Digital Twins in Automobile Manufacturing Explained

Being an age when speed, precision, and innovation constitute a competitive edge, Digital Twins Automotive Technology is reshaping vehicle designing, testing, and delivery. For any automotive executive or strategist, this is more than just an upgrade in technology; it is a strategic leap that brings real-time data, predictive analytics, and AI onto the center stage of automobile manufacturing.

Essentially, a digital twin may be defined as a virtual replication of physical assets, production lines, or supply chains; through this, manufacturers may simulate scenarios, test changes, and detect inefficiency before that occurs in real life. These benefits extend across design accuracy to production downtime of automotive life.

Through collaborating with players like HexaCoder's Digital Twin Engineers, automotive companies can develop customized services for Digital Twin Development for their production ecosystems. This will, in turn, allow rapid prototyping, better resource allocation, predictive maintenance, and intelligent decision-making, thus shortening the entire go-to-market cycle while lowering operational risks and costs.

When applied correctly, digital twins become one of the key facilitators of Industry 4.0, ensuring automotive companies always remain in the front row of innovation and market leaders.

What Is Digital Twin in Automotive Manufacturing?

In its simplest form, a digital twin is an imitation of a physical object, process, or system continuously updated with data from the real world. In automotive manufacturing, this entails developing extremely accurate models of vehicles, assembly lines, engines, or even full plants.

Why it matters:

Differing from regular simulation, digital twins work in real-time. This hence encourages the manufacturers to test, forecast, and optimize processes, preventing expensive physical changes from ever needing to happen. They stand for curing a problem before it even gets big. Consequently, manufacturing quality grows, while time-to-market shrinks. Integration of IoT sensors, AI-powered analytics, and cloud computing lets digital twins duct deep into the operational aspects so decision-makers can minimize downtime, improve efficiency, and cut down production costs-all leading to faster and smoother market entry for new car models.

How Digital Twins Are Reshaping Automobile Manufacturing

Adoption of digital twin technologies for the automotive sector is making each phase of the manufacturing lifecycle cumbersome:

- Design Optimization

Digital twins allow engineering teams to run simulations of many design configurations without erecting a physical prototype. They simulate aerodynamics, structural integrity, crash safety, and energy efficiency, thus decreasing the design cycle time drastically with increased accuracy for each variant.

- Smart Production Lines

By having a digital twin representation of the assembly line, one can monitor machine health, optimize workflow, and identify bottlenecks. Companies such as HexaCoder specialize in integrating IoT data into these models to deliver predictive maintenance and adaptive production strategies.

- Real-Time Quality Control

Late discovery of defects claims heavy costs. In contrast, utilizing digital twins facilitates supervision on a continuous basis and helps to resolve deviations in product quality the moment they happen, diminishing the rework procedures, thus crowding increased customer satisfaction.

When an equipment breaks down, the deadlines are aborted, and expenses increase. Digital twins use sensor data to predict a failure, and thus they ensure minimal interruptions and maximum use of manufacturing assets.

- Sustainable manufacturing

With the tracking of energy consumption and material efficiency, digital twins aid manufacturers in reaching their sustainability goals to reduce their waste and operational costs, not to mention that this is done without any compromises in speed and quality of production.

Why Automotive Leaders Are Investing in Digital Twin Development Services

For automotive executives, digital twins are no longer a tech play but a profitability and competitiveness lever. In an industry dependent on speed, precision, and innovation, manufacturers gain strategic advantage by being able to bring together a blend of both physical-amplified and digital worlds.

Key Advantages For Businesses:

Reduced Time-To-Market : Quick prototyping and virtual testing, as well as an unhampered production workflow, allow the launch of new models to the clientele preceding that of their competitors.

Cost Efficiency : The design faults are caught during the early phases, and maintenance needs are anticipated to facilitate considerable reduction of R&D and operational costs.

Product Reliability : Real-time engineering trials give reviews based on actual performance data, thus strengthening criteria for strength and safety.

Improved Customer Experience : Manufacturers can offer custom vehicle configurations, adaptive performance, and predictive service, and create customer loyalty through such features.

