Introduction

The cement industry is going through pressure. The demand for infrastructure is rising, expenses are increasing and sustainability expectations are higher than ever. Meeting these challenges means pushing plants to produce more without sacrificing quality, safety or efficiency.

That is where digital twins technology comes in. By creating a visual replica of a cement plant, operators can test, predict, and change every part of a production process before making changes in reality. From optimizing kiln performance to predicting maintenance needs, digital twins are proven to be a game changer for scaling capacity while controlling cost and cutting emissions.

This article will explore how cement producers can use digital twins to expand output, improve efficiency and stay very competitive in an industry that is shaped by technology and sustainability goals.

The Pressure To Scale Cement Production

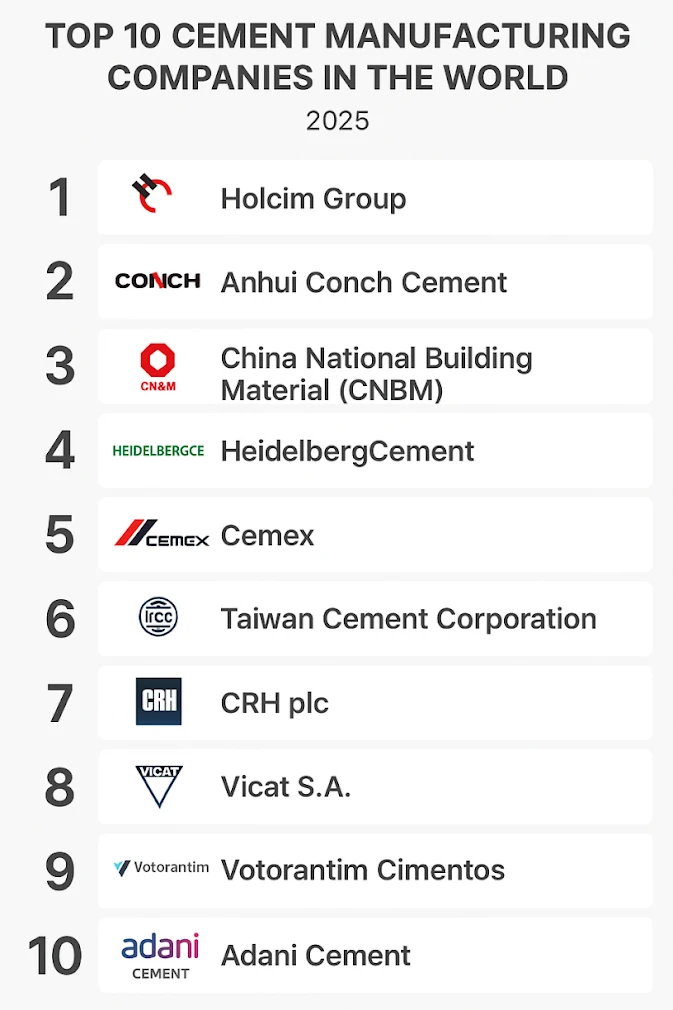

Cement is one of the most important building blocks of modern infrastructure. From roads and Bridges to housing industrial projects, global demand shows no sign of slowing. In fact, with urbanization and large scale development projects underway across Asia, Africa, and the Middle East, cement demand is projected to steadily rise over the next 10 years.

For producers, this means scaling of capacity is no longer a matter of choice, it should be the air you breathe. But expansions comes with challenges like:

Energy Consumption

Cement plants are among the most energy intensive facilities in the world, often accounting for a large share of industry emission.

Equipment Stress

Running kilns, grinders and conveyors at higher load pushes machine closer to their limit which leads to costly break downs if not carefully managed.

Quality Consistency

Producing more cement and scale must not affect the strength, durability or uniformity expected by construction projects.

Sustainability Pressures

Investors, regulators and communities are increasingly demanding greener cement with reduced carbon footprints.

Traditional methods like trial and error process adjustment, manual monitoring or reactive maintenance are no longer enough. They make progress slow, add more risk and makes scaling more expensive.

This is exactly where digital twins technology offers a new path forward.

