Is SpaceX Using Digital Twin Tech? Exploring Their Use in Starship Production

In our fast-growing world of space making, real tech jumps are key to push what is new and make things happen. Among these jumps, digital twin tech is very useful, as it lets teams make live, online copies of real things and how they work. The good thing about digital twin tech is it lets us see how things work in real-time, test ideas before, and guess what may happen next, which helps make things run better.

With SpaceX always keeping things quiet about its bold aims in making Starships, it's hard to know what they do. But, using digital twin tech would match well with how they work: fast changes, choices based on data, and using resources well.

This piece looks at how SpaceX might be mixing digital twin tech in making Starships, the need for simulating and modeling in aerospace, and how firms like Hexacoder help in doing these jobs fast and well.

What is Digital Twin Techology?

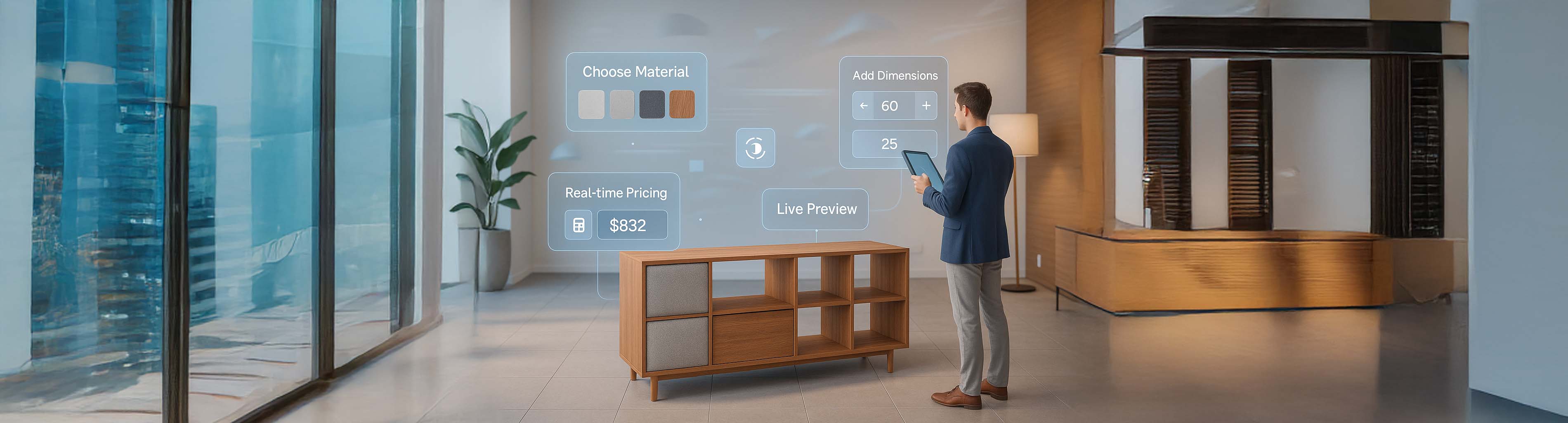

A digital twin is basically a live, always changing online copy of a real thing or action, which is always updated from real-time data. Digital twin tech starts from mixing sensors, old data, copy models, and IoT-enabled data smarts.

In aerospace, a digital twin can show anything from a single rocket engine part, to a whole spacecraft or launch site. Digital twins let engineers and users track system health, guess likely fails, try different situations, and make the most value, all without a real test (which saves a lot of money and time each time). At its heart, digital twin tech will have:

Real-Time Data Integration:

The digital twin always gets live data via sensors on the real item. This makes sure the online model always shows its latest state, but it also lets engineers see how things work in real-time, find problems early, and make smart choices with the trust of up-to-date tech data without waiting for manual checks or tuning.

Improved Simulations:

Digital twins can use real and learned sim models to catch the complex ways aerospace parts act in different environments and work conditions. Digital twins let engineering teams do 'online tests' against harsh conditions and cut the need for very costly real models. They also speed up design check processes with spot-on guesses of likely results that allow for action.

