The process of digital change goes beyond shifting data to the cloud and implementing new software tools and solutions into the organization. Organizations today embark on implementing digital solutions within their systems only to end up struggling with understanding their products, processes, and operations as a whole. Information may exist within the organization; however, the challenge comes with this information being fragmented and not easily interpretable.

This is where the digital twin becomes critical. Basically, the digital twin is basically the virtual replica of any real-life object or product. Essentially, it showcases how that object looks and how it has been designed and how it works. Unlike models that would just sit still and remain static, the digital twin would change from time to time depending on the various aspects that come into play.

The Rise in Demand for Digital Twins

Digital twins were considered cutting-edge technology only for big companies in aerospace,automotive, orindustrial sectors. Now, even in those sectors, there is a requirement beyond what was considered normal in the past. With increasingly complex products, variations, and options, along with increasingly integrated supply chains, there is a critical need to understand interactions between different components.

Without a digital twin, companies are operating on scattered data, guesses, and outdated models. This means that errors can be overlooked until further down the line in production, delivery, and finally use. Teams spend time and energy trying to fix problems, as opposed to innovating and trying to change and adapt and predict what might be needed tomorrow and beyond."

This makes it possible to view the entire scenario prior to action through a digital twin that provides a “single place of truth” reference. The digital twin has proved particularly useful in industrial equipment, electronics, autos, high-tech manufacturing domains. However, it is also being increasingly used in the service sectors as well as retail stores with complicated product lines.

Better Decisions, Faster

A digital twin offers one of the most direct benefits of better decision making. A digital twin will allow teams to make decisions not based on assumptions, but based on facts. For instance:

Engineers are also able to simulate the design and look for areas of conflict before creating prototypes. The operational staff will be able to monitor the performance and maintenance requirements of equipment even before there is a mechanical failure.

Product managers and executives can now make the right decisions regarding feature addition, price changes, and production plans after having a clear view. When every single business choice relies upon accurate and verifiable information, the potential for mistakes and misunderstandings will decrease. The time spent working to resolve these issues will decrease as well since teams will not be reacting to fires and will be able to become proactive and take initiative to implement strategic plans.

Teaming and Collaboration Across Teams

Digital Twins can also facilitate collaboration. All engineering, production, operation, and management staff share the same model. This helps because they are literally “on the same page.”

Rather than using emails, meetings, or static diagrams, teams can use the digital twin for discussing design variations, improvement suggestions, or customer inputs. Misunderstandings can be eliminated. Faster decision-making becomes possible.

A digital twin can also be used for training purposes. New staff can navigate through the system and learn about different components without posing any kind of danger or disruption to existing resources.

Reducing Risk and Cost

There are practical monetary advantages to the implementation of a digital twin. Errors identified at a later stage of production or when in operation can often cost a lot. This approach to simulation allows for the avoidance of costly stops and optimization of the production schedule.

For instance, a company that deals with the manufacture of heavy industries can use modeling to create a new configuration for a machine. In this case, the manufacturer will be able to create a new model for a machine even before the construction process begins.

Digital twins also simplify the issue of compliance and reporting. Wherever the regulations require evidence of design and test activity and subsequent performance the digital twin offers the ability to very easily obtain information on how something was designed and tested.

Enabling Customer Engagement

In addition to internal advantages, the use of digital twins is increasing for the purpose of customer experience enhancement. Sales representatives are able to demonstrate live and interactive prototypes of the product to customers. Customers are then able to navigate different configurations and the functionality of the respective product before they buy.

This openness helps build trust and prevents any kind of misunderstanding between the two parties, resulting in a quick close on a deal,a huge benefit when you think about industries such as production, real estate, and equipment where what you are offering has to be exactly what people want.

Developing Your Digital Twin Strategy

A digital twin cannot be created overnight. It needs planning and the right set of tools. Here are some ways to do it:

- Specify Objectives:

Identify what you want to accomplish using the digital twin. Do you want to use it for product development, for operating analysis, for sales representation, or for all of these? Having objectives will make it easier to select the technologies that should be used.

- Key Stakeholders Should Be Identified:

The list of key stakeholders that should be involved in the planning phase includes engineering, production, information technology, and sales. Every group of stakeholders tends to have its requirements and, therefore, the solution should meet those requirements.

- Start Small, Scale Gradually

- Pilot for a product or a process, test the models, and then implement the strategy for the entire organization.

- Data Accuracy:

The digital twin will only be as accurate as the information that it is based on. One must spend the time necessary to confirm information. Maintain the digital twin with up-to-date information as information occurs.