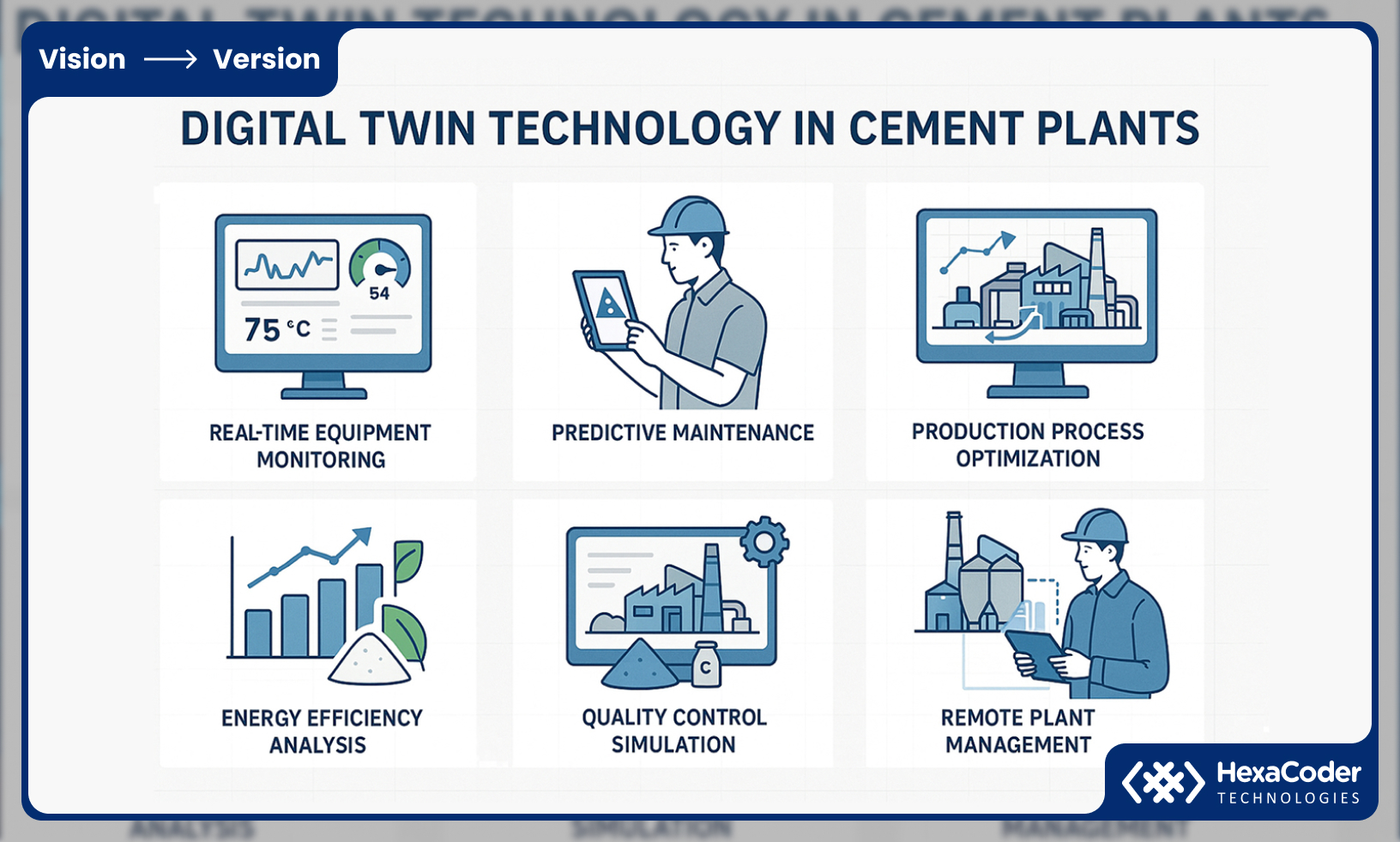

Understanding Digital Twin Technology in Cement Manufacturing

To put it bluntly, a digital twin is neither a figment of the imagination nor something for people to write alarmist biographies about during board meetings. It is a living counterpart of your cement plants, not a representation on a piece of paper, nor an academic exercise, but a virtual environment that simulates actual conditions. Imagine it as a second clone plant that is simultaneously operational, only this one is on a screen and is continuously drawing real-time data from sensors, machines, and processes at your physical locations.