Predictive Analytics

As part of digital twins, AI and machine learning looks at old and real-time data to set future work paths. Predictive analytics lets pros see failures before they happen, plan upkeep schedules to dodge unplanned downtime, and reach higher levels of trust and safety in aerospace work.

Life Cycle Management:

Digital twin tech helps manage items through their whole life from design to making to use and to breaking down. The digital twin gives ongoing feedback that notes better designs, makes making and using items (work) better, and makes sure that item check decisions at the end of life bring the most chances to make sure the item is sustainable through the life circle.

Accelerating Design Integration and Validation

Digital twins let aerospace engineers test many design choices online, saving them from costly model work. By simulating key parts of the design like heat stress, air forces, shaking, and material wear, teams can spot likely fails early in making. A change process like this one cuts down time to market as engineers will be able to quickly tweak and better designs, thus speeding up making steps while raising product trust and quality.

Increasing Manufacturing Efficiency

Manufacturing an aerospace vehicle involves intricate assembly lines and uses precision tooling that handles thousands of parts. Digital twins duplicate the production facility using virtual space to construct a workflow, resource allocation, and usage of production equipment. Once continuous improvement activity occurs through experience-based data, manufacturers can isolate bottlenecks and find use of labor and enhance accuracy in assembly. Manufacturing intelligence becomes necessary, particularly with extremely complex programs such as SpaceX's Starship to easily increase production rates with consistent quality.

Predictive Maintenance and Reliability

Downtime can devastate aerospace operations and be extremely costly. Digital twins use real-time telemetry and sensor data to continuously track the health of critical components during operation. Artificial Intelligence (AI) and machine learning (ML) technology can process these streams of realtime data to predict failures before they occur. This predictive maintenance model allows for repairs and part replacements to be scheduled proactively, prevents unplanned outages, increases asset longevity, and provides confidence in mission readiness.

Improving Safety and Mission Success Rates

Safety is the foundation of aerospace engineering. A digital twin allows extreme environments, faults, and emergency response conditions to be simulated in a virtual environment. This allows engineers and mission planners to identify system weaknesses and validate design margins and fault tolerance before the mission is carried out. For missions involving crewed and valuable payloads, this means not only can the mission be accomplished with greater confidence of success, human lives, and assets are better protected.

These compelling improvements show why digital twin technology has become crucial to aerospace engineering. Virtual experiments allow manufacturers to avoid missed opportunities from expensive trial and error phases, challenge assumptions faster, foster innovation faster, without impact on safety or quality.

Hexacoder Technologies is aware of the challenges and nuances of developing aerospace digital twins. From sensor integration, modeling in simulation, data analytics powered by AI, to systems integration, we offer customized services. We work with aerospace innovators to speed up the implementation and successful deployment of digital twin technology—turning dreams to delivery, and enabling our clients to remain competitive in such a demanding market.

How SpaceX Utilizes Digital Twin Technology for Starship

Although SpaceX does not disclose its engineering tools, most industry experts agree that digital twin technology is part of SpaceX's development process. Here is an example of how SpaceX may be using digital twins across the Starship program.

Simulation of Complex Flight Dynamics

Starship’s design is based on novel materials, reusable systems, and unique flight profiles. Digital twins are used to simulate the launch, ascent, reentry, and landing dynamics for in-flight verification of performance and structural integrity for each of the conditions.

The information that comes from the simulation may also be extremely valuable for fine-tuning control algorithms and predicting flight performance across flight profiles. This will enable SpaceX to reduce its reliance on costly and time-consuming physical flight test articles.

Real-Time Structural Health Monitoring

Starship prototypes have embedded sensors that record information, such as stress loads, temperature, vibration, and pressure, and this data is transmitted in real time. The telemetry data is integrated into digital twin models that continuously monitor the structural health assessments and status of the components. If there are any anomalies, engineers will be alerted before things are out of control.

Being able to monitor the spacecraft in a near real-time capacity is essential for safety and determining maintenance and refurbishment for each flight.

