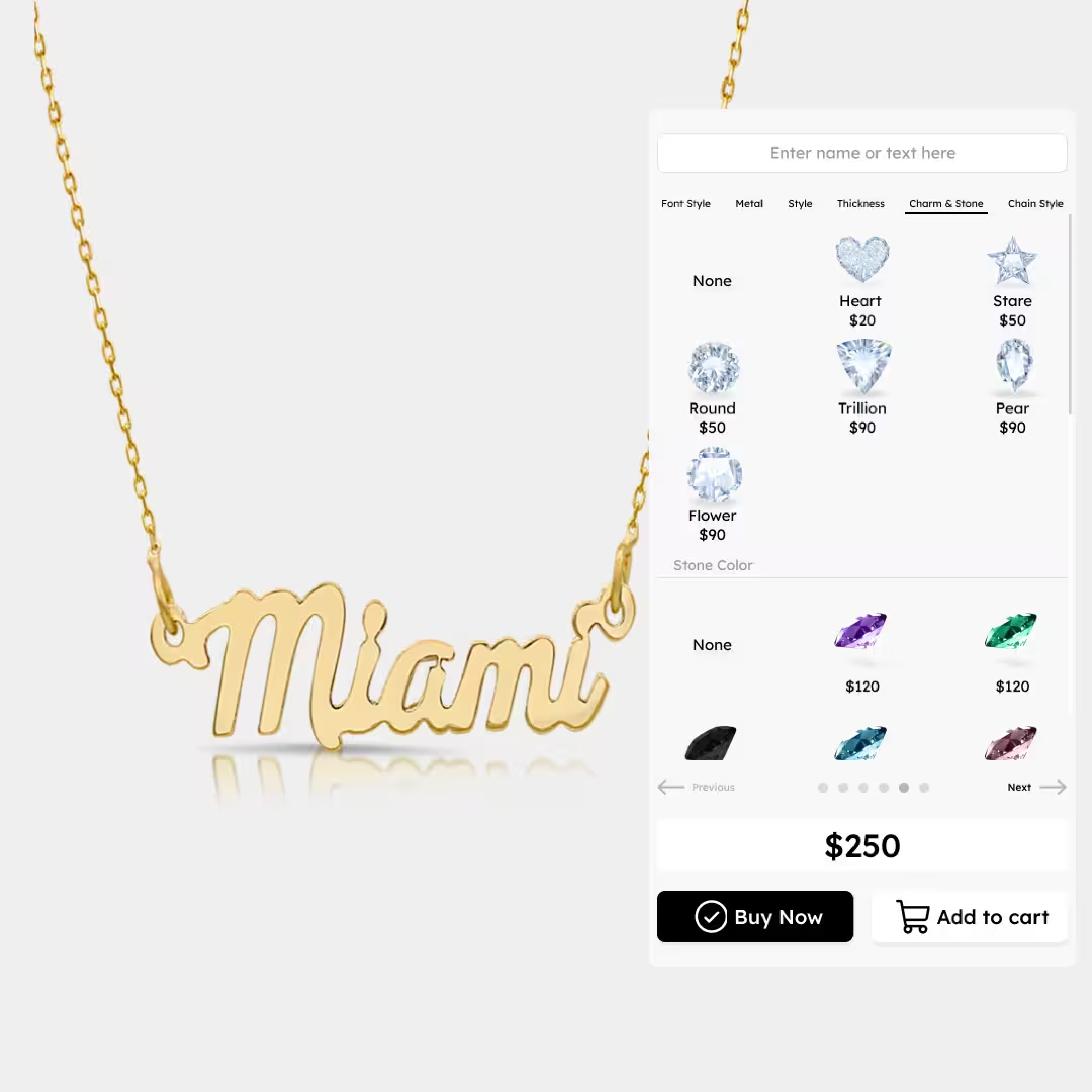

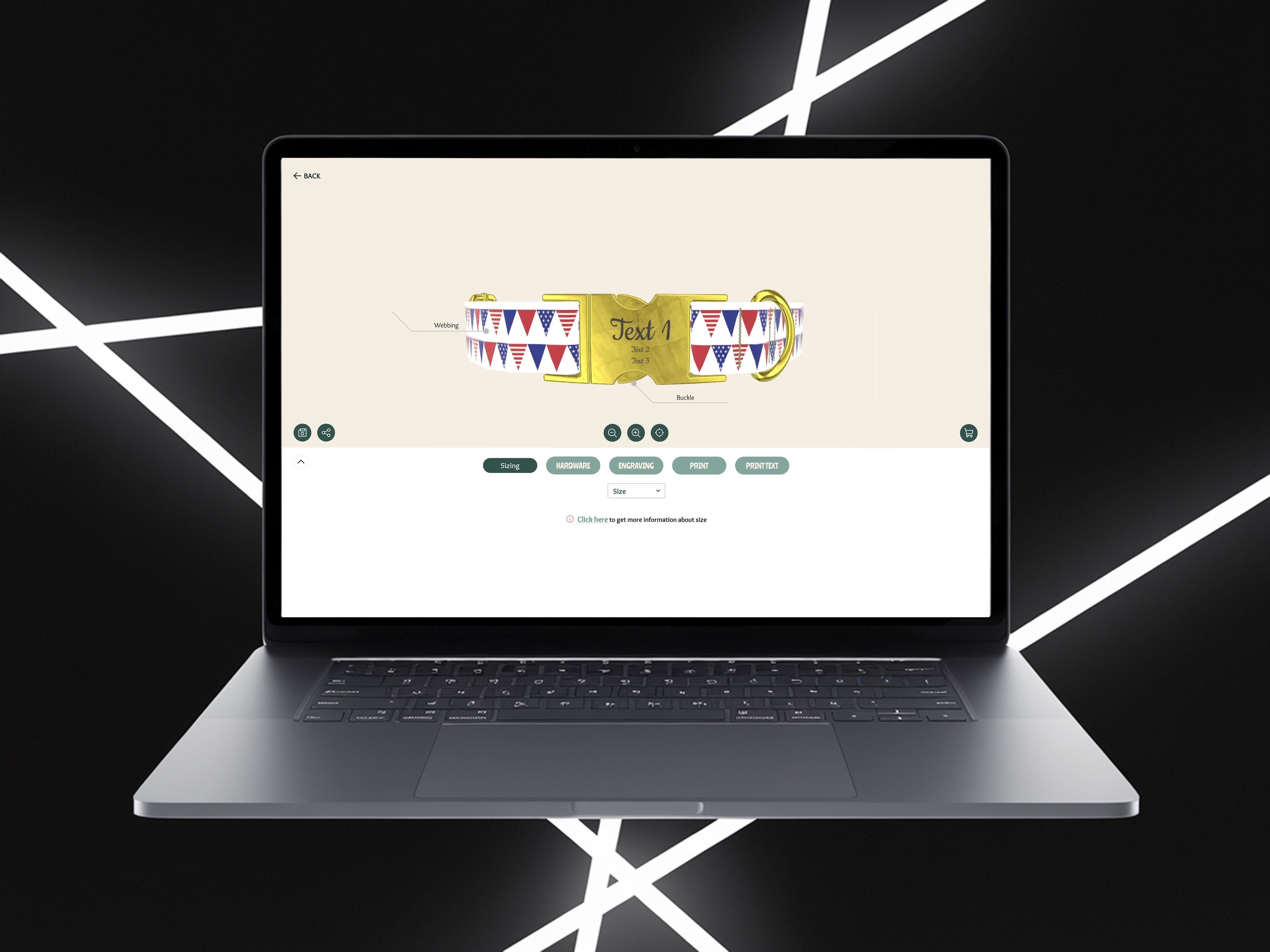

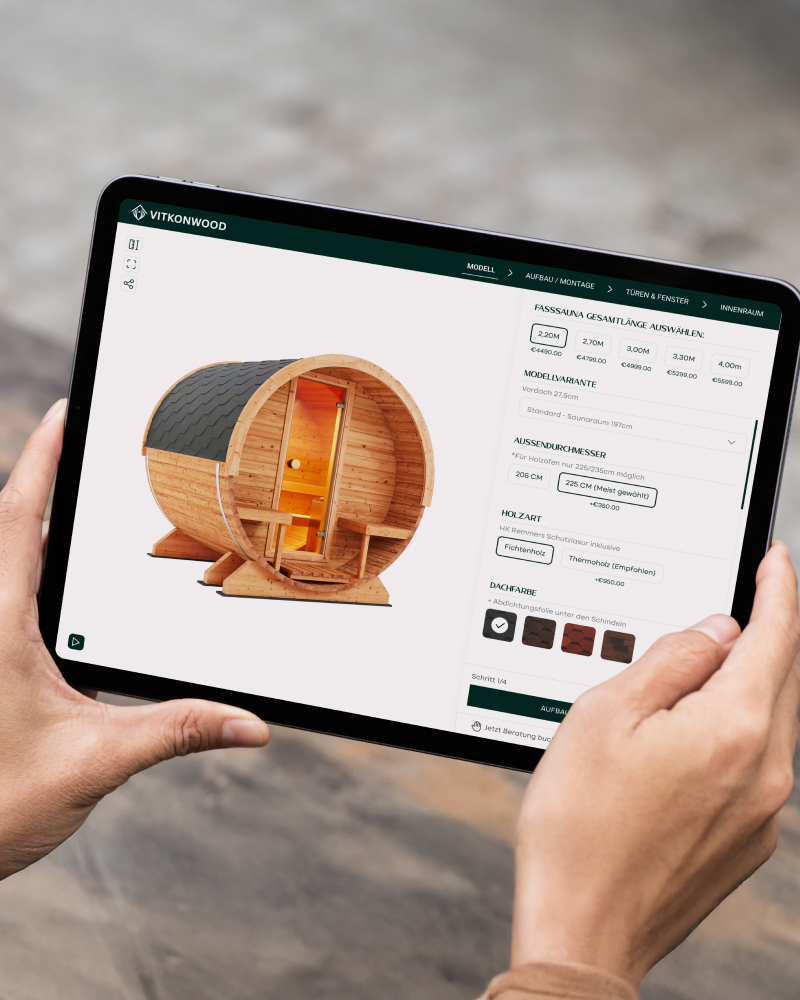

Our Expertise in 3D Configurator Development

Visualization of Assets in 3D with Full Interactivity

Utilizing high-precision rendering techniques, look at rigs, pipelines and refineries in fully immersive 3D. 3D visualization helps in planning without ambiguity, accelerating iterative design, reducing operational errors and accelerating approvals. Moreover, enhanced visualization not only assists engineers in understanding critical project infrastructure but also transforms project cycles and assists in better enterprise-wide decisions driven by the need for safety.

Rule-Based Operations Customization for Workflows

Integrated smart rules within every digital twin facilitate the automation of intricate operational workflows. From drilling parameters, and refinery throughput, to safety constraints, our system adjustment capabilities cater to the specific needs of every site. This assists organizations in staying compliant, reducing rework, and increasing pace in processes, transforming sluggish, erroneous procedures into reliable digital workflows that foster growth.

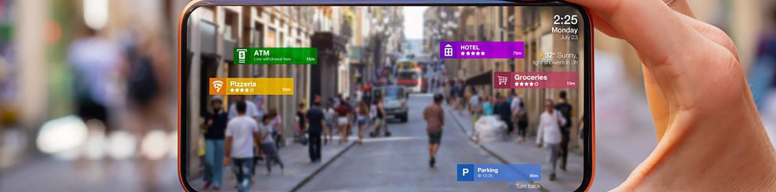

Integrated System without Boundaries