With digital twins, innovative manufacturers are addressing sustainability targets through energy consumption in their factories, waste elimination throughout their supply chain, etc. This is in line with the significant demands for greener options from customers and aids in proper environmental compliance.

From concept modeling to IoT capabilities/capacity and predictive analytics, Hexa Coders provides knowledge for automotive digital-twin development services including specialized expertise. Our solutions are not just designed for travel and road-worthy purposes, they are constructed to grow in scale-the focus is to ensure that once digital twin implementations have been integrated, they will evolve through every phase of your business.

Hexa Coders produces automotive companies with an advantage with the innovations, reduces risks, and helps futureproof the manufacturing process amid competition from the evolving global economy.

Through a partnership with Hexa Coders, automotive companies can stay ahead in innovation, minimize risks, and future-proof their manufacturing operations in the increasingly competitive global market.

Technology Stack Behind Digital Twins in the Automotive Sector

To prepare for a successful digital twin automotive implementation, the act of gluing together many innovative systems is required. Each layer in the technology stack is critical in delivering accuracy, efficiencies and real-time agility. If any of the systems have latency, that will linger how much of a twin is really a simulation.

- IoT Sensors & Edge Devices

The deployed IoT sensors in the vehicle and in the manufacturing lines track important metrics continuously on temperature, vibration, pressure and performance. The edge devices locally aggregate and process the data to support quick decision making before relaying it to the cloud.

- Cloud Infrastructure

Scalable cloud infrastructure stores the entire data set providing support from many production plants and many vehicle fleets, managing, storing, processing, while allowing the engineering teams collaborate in real-time and allow for heavy simulation without the limitations of the infrastructure.

- AI & Machine Learning Engines

AI models will analyze incoming data, build user patterns, anticipate equipment failure, create optimal production schedules. The machine learning techniques enable better vehicle designs, better quality controls and reliable predictive maintenance techniques.

Professional CAD and simulation software accurately simulate the real-world physical asset and, before an actual prototype is created, have the ability to test the virtual designs against specifications for performance and safety criteria.

- Data Integration Platforms

Middleware, i.e. integration platforms, hook up functional enterprise systems, i.e. ERP, PLM, and MES, to get an enterprise long view of the operational state.

The Scope of Digital Twin at HexaCoder:

In our digital twin engineering, we offer the full range from data architecture designer, IoT hardware selection, AI simulation builders, to embedding our simulations into your existing systems. We bring the knowledge to make certain that the digital twin ecosystem installed is secure, scalable, and meets the automotive sector's demands perfectly. This totality allows market manufacturers to acquire variation in design cycles at significant operational risk, and respond to industry market changes in a once unimaginable agility.

Commercial Uses That Yield Real ROI

- Product Development & Testing: Virtual prototypes put pressure on potential applications for permitting virtual testing for comparative studies, like crash testing, aerodynamics, fuel economy and performance testing. This literally reduces physical testing time and expense and helps improve innovation cycles by speeding up product design.

- Factory Floor Efficiency: Quickly identify production line intrinsic inefficiencies and intentionally eliminate unplanned downtime through real-time visibility. This increases throughput and allows for better utilization of resources.

- After-sales and Predictive Services: A real-time digital twin model of each vehicle to anticipate maintenance needs enables the provision of proactive service packages to improve customer loyalty and increase opportunities for repeat revenue.