Manufacturing and Assembly Optimization

Digital twins model the environment of the production line for the components of the Starship being fabricated and assembled. With modeling of their workflows between processes and utilization of equipment, SpaceX is able to find inefficiencies and improve their allocation of resources.

This will allow for faster build turn times, and quality assurance, which is critical when trying to achieve a quick turn around of a reusable launch vehicle.

Predictive Maintenance Scheduling

The implications of cost and safety for spacecraft maintenance is sizable. SpaceX's digital twins also likely consider its usages and stress histories, in order to promote inspections or replacements without unnecessary downtime or assuming never ending operational readiness with faulty or wear-infused components.

The Role of Simulation and Modeling in SpaceX’s Digital Twin Strategy

Simulation and modeling are at the core of any digital twins approach in the aerospace industry. For the development of the Starship, simulation include:

Finite Element Analysis (FEA)

FEA models aid in understanding how the Starship structure will perform under mechanical loading, thermal gradients, and dynamic loads. This is essential to understand whether the components can withstand the harsh conditions of a launch and spaceflight. FEA modelling provides insight into stress patterns across the material, as well as deformations under complex loadings. FEA enables engineers to identify potential failure modes and ultimately allow the build-up of the structure to be 'optimized' to reinforced materials without the expense of physical testing.

Computational Fluid Dynamics (CFD)

CFD simulations enable the analysis of airflows around the Starship during both ascent and reentry. These analyses allow engineers to optimize the aerodynamic shape and the performance of the heat shield. These simulations aid in reducing drag, enhancing stability, and improving performance regarding extreme temperatures. CFD also gives engineers the ability to review multiple flight conditions (supersonic and hypersonic), or speeds, which help develop controls surfaces and enhancements to fuel efficiency.

Systems Engineering Models

The Starship includes complex propulsion, avionics, and control systems. In order to model these systems and their various interactions, it is necessary to run models that encompass the entire system to be able to optimize the system as a whole, and establish fault models, and validate the system prior to real-world integration. Having the ability to simulate the subsystems and their actions as they impact the broader spacecraft are essential to demonstrating proper interfacing of the engines and fuel systems.

Thermal and Environmental Simulations

Starship experiences extreme thermal environments during reentry and routine operations in space. As such, thermal modeling and simulation are essential. Understanding heat transfer, insulation performance, and thermal stresses allows for confident flight spacing. Similar to thermal modeling, environmental modeling, including radiation exposure and micrometeoroid impacts, are relevant to crew safety and equipment performance.

Virtual Prototyping and Scenario Testing

Digital twins allow space travel for virtual prototyping. These twins can be leveraged to simulate SpaceX's mission scenarios including launch aborts, emergency landings, and maneuvers during docking. With each simulation reducing the cost of prototyping and decision-making while increasing the identification of design issues and operational risks during the development cycle, SpaceX speeds up the design process and reduces costs.

Integration with Real-time Data

SpaceX is undoubtedly linking these simulation models with the real-time telemetry data from the test flights and prototypes to continuously improving the digital twin model, making it more accurate as time passes. Furthermore, this practice also provides the opportunity for real-time decisions and adaptive control during the testing phases and the operational phases.

Hexacoder: Modernizing Aerospace Innovators with Digital Twin Development Services

In today's aerospace industry, precision, safety, and innovation hold high value, making improved digital twin technologies a necessity. While trailblazers like SpaceX make the challenge of digital twin development look easy, many aerospace companies and suppliers are still looking for specialized know-how to successfully adopt and implement digital twin solutions that help fulfill their operational requirements. This is where Hexacoder Technologies can be a trusted partner.

Hexacoder provides a comprehensive range of digital twin development services for the aerospace market. Its solutions help empower organizations to utilize real-time data effectively, perform simulations, and enabling predictive analytics, allowing them to make smarter decisions and operate more efficiently.