Such a scenario is highly beneficial for an industry like cement production. Instead of waiting for a breakdown or inefficiency to occur, plant operators are able to forecast them. Instead of relying on the costly guess work of trial-and-error to resolve issues with kilns, crushers, or mills, engineers have the ability to experiment within the digital model. Rather than managing the dozens of disparate silo systems, thinking quality control over here and energy maintenance over there, the digital twin system combines it all into a single system.

It is practical. The Digital twin telescopes a mostly unidirectional recessive process and fractures the cement industry into an ecosystem of forethought. This is accomplished through the introduction of digital twin technology, advanced process simulation and predictive analytics, and the deployment of sensors through the industrial IoT.

In summary, there are no systems or processes that remain operational until a problem occurs. A digital twin gives operators x-ray vision and the ability to perform risk assessments to optimize output without physical waiting.

Key Challenges in Scaling Cement Production

Scaling cement production is not as simple as buying bigger kilns or adding much rocks to a supply chain. The industry has challenges that are defeated which makes expansion really expensive and difficult.

Without addressing these, any attempts to scale risk running into roadblocks. Some of the challenges are:

Equipment Strain and Downtime

Kilns, mills. And crushers in a cement plant and not built to be pushed endlessly. Ramp op production too quickly and wear and tear accelerates. On plant downtime can easily erase the gains of higher outputs.

Power Use

Cement making is famously heavy on fuel and electricity, with energy bills swallowing a big chunk of the operating budget. As plants try to grow output, waste in energy use only gets worse, making it tougher to strike the balance between being profitable and staying sustainable.

Production Roadblocks

A plant is only as reliable as its weakest link. You might fine tune raw material grinding, yet still run into trouble at the clinker cooler. Growth calls for a full picture view, something old style monitoring systems often fail to give.

Steady Quality

In cement, quality is non negotiable. Even tiny slip ups in mixing or burning can show up later as structural cracks or failures. The bigger the scale, the harder it is to keep the same level of quality steady across every line.

Green Demands

With regulators tightening emission rules and communities calling for cleaner operations, expanding production while cutting carbon output is a balancing act no plant can ignore.

With regulators tightening emission rules and communities calling for cleaner operations, expanding production while cutting carbon output is a balancing act no plant can ignore.

Team Preparedness

New machines and processes demand new skills. Without proper training, expansion risks creating gaps in know how that can slow things down or lead to costly mistakes.

Growing is not just limited to adding capacity. It is about being efficient, sustainable, and resilient. That is exactly where digital twin technology steps in. It flips obstacles into opportunities.

