Empowering Industries with Next-Generation Industry 4.0 Technologies

Boost Your Industry 4.0 Efficiency

0%

Conversion lift

Integrate our digital twin solutions to boost performance and increase conversions with real-time insights and predictive analytics.

Business Approaches

Discovery & Strategy

Start by studying the plant’s work routines, machine paths, and output goals, then build from the start to find weak spots. Mark them as set action items that are measurable and link directly to lasting factory targets. Confirm the system not only solves today’s process limits, but also sets plants with a course required for future progress.

Custom Development

With advanced plant design tools, we create flexible and adaptive digital setups. Each program balances detail and speed which lets staff quickly test layouts and improve assets, reduce faults and smooth tasks across the work floor.

Seamless Integration

Linked systems and tools close the gap between your twin models and other factory setups, device webs and business systems. This delivers site control that grows into a self-reliant and lasting base that preserves results and trust.

Testing & Optimization

Through steady checks, every rollout is tested for precision and strength. Interfaces are built to make sure that your plant’s twin works with certainty and speed across varied systems and setups.

Ongoing Support

Our part is not limited to the first launch. We provide help, updates and scaling support as plant needs shift. Your twin moves with your site, with steady upgrades, tighter safety and new options that fit changing rules and goals.

Digital Twin Solutions Driving Industry 4.0 Transformation

Boost advancement in industrial operations with modern industry 4.0 digital twin services. Gain full clarity, refine process efficiency and secure informed decisions to reach higher productivity, dependability, and sustainability in every workflow.

Platform Features that Matter

Our Expertise in Industry 4.0 Digital Twin Solutions

Real Power System Visualization

We provide clear, detailed, and interactive representations of machines, production lines, and supply points for managers and engineers using digital twin technology. Accurate modeling removes uncertainty, allows rapid testing of various scenarios, reduces costly planning errors, and shortens project timelines. This enables manufacturers to make decisions that are both timely and backed by solid evidence.

Custom Rules & Workflows

Our digital twin solutions use practical rules to manage scheduling, resource allocation, and safety requirements. Tailored workflows help teams maintain compliance, cut down on mistakes, and speed up decision-making. Tasks that once required repeated manual effort and complex calculations are now executed smoothly, efficiently, and dependably.

Smooth Energy System Integration

Integrating a digital twin into existing energy systems ensures seamless connectivity, real-time data exchange, and uninterrupted operations. By bridging traditional infrastructure with advanced virtual models, businesses can monitor performance, predict failures, and optimize efficiency without disrupting ongoing processes.

Digital Twin Experience

Elevate factory production and infrastructure management with tailored digital twin manufacturing platforms powered by real-world modeling and interactive simulation tools.

Our Available Solutions

Startup Solutions

For startups focused on industry 4.0 digital twin manufacturing, our cost estimation tool gives practical advice to plan finances wisely and allocate resources effectively.

Business Solutions

For growing factories, our affordably priced, detailed project estimates help manage budgets while expanding digital twin manufacturing capabilities. This ensures cost-efficient growth, predictable system investments, and well-organized workflows across production lines.

Enterprise Solutions

Comprehensive analysis for large manufacturers and corporations, combined with our client-centered approach, provides practical insights on extensive factory projects. This helps optimize resources, manage deployment costs, and maintain smooth operations across multiple units.

Industry 4.0 Digital Twin Power

Transform manufacturing processes with intelligent digital twin solutions. Talk to our expert today.

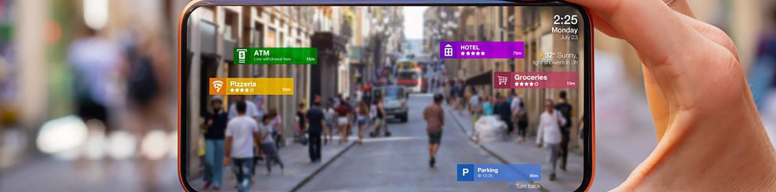

Travel and Hospitality

Revolutionizing travel with immersive 3D and digital twin technologies for better experiences and operational efficiency.