- Integration With Existing Systems:

Connect your digital twin to your existing ERP and operational systems. It helps automate the flow of data.

- Plan for Maintenance and Updates:

Every product, system, and process will change and develop over time. The digital twin needs to be kept up to date so that it can remain accurate and useful.

Digital Twin Success Stories

The organizations that effectively implement digital twins observe certain benefits of digitalization:

- Smaller development timeframes:

Virtual testing and validation mean fewer prototypes are needed.

Predictive maintenance maximizes operational efficiency with proactive maintenance.

- Reduced production defects:

The simulation and testing done in the digital twin identifies design and configuration faults early.

- Enhanced customer confidence:

Customers get a chance to investigate and validate configurations before any production takes place.

Even small successes add up. A nicely maintained digital twin provides a prime reference point for design, manufacturing, and operation. It serves as the foundation for continuous improvement and overall efficiency.

Timing Is Critical

The tempo of business is presently more rapid than at any point in the past, and costs of delay are high. Enterprises that delay embracing the concept of a digital twin continue to function using outdated processes, fragmented data, and decisions made through guessing. Such an approach tends to result in errors that could have been avoided, slowing down an enterprise and allowing time and resources to go to waste. A small mistake could easily result in high costs.

A lack of, or inadequate, view on products and systems within a given group often leads to a greater amount of time being devoted to fixing problems as opposed to developing new value streams. Reaction and response are enacted as opposed to engaging in proactive approaches and decisions, and valuable gains are lost due to a lack of clarity and consistency within available data for informed decisions.

The implementation of the digital twin today provides the key benefit of being able to quickly and accurately model and analyze any product, process, and asset through the use of advanced technology and analytics and through the ability to quickly assess and determine any modifications that are required and implemented within the digital twin model.

It enables organizations and the various teams within the organizations to view and share the same actual reality model so that decisions are quickly and accurately taken at each and every point.

In addition to problem resolution, realizing a digital twin vision paves the way for sustainable growth. With an increasing number of customization options or when growing from current operations, a digital twin will grow with the company. One can begin to think about what the future might bring or analyze “what if” questions using a digital twin risk-free virtual setting. In essence, realizing a digital twin vision not only provides for current solutions but also provides for intelligent operations in the long run.

Those organizations that take the step today put themselves in a leadership position relative to their competitors. They will gain the clarity, speed, and confidence necessary to innovate without pause. The alternative is to be left behind in a reactive rather than a proactive position relative to organizations that have already adapted a more transparent and connected model of operation.