Customized Digital Twin Development

As needed, Hexacoder's team works closely with its aerospace clients to develop customized digital twin configurations. Whether it is simply modeling a subsystem (like a propulsion unit) or creating a full digital twin of a space vehicle, the Hexacoder team's goal is to get the virtual twin to represent the real-world operational performance as closely as possible. Doing so provides the client with the ability to solve the specific problems unique to their mission profiles and engineering limitations

Integration of IoT Sensors for Real-Time Synchronization

The more accurate and instantaneous data flows into a digital twin, the more effectively it works. Hexacoder performs at the highest level in integrating IoT sensors into aerospace asset telemetry systems with functioning data streaming in real-time. The real-time synchronization between the physical and virtual systems is crucial for digital twins in keeping their operational status reflections accurate, hence enabling the immediate pinpointing of faults and rapid response actions.

Interface for High-Level Simulation

Hexacoder integrates top-level simulation tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) with systems engineering models into the digital twin environment, allowing them to physically model occurrences of aerospace vehicles. Their unified approach lets the user perform virtual stress tests and study air movement while simultaneously looking at how systems interact-all from a single platform. This saves on physical models and also cuts down on execution time for design improvements.

AI-Powered Predictive Insights

At Hexacoder, ML and AI use both historical and fresh data to provide insights into predictive maintenance and asset-enhancement suggestions. High-end analytics at Hexacoder can forecast the wear and tear of certain parts while detecting early symptoms of issues, and thus plan maintenance activities for better utilization of assets while lowering costs in the long term.

Linking Systems in Companies

Knowing that digital twins are meant to work with already-existing infrastructure of companies, Hexacoder makes sure it fills with MES, PLM, and ERP platforms. This link gives a view of making things to supply chains and finally to their running. It aligns workflows and supports smart decision-making across the company.

Competitive Advantage

Building and collaborating with Hexacoder provide aerospace companies with the most flexible, scalable, and future-ready digital twin setup. This expedites innovation while trimming development costs. It also enhances operational efficiency and reliability-a point critical to very precise and safety-oriented fields.

Hexacoder's expertise aids aerospace innovators in merging real-world and digital insights to stay prepared and ahead in a tech-intensive environment.

Challenges to Adopting Aerospace Digital Twins

The aerospace digital twin domain has its thorny points:

Data Volume and Variety

Spacecraft produce large volumes of mixed data. Managing, treating, and extracting useful information needs a scalable cloud setup and sophisticated analytics that Hexacoder provides.

Integrating with Legacy Systems

Most aerospace companies, in all likelihood, already have legacy systems. Hexacoder offers intermediary solutions that enable integrating digital twins into legacy systems without disrupting the existing working.

Training Workers

Bringing in digital twin tech needs new skills for engineering and running things. Hexacoder provides training to make sure teams get the most out of these new solutions.

Cost and Being Able to Expand

While the first money spent is big, Hexacoder's step-by-step way lets clients grow their digital twin powers slowly, making sure they get their money's worth every time.

Future Changes in Digital Twins for Aerospace and SpaceX’s Plans

Luminosity will transit at a higher orbit in front of a tech storm past just the asset-level digital twins that get transformed today:

- Self-running Operations: Helping spacecraft move and make choices by themselves during missions

- Team Work Supply Chains: Bringing together digital twins with suppliers, makers, and runners for lined-up production and upkeep.

- Tracking Green Efforts: Watching the environmental toll and usage of resources in aerospace life.

With SpaceX's drive to innovate, it continues to be up-to-date on this change, while Hexacoder empowers aerospace firms around the globe to become part of this digital transition.

End Thought: Pushing Aerospace Forward Through Digital Twins and Hexacoder

Digital twins are revolutionizing how teams design, manufacture, operate, and maintain complex spacecraft. SpaceX's new way of doing things through Starship truly captures the big shift of real-time simulating, modeling, and predictive insight.

For aerospace companies that want this technology, partnering with an established player like Hexacoder Technologies will ensure that they get the very best digital twin-making services tailor-made to the needs of the industry.

Hexacoder's expertise, therefore, gives clients the freedom to speed up new concept development, reduce costs, enhance safety, and attain the optimum operation of their aerospace assets throughout their life.