What is a Real Example of a Digital Twin?

Digital transformation has unleashed some disruptive technologies throughout various industries, few of which have impacted aerospace with more force than the implementation of a digital twin. A digital twin is an actual virtual copying of a physical asset, system, or process, the nature of which mirrors the real-world behavior in real-time. It integrates data streams, simulation software, and AI-driven analytics to arrive at a living, evolving model that aids design, operations, and maintenance.

For aerospace engineers and aviation professionals today, digital twins are no longer mere futuristic ideas; the application spans aircraft manufacturing, predictive maintenance, air traffic systems, and even passenger experience optimization. Airline operators use twins to monitor engine health, reduce unscheduled maintenance, and improve fuel efficiency. Airbus and other aircraft manufacturers use them to simulate production lines, conduct virtual aerodynamic tests, and speed up the certification procedure. On the other hand, airports themselves create digital twins of terminal buildings to optimize passenger flows and reduce congestion. To understand the power of this technology, let us understand a real-world example of a digital twin in aviation, its benefits, and how specialized firms like Hexacoder make enterprise-grade twin implementation possible.

The Rise of Digital Twins in Aerospace

The aerospace sector is uniquely poised to benefit from digital twins. Aircraft remain complex machines of millions of interrelated parts, operating in safety-critical environments where downtime is expensive. In cases, conventional monitoring and maintenance have proven to be good but in most that are not good at timely detection of a failure before it happens.

The emergence of IoT sensors, simulation softwares, and advanced analytics has made it possible for aerospace firms to create digital twin counterparts for aircraft engines, avionics systems, flight control units, and whole fleets. These twins are constantly ingesting data from sensors and operating environments, simulating possible outcomes, and generating predictive insights. This is what has rendered digital twins so much more apt in averting failures, reducing costs, and provisioning for safer skies.

What differentiates digital twins is the ability to create a “living model” of the aircraft that adapts in real-time. That is, each takeoff, landing, and mid-air maneuver generates data funneled back into the twin. And now, engineers can utilize this feedback to assess performance, catch anomalies early, and optimize maintenance scheduling. This is great for airlines as it cuts down unplanned breakdowns and helps in peaking asset utilization. Further combining simulation with AI, these twins have evolved beyond being passive monitors to actively suggesting operational adjustments to reduce fuel consumption, extend part lifecycle, and comply with regulatory safety standards.

Example Real: Digital Twin for an Engine

One of the chief reasons why digital twin technology has gained commercial attention is Rolls-Royce's digital twin for aircraft engines. The company is likely to be one of the greatest engine manufacturers, and Rolls-Royce was among the first client groups to implement this technology employed for real-time monitoring of an engine under flight conditions. Some hundreds of sensors are installed on each engine and monitor parameters like temperature, vibration, fuel efficiency, and stressing on components.

These sensors feed massive streams of data back to the ground control system, where simulation software creates the virtual twin of that engine. The digital twin looks into problems of wear-and-tear and can detect anomalies, putting in place maintenance recommendations or alerts about possible maintenance before it is needed.

For airlines, this has transformed maintenance models from reactive to preventative. Instead of waiting for a scheduled service check or reacting to an unexpected breakdown, the engineering team now receives early warning. If a turbine blade mindlessly goes through vibration patterns unusual in nature, then the digital twin tests those scenarios for probable outcomes and warns technicians to intervene before catastrophic failure occurs.

There has been a good amount of downtime reduction and cost savings through this approach. The Rolls-Royce digital twin program has, in fact, saved millions through unplanned repairs and extended the life of engines. This is a textbook example of how a digital twin can assist in the predictive maintenance process in aerospace.

Beyond Engines: Aircraft-Wide Twins

Engines being a natural departure point for selecting digital twins presently, aerospace manufacturers and airlines are creating digital twins at the level of the entire aircraft. Airbus, for instance, has heavily invested in building digital twins of complete aircraft structures. Considering cabin layouts, electrical systems, stress models on the fuselage, and even environmental control systems, these digital twins are built at several environmental levels.

Simulation software enables engineers to predict how design changes—such as a new seat configuration, cargo area reconfiguration, or additional integration of fuel-efficient propulsion systems—would affect actual performance long before physical prototypes are put together. It is a process that conceals great cost implications, shortens design time, and eliminates the risks typically associated with trial-and-error testing.

Benefits mitigate to air transportation fields, mostly in day-to-day scenarios. By creating a digital twin, one can explore how the plane reacts to turbulence or check the state of structural fatigue in real-time or maybe project scenarios when an onboard system might need repair. Thus, flights become safer with better fuel consumptions, while the whole passenger system gets optimized to suit present-day demands.