Use Case: Competitive Advantage with Digital Twins

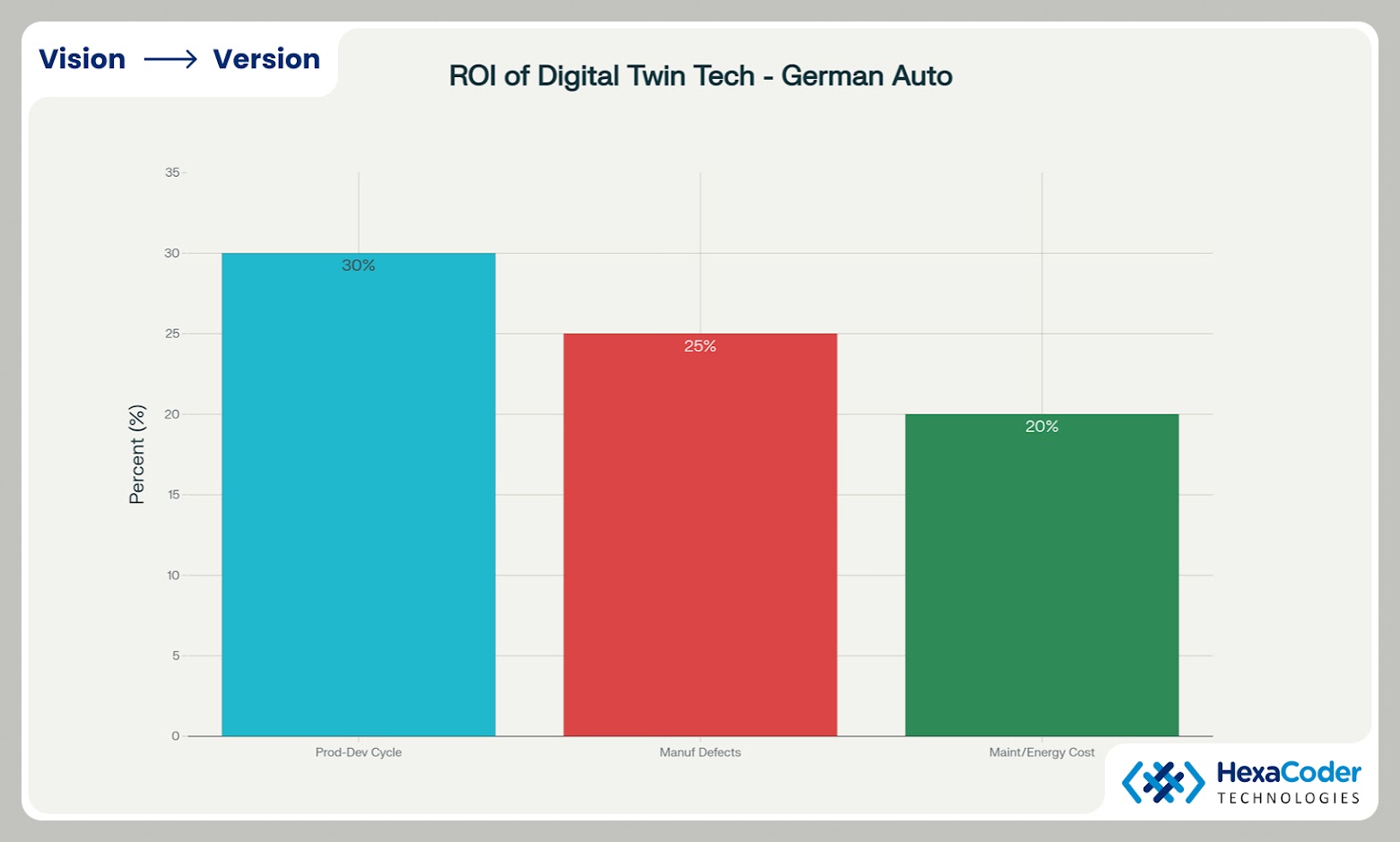

German automotive brands that are implementing Digital Twin Automotive Technology have some data to back up their ROI:

- 30% reduction on the product-development life-cycle

- 25% reduction in manufacturing defects

- 20% reduction in maintenance and energy costs

HexaCoder sees that while top tier OEMs have contributed early implementations, we need to democratize the capabilities of digital twins with our Digital Twin Automotive Development Services. We offer the ability to assist mid-sized and up-an-coming automotive makers to implement efficient, scalable technology solutions with limited capital cost -- not the HUGE cost typical with cutting-edge technology.

When applied properly, digital twins move from the "like-to-have" category of cute and useless innovations, to becoming the catalysts of innovation, profits, and long-term leadership.

HexaCoder Methodology for digital twin in automotive development services

HexaCoder utilizes a tested and proven methodology with 4 phases in partnership with the client to expedite their mode of operation and design. In doing so, automotive organizations can utilize fully the advantages of digital twin technology and conveniently ease into the intelligent manufacturing from their traditional mode of operation with the help of data.