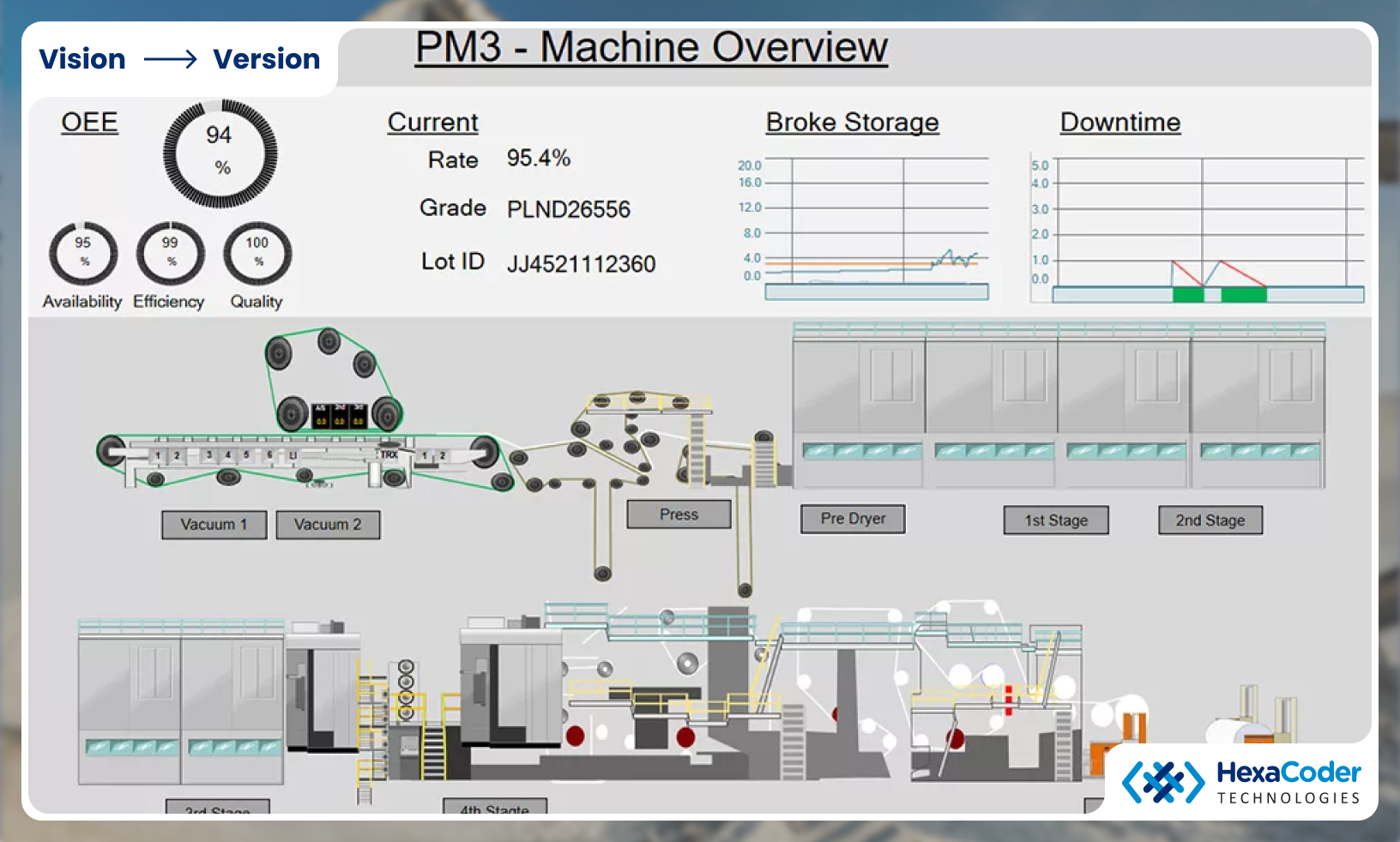

Practical Applications in Cement Plants

Digital twins are no longer concepts solely reserved for innovation slides. They have started to change how cement plants function. The impacts are felt most with the kiln which needs the most energy and is the most vital part of production. By simulating the distribution of heat, fuel, and airflow, digital twins provide operators with insights on how the kiln operates at different conditions. This ease of visibility enables operators to adjust their settings in a way that optimizes clinker production without increased fuel expenditures and equipment stress.

Another area which is gaining much from technology is grinding. Cement mills are sets of machines where any change to a system can drastically alter the outcome. With a digital twin, these parameters can be sustained and controlled extremely well leading to more efficient cement mills production and reduced stress on the machines.

When scaling production, it is very important to have a high level of consistency in the preparation of the raw mix. With digital twins and modeling the processes in real time, plants are able to have a low variation baseline chemical composition while producing high quantities.

This stability easily results in smoother operations and more predictable performances across the production line.

Digital twinning adoption facilitates changed maintenance procedures. Operators move from responding to breakdowns to predicting equipment failures using sensor-driven models. In such a case, the planned interventions are scheduled to cause minimum disruption and keep production running without any unplanned surprises.