Link your digital twin with ERP, SCADA, IoT and cloud systems for integrated operation without boundaries. This promotes cross departmental real-time data sharing, breaks silos, and enhances cross-discipline collaboration between engineers, operators, and managers.

Advance Energy Operations with Custom 3D Twin Services

Integrated digital twin solutions for the oil and gas industry emphasize effectiveness, safety, and the ability to scale. We assist you in modeling, monitoring, and maximizing every stage of your business from upstream exploration to downstream operations.

Our Available Solutions

Startup Solutions

For new operators and energy startups venturing into the digital twin domain, the cost estimator offers invaluable insight. It ensures that early-stage infrastructure planning and resource allocation are strategic, scales without overspending on 3D simulation technologies, and ensures overspending on 3D simulation technologies.

Business Solutions

Growing energy companies stand to gain from our project estimators to aid in budget management interfacing digital twin technologies. This provides predictable software expenses, seamless integration with control systems, and cost-efficient scaling from regional to multi-site operations.

Enterprise Solutions

Large enterprises gain from our comprehensive cost analysis by having tailored insights into intricate multi-asset projects. This allows optimized allocation of constrained resources, comprehensive real-time monitoring of systems, and controlled spending of implementation during cross-section monitoring of exploration, production, refining, and distribution departments.

Transform oil and gas operations with boldness

Don't just monitor, predict prevent and perform at the highest standard. Our enterprise ready Digital Twins platform is designed for scale and built for today oil and gas realities

Travel and Hospitality

Revolutionizing travel with immersive 3D and digital twin technologies for better experiences and operational efficiency.

Explore Our Portfolio

Why Choose HexaCoder?

Choose HexaCoder for oil, gas, and mining because we provide advanced digital twin solutions that enable real-time monitoring, predictive maintenance, and operational optimization specific to these industries.

Cutting-Edge Technologies for 3D Configurator Development

We leverage the latest technologies to deliver exceptional 3D configurator solutions.

Real Results. Real Client Impact.

Your Industry, Our Tailored Solutions

We stay closely connected to evolving business trends and market developments, helping you anticipate change, make informed decisions, and position your organization as a leader in your industry.