- Assessment & Strategy

As part of this phase holistic assessment of the manufacturing processes is completed. Their operational activities and long-term vision for the factory are referenced to determine high impact cases for design, production, or after-sales applications. This ensures the digital twin strategy is developed with expected observable ROI.

- Creating a digital model

The job of our team is to create highly accurate virtual accurate 3D representations of vehicles, machinery, or production plants. These virtual models are combined with IoT sensors and real-time data streams to provide a dynamic live representation of the physical assets, offering support to monitor actions and facilitate business decision-making.

- Implementation & Integration

Confirm that the digital twin framework is integrated with ERP, MES, PLM, and production processes. We have taken every precaution to mitigate interruptions to operations, while information from the departments flows to allow them to work as one single platform for analytics.

- Monitoring and Optimization

After the system is deployed, it is machine learning analytics enabled to evaluate how it is performing, identify inefficiencies and predict failures pre-emptively. You can continue to optimize the outdated digital twin to better adapt its operations for results in productivity, quality, and cost sustainability.

With HexaCoder, automotive firms can digitize from the ground up or modernize to scale in modular, scale-able solutions — simultaneously putting a foundation in place for future digital success while not overextending their resources.

Challenges & How to Overcome Them

While Digital Twins Automotive Technology has the potential to bring great power as a technology able to bring real change there are a couple of challenges that will be presented as the technology adapts to its operating environment and moves towards being accepted into the mainstream.

- Data Silos & Integration Difficulties

To support a digital twin, continuous and clean data from design, building and operational systems is essential. Each department functions with their own silo of data which diminishes the associated twin's ability to be completely accurate and useful.

Solution: HexaCoder's Digital Twin Development Services identify ERP, PLM, IoT and MES implementations that can amalgamate all streams of data in real-time and create a single pipeline to use it in decision making.

- High upfront costs

Traditional implementations fall under the burden of significant investment in infrastructure and software, which means this may simply be out of reach for a smaller manufacturer.

Solution: Our modular and scalable architecture allows you to start anywhere - perhaps a single production line or a specific vehicle model - and grow from there as ROI is realized, reducing the financial risk.

- Workforce Training & Change Management

Even the most progressive systems of change can be rendered useless by inefficiencies of team members using them too slowly.

Solution: HexaCoder delivers immersive training sessions for onboarding and developing skills, so engineers, operators, and managers can benefit and get the most out of the platform.

These are just a few of the objections we need to deal with upfront, and make HexaCoder’s deployments simple, on time, and quickly pay back money and time when operating and gaining a competitive advantage in an automotive world that is changing constantly.

The Future of Digital Twins in Automotive

Going forward, Digital Twins Automotive Technology will far eclipse its present manufacturing-oriented capabilities. They will become the nerve center for vehicle lifecycle management over the next decade — monitoring performance, wear patterns, and maintenance requirements all through the life of a car. Continuous on-road feedback from vehicles to design teams shall also enable the connected car ecosystem to facilitate over-the-air updates and spur quick improvements.

Thinking most significantly, digital twins will ultimately be at the heart of autonomous-drive simulations, allowing manufacturers to test tens of millions of scenarios "what if"-from extreme weather conditions to complex traffic patterns-without any risk to physical assets.

Thus for automotive executives, early adoption is not just about meeting efficiencies. It is about shaping the future competitive landscape because anything which is not being done on data-driven manufacturing is going to be utterly irrelevant today and those who delay are at a point of no return.

Conclusion: Driving Innovation with HexaCoder

Digital Twins Automotive Technology is no longer a futuristic concept - it is, in fact, the base of today's automotive excellence. In other words, leaders who take this on today provide their business with an edge towards operational precision, cost efficiency, and further sustainability.

Through the digital twin automotive development services of HexaCoder, manufacturers can:

Speed up innovation cycles between design and production.

Mitigate operational risks using predictive analytics and real-time monitoring.

Develop an agile production ecosystem with the ability to shift their focus according to market requirements.

On the way to re-define automotive manufacturing, those who embed digital intelligence along the whole value chain from concept to customer will win. The future production line unfolds right now, and HexaCoder is ready to design it alongside you.