Energy efficiency, emission control, and productivity also benefit from growing concerns within the cement sector. Digital twins assist in resource allocation by providing real-time feedback concerning fuel efficiency, carbon dioxide emissions, and the production system to help companies find a sweet spot between production growth and environmental protection. Lastly, the models act as training for the workforce. Without real equipment, the virtual plant system allows new employees to gain confidence and develop their skills to avoid costly mistakes. This improves the transition to higher capacity.

Overall, the practical applications illustrate that digital twins are more than just ethereal concepts. Instead, they are effective frameworks within which cement producers can expand their operations in a safe, efficient, and sustainable manner.

Challenges and Considerations

Though there are several advantages of using ‘digital twins’ in cement production, the process of adoption has some challenges. Implementation costs are, perhaps, the most significant barriers companies have to tackle. Digital twins incorporate sophisticated engines, software, data frameworks, and even infrastructure. For cement manufacturing facilities, the negative profit margins and the exorbitant costs of digital twinning make the initial finances unreasonable. However, the end returns of traditional cement production digitalized with the aforementioned are indeed profitable.

Sensors used in cement manufacturing digital twins with poorly calibrated data constructions will yield defective and erroneous outcomes. Cement manufacturing encompassing mechanical devices and the chemical interaction of constituent cement materials involves complex networks and streams. With regards to constituent and constructing cement manufacturing processes, there are cohesive and non-cohesive data which streams are abundant and limited.

Connecting with pre-constructed systems and soft wares is another challenge. Cement manufacturing facilities are several digital twins behind and in most cases, the agility of control systems were never capable of converging with contemporary software systems. Twinning a digital cement manufacturing plant with traditional ones incurs the technician with the dilemma of balance operation disruption and smooth transition. Falling to procure either shifts the problem from one hand to the other.

Just like the former, the latter is just as vital. It is the duty of the engineers and operators to learn how to utilize crossroads technology to its full potential. Most businesses, including cement production, won’t change their practices unless they see tangible options. But there is considerable inertia. Adoption won’t happen unless workers perceive a value in the tools. This suggests that leadership must segment the digital twin rollouts with cultural transformations that nurture the invention of new tools and methodologies.

Cybersecurity must also be considered. Digital twins require constant data streams, and, therefore, associate with networks that are prone to attacks. Sensitive operational data, when access restricted, must also be protected in situations that can risk production and operational safety.

The adoption of digital twinning in cement production is not going to slow down. There is the growing need for high efficiency, sustainability, and scalable options in the industry. Companies need to have a clear plan of action where any problems are solved before major steps of implementation.

The Road Ahead for Cement Plants

The cement industry has always represented strength and determination. From the bridges that connect cities to the towering edifices that dominate skylines, cement has shouldered the weight of achievement. But as demand grows and landplants face pressures of cost, efficiency, and sustainability, the question is no longer whether Plants should modernize, but rather, how fast they can adapt.

Digital twins no longer belong to the realm of sci-fi. They are practical asset to build cement plants with sharper control over their processes. These are the digital control tethered to each ·ghost" in the plant bottleneck scenario, where bottlenecks become visible before they slow production, breakdown occurs before faults, and energy is fine tuned for optimal cost and emission. These benefits are tangible and cement producers worldwide are starting to enjoy them.

These, making cement is no longer as simple as building bigger, stronger kilns, and adding grinding units. It's the scaling of precision and augmented intelligence. Its the veracity and certainty in scaling production that every subsystem from raw material to final dispatch is gage-optimized to perform efficiently under a load. With every frame wielding, growth becomes structured. It is no longer a gamble.

Implementing technologies like digital twins comes with costs, new training, and a change in perspective. The benefits, however, are unquestionable. A cement plant that is more durable, develops quicker, and is more environmentally friendly. Companies willing to invest at this stage, however, are leaps ahead in usability and overall productivity.

Take the Next Step

If your goal is to expand production capacity, cut costs, and meet rising sustainability demands, digital twins are no longer optional. They are essential.

Ready to explore how digital twins can transform your cement production?

Partner with us to design, implement, and scale a solution tailored to your plant’s needs. Let us turn complexity into clarity and ambition into results. The future of cement manufacturing is here. Make sure you are leading it.