Explore Our Portfolio

Hexacoder – Your Ideal Industry 4.0 Digital Twin Software Partner

We don’t just create standard digital twin solutions that many industrial companies use; we also develop applications and use cases the sector hasn’t encountered before. Our skilled team of developers enjoys tackling challenges, finding new digital twin opportunities that help clients achieve operational efficiency and meet strategic goals

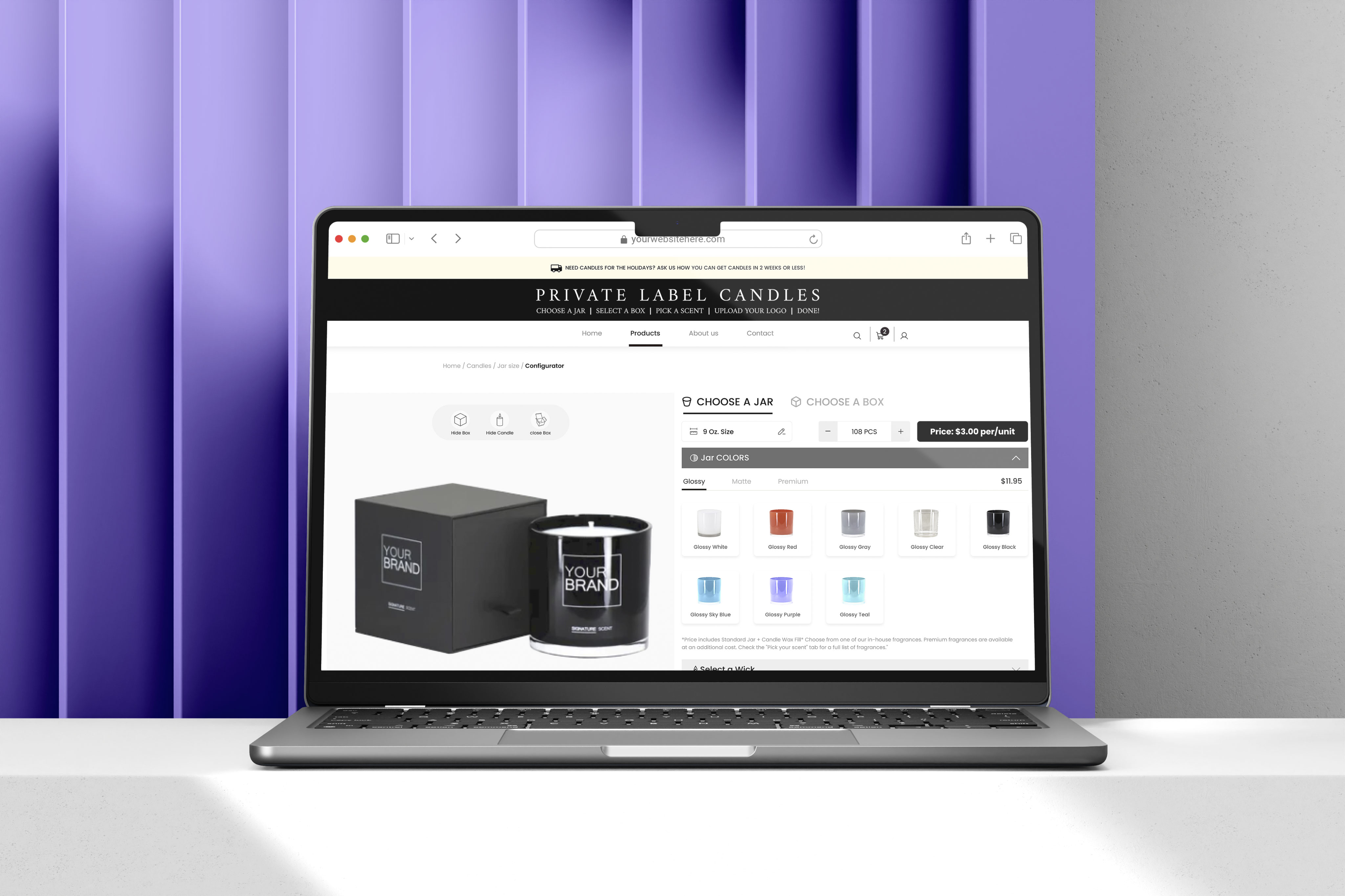

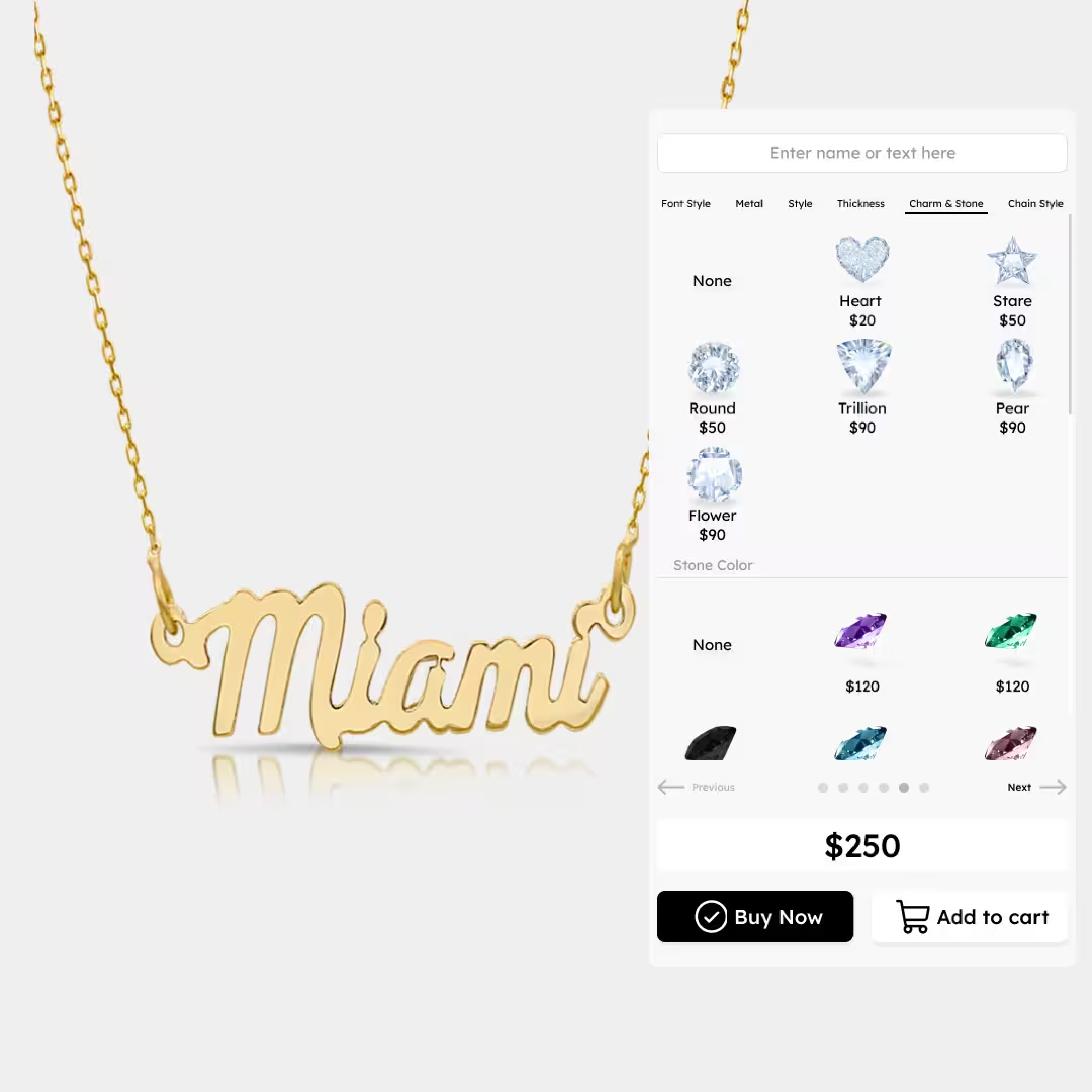