Simulation Software in Action

Simulation software is in the heart of every digital twin. In aerospace, the likes of Ansys, Siemens NX, and Dassault Systèmes' 3DEXPERIENCE are some of the simulation tools that mimic fluids, static materials, and airforces in real life. But traditional simulation software is run in airtight rooms. In a real digital twin, integration of simulation with real sensor data and AI analytics creates a continuously evolving model

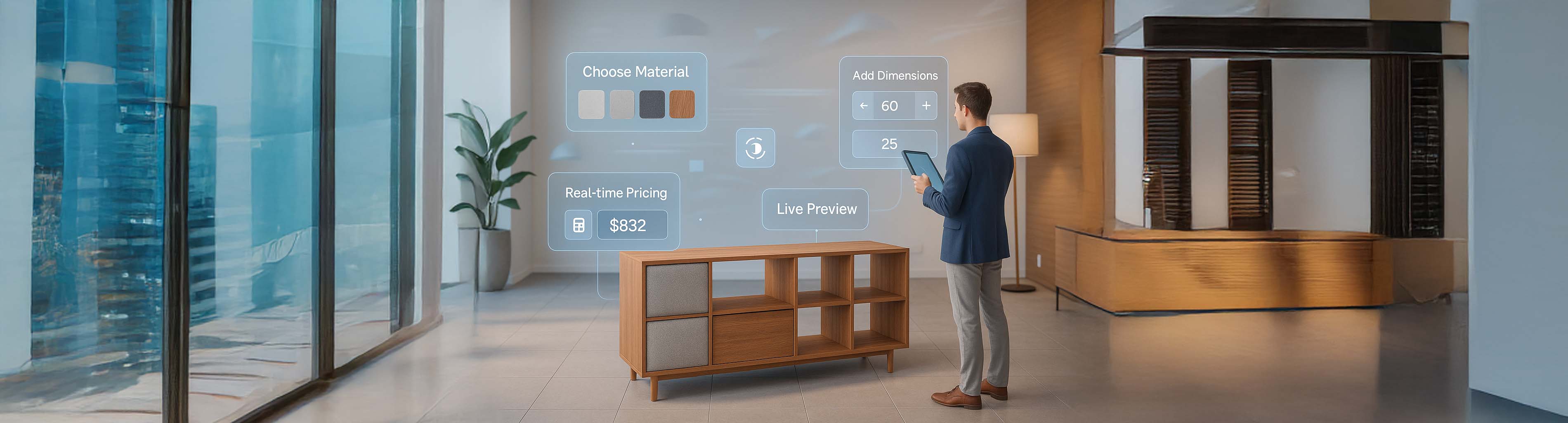

This is the mark of dint modernization Twin builders such as Hexacoder. Using 3D visualization, WebGL interfaces, and frameworks for predictive modeling, Hexacoder simultaneously garanties that aerospace twins remain mathematically accurate, immersive, and usable by engineers or those making decisions. Instead of wandering through raw data, professionals go through easy-to-understand dashboards and immersive 3D models to make maintenance decisions swiftly and with confidence.

Apart from operational support, such advanced simulations engage in scenario testing and predictive maintenance. Engineers simulated for extreme weather, tested out design changes without prototypes, and predicted the failures of operational components with plenty of foresight. Such possibilities now shave away experimentally expensive trials, thereby cutting down developing time and increasing the margin of safety. In the long run, fuel efficiency offered to airlines, flight delays, and increased reliability of the aircraft by aerospace concerns. Hexacoder tries to break this dichotomy by turning static simulations into living and learning systems that continuously evolve as aircraft data flows in.

Benefits of Having a Digital Twin for Predictive Maintenance

For aerospace engineers and aviation professionals, predictive maintenance stands out as the most prominent application of digital twins. The benefits can be summarized as follows:

Failure Detection at an Early Stage

With continuous sensor data collection, digital twins monitor engines, landing gear, and avionics systems. It is the work of an advanced simulation software tool to detect anomalies even the slightest ones; thus, engineers are able to warn of failure days or weeks in advance and timely take actions to prevent breakdowns that would interfere with flight schedules.

Reduced Downtime

Any sudden fault-induced grounding of an aircraft means millions in daily losses to an airline. With foresight built into a digital twin, the maintenance could be planned for already planned windows for service, thus limiting any sudden malfunctions. This would in turn enhance the hours available for fleet utilization and optimize overall operational efficiency.

Lower Maintenance Costs

Emergency repairs and grounding of an aircraft impose heavy cost burdens. Digital twin technology mitigates such risks by early failure prediction to allow cost-effective planning of interventions. This leads to the reduced maintenance expenditure incurred by airlines in the long run, along with cost of spare parts procurement, crew deployment, and optimizations of all sorts.

Extended Component Life

Simulation-driven monitoring may show how, under certain conditions of high altitude or frequent take-offs, engines and components suffer more wear and tear. Properly adjusting operating patterns from the knowledge of such effects prolongs component life, delays replacement, and offsets other capital expenses considered under safety terms.