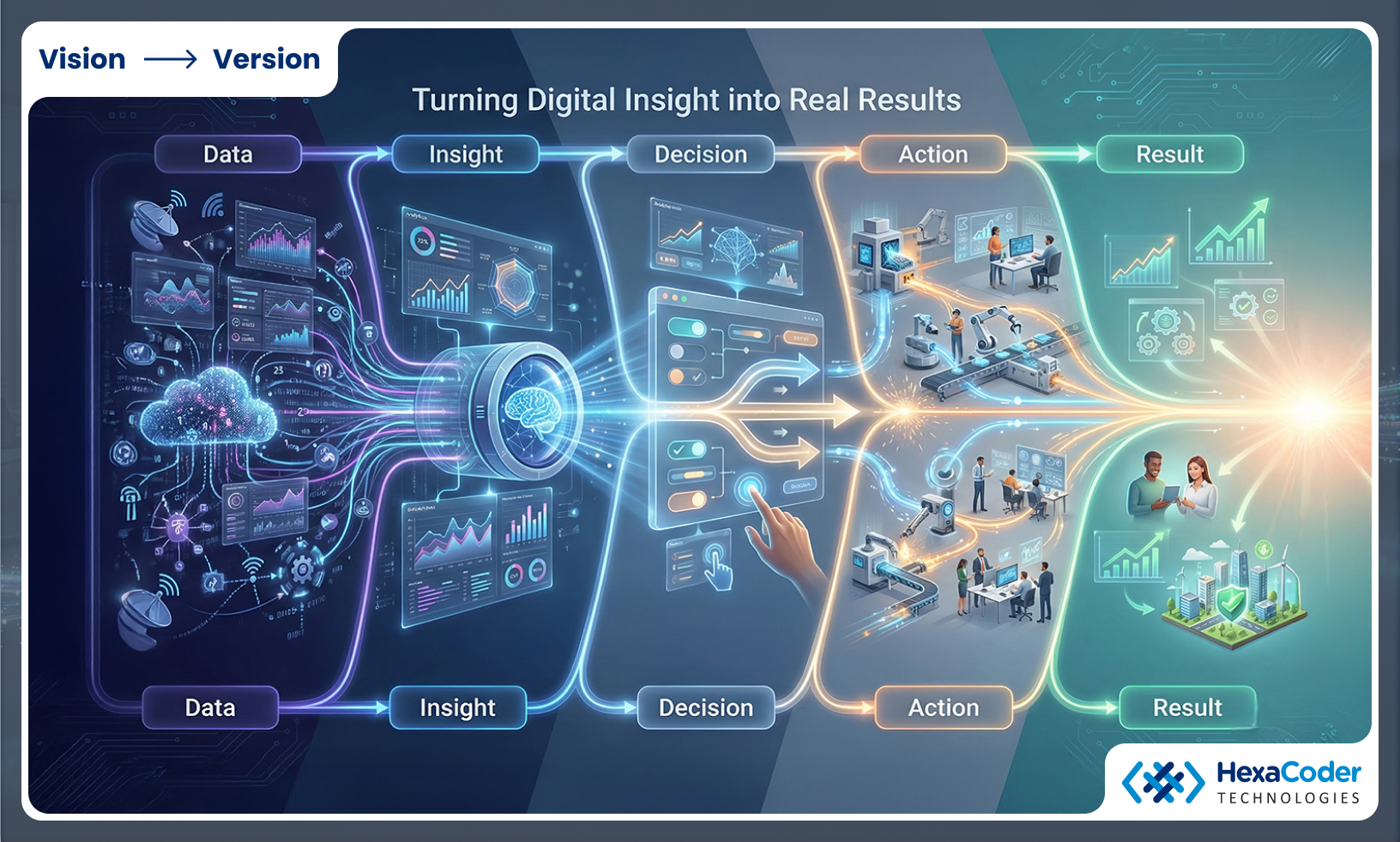

Turning Digital Insight into Real Results

A digital twin is more than just an application or a digital replica; it is an enabler that allows organizations to comprehend and optimize their offerings and business in real-time. Used effectively, a digital twin can completely redefine the way in which organizational decisions are made, team communications are handled, and products are developed.

The benefit is to leverage the twin as a common point of reference within the company. All of engineering, production, sales, and management work from the same common source of reference. There will be fewer misunderstandings, and processes will become more predictable; additionally, people will understand the consequences of their decisions before those decisions are made.

The implementation of the digital twin will also enable smarter planning and problem-solving. The teams will create scenarios and configure new settings and alternatives in a virtual manner, without the expense and risks involved in implementing in the physical world. The proactive method will eliminate errors and minimize the consumption of resources and schedules.

The advantage is not only reflected in the design process. Customers will also benefit because with a product or system that can be viewed and manipulated prior to its creation, clients will make informed decisions and will have greater confidence in those choices.

Timing is of the essence. Putting off the integration of a digital twin implies that an organization will continue to operate with scattered information, outdated documents, and guesses for information that is not known. This will mean that errors will take longer to correct, and chances to increase efficiency or seize a competitive edge will be lost. The use of a digital twin at the current time will enable an organization to stay ahead of the curve with regard to the complexity of modern products and operations that are being developed.

Finally, an “digital twin” is an ongoing investment in operational understanding and mastery. As it is kept current and fresh along with products and processes, it provides an ongoing foundation for innovation and excellence that stretches out into the future.

Digital twins and “smart factories are terms that come and go in fashion like “big data” and “Industry 4.0.” Industry experts debate if they are merely words that result in the creation of something else that will eventually become big and complex in its own right:

Companies that adopt digital twins effectively have a real advantage. They are able to make better-informed decisions, avoid risk, and achieve better outcomes for the business as a whole. For manufacturing executives, product managers, and technologists, a digital twin is no longer an optional or add-on piece of technology" but an integral part of a effective digital transformation strategy. View Your Products in a Completely New Dimension by Hexacoder Technologies Don’t let complexity hinder your teams or perplex your customers. With Hexacoder Technologies’ 3D Interactive & Digital Twin solutions, you and your organization can better visualize, analyze, and optimize each product down to the smallest detail. Your design and management teams and your customers alike can share a common workspace, minimizing mistakes and shortening product development timelines. Take the first step today. Discover Hexacoder’s solutions and bring your product ideas to life precisely, quickly, and confidently.