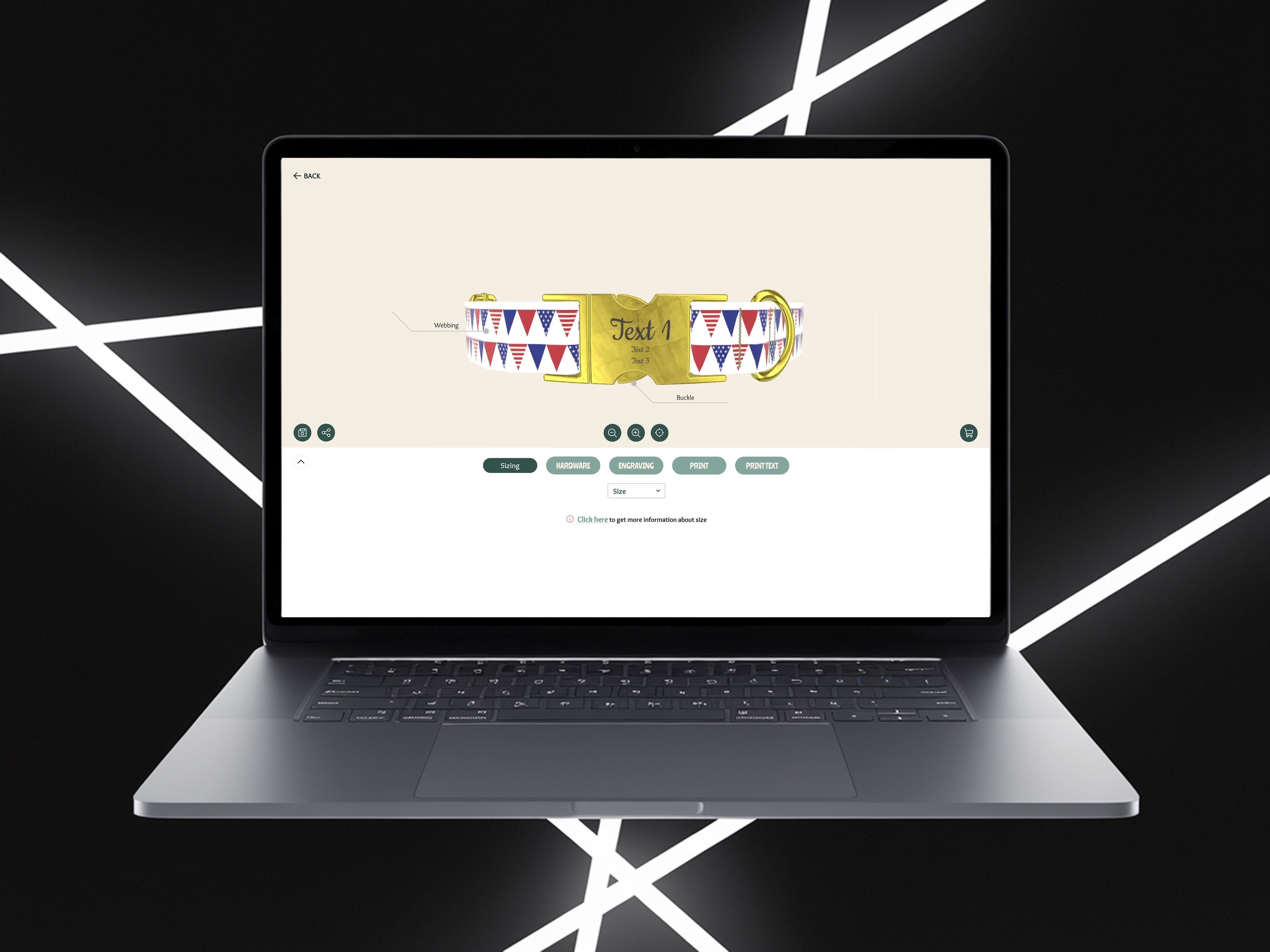

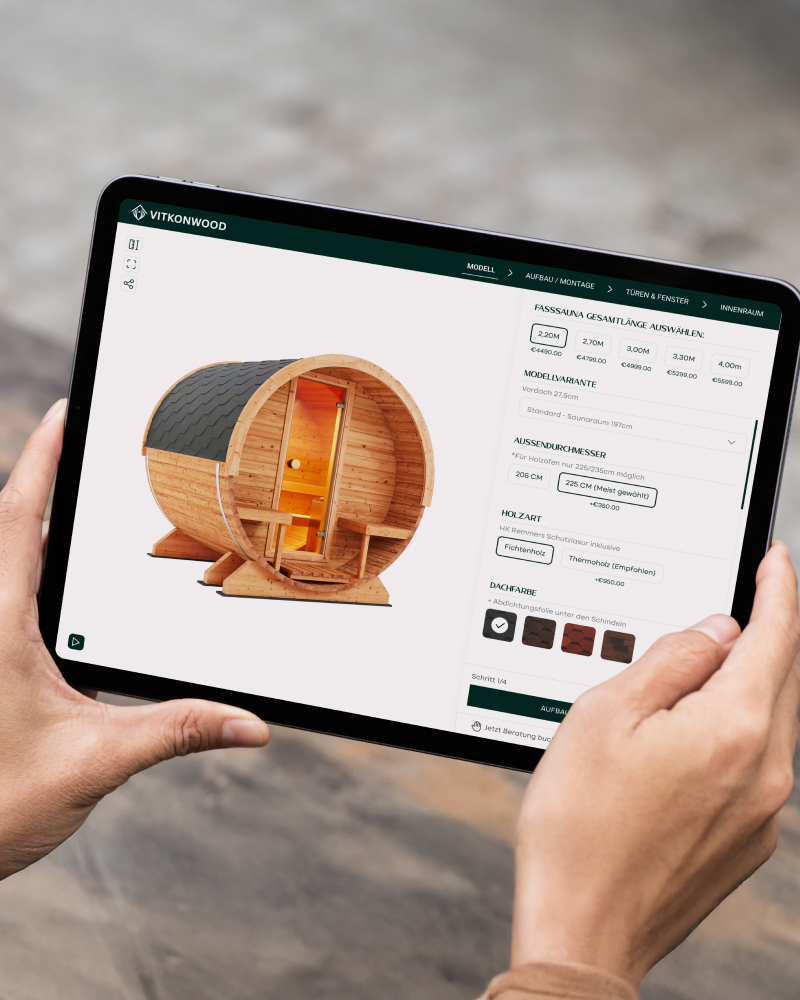

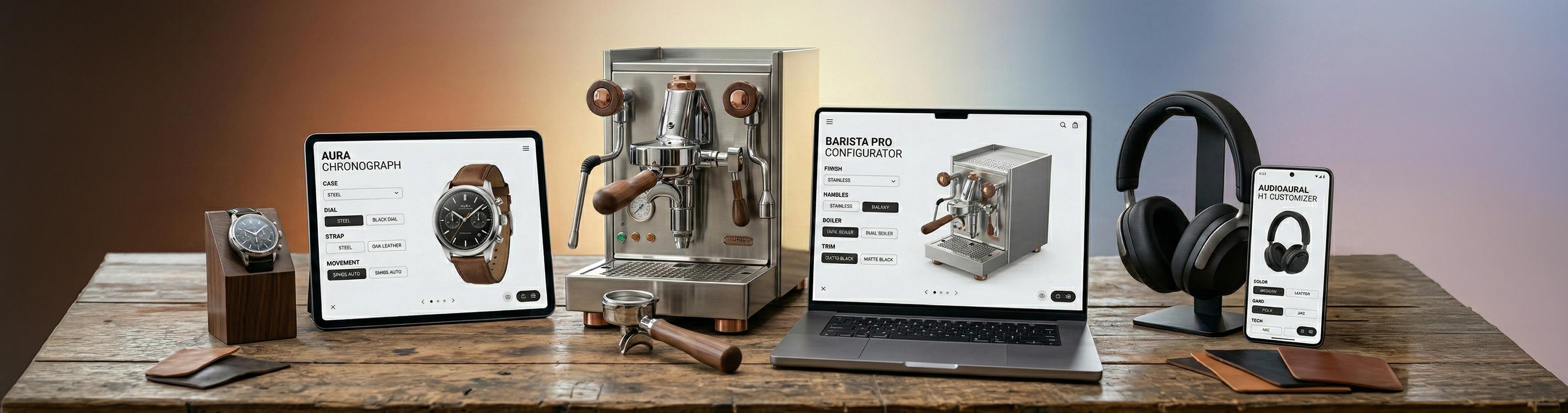

Cutting-Edge Technologies for 3D Configurator Development

We leverage the latest technologies to deliver exceptional 3D configurator solutions.

Real Results. Real Client Impact.

Your Industry, Our Tailored Solutions

We stay closely connected to evolving business trends and market developments, helping you anticipate change, make informed decisions, and position your organization as a leader in your industry.