Better Safety

In the world of aviation, safety is paramount. Digital twin-enhanced safety simulates critical scenarios through continuous monitoring of real-time performance. It predicts potential faults before their actual occurrence so flights can be made safer, having fewer in-flight emergencies and hence greater acceptance by regulators, pilots, and passengers alike worldwide.

The Commercial Use of Predictive Maintenance for an Airline

Consider a global airline, which operates in many long-haul air services. Thousands of Pbytes of flight data are streamed daily off the aircraft engines. Earlier, engineers analyzed infinitesimal subsets of this data after a particular flight. Now, being implemented with digital twins, all data goes into cloud models in real-time.

In the event of an aircraft behaving abnormally with fuel burn, the twin may try and simulate various scenarios: clogged fuel nozzle, faulty sensor, or some truly unusual weather! In a matter of minutes, the twin reaches a conclusion and suggests the action.

The ground engineers thus get the maintenance job down to the minute as they wait for the aircraft to land, with no unnecessary downtime. The immediate ROI for airlines is digital twin technology:definitely lower fuel costs, better fleet availability, and happier passengers with fewer delays.

While front-runners like Rolls-Royce and Airbus have invested billions in digital twin ecosystems, not every aviation enterprise has the same resources. This is where specialized digital twin service providers like Hexacoder become the critical partner.

Why Hexacoder Stands Out in Aerospace

Cross-domain expertise: Hexacoder delivers digital twins across engines, avionics, and ground systems, ensuring aerospace enterprises benefit from tailored, domain-specific solutions rather than one-size-fits-all implementations.

Simulation + Real-time integration: Their platform unites advanced simulation with IoT streaming data, ensuring digital twins remain dynamic, continuously learning, and reflecting real-world conditions instead of being static models.

Immersive interfaces: Hexacoder builds 3D dashboards that are engineer-friendly in preparation for user engagement through three.js, WebGL, and XR, simplifying complex data visualizations for immediate interpretation and practical application in critical decision-making.

AI-powered predictive analytics: By leveraging AI models to detect early warnings of anomalies, Hexacoder turns sensor streams in real-time into predictive maintenance alerts, thereby reducing downtime for an entire fleet or particular aircraft components.

Scalable architecture: Their modular systems can scale from a twin of a single subsystem to an enterprise-wide fleet management system, ensuring that the growing needs of the aviation sector can be accommodated without throwing a wrench into the existing tech stack.

By adopting an early engagement with their customers through visioning workshops, pilot programs, and enterprise-wide rollouts, Hexacoder ensures that aviation-related businesses make the most out of their investments in digital twin technology.

The Future of Digital Twins in Aerospace

The real-world cases we touched on—jet engine twins, fleet-wide twins, and predictive maintenance models—are just scratching the surface. The future of aerospace digital twins looks even more challenging:

Air Traffic Control Twins

Unlike the present ones, digital twins will not be simulating individual planes but the entire airspaces. By simulating these complex flight networks, they optimize routes to reduce congestion and delays, thereby helping airlines cut down on fuel expenses, improve passenger punctuality, and greatly reduce unnecessary carbon emissions.

Passenger Experience Twins

Cabin comfort is critical for long-haul flights. Twins gauge real-time changes in airflow, lighting, noise levels, and even passenger biometrics. Airlines could use the data to customize services, tighten safety measures, and boost the overall experience while trimming down operational inefficiencies.

Sustainability Applications

Aerospace is being reshaped by environmental pressures. Digital twins allow engineers to simulate sustainable aviation fuels, lighter composites, and aerodynamic changes before physically implementing the tests. This helps speed up the adoption of greener technologies so the industry can meet stringent emission regulations while keeping operational costs down in the long run.

Twin AI-Augmentation

Companies like Hexacoder foster the further development of AI and machine learning-augmented twins. These self-adaptive systems tailor themselves to real-world changes, anticipate failure with greater lead time, and fine-tune aircraft performance toward the creation of smart and autonomous aviation ecosystems across the globe.

Acknowledging AI goodbye for a new paradigm of augmented digital twins that are operative in self-learning, seeking adaptation, and evolving in real time-a step towards full implementation of autonomous and sustainable aviation ecosystems in aerospace.

Conclusion

A digital twin used in an aerospace scenario was offered by Rolls-Royce with the design and utilization of the engine monitoring system that brought together simulation software, IoT, and AI to solve critically important aviation problems. The advantages of using a predictive maintenance digital twin are numerous-the fewer failures, the lesser the costs, the greater the safety, and the longer the life span of the assets.

In the eyes of the aviation fraternity, it must be crystal clear that digital twins are not in the realm of experimental but have proven their mettle commercially and are presently affecting the industry.

As adoption continues to spread beyond the aviation giants, partners like Hexacoder further extend digital twin adoption to the likes of airlines, aerospace OEMs, and MROs worldwide. The Hexacoder modern tech stack, along with CDK interfaces and predictive analytics credits, shall enable aerospace organizations to fly smarter, safer, and more sustainably into the future.