A 3D product configurator system can revolutionize product design, sales, and delivery for your company. One can imagine a reality where your team does not have to address a product with two-dimensional pictures or written descriptions. They can view all your products in three-dimensional form, turn them in all directions, examine each part in detail, and even prototype different versions before a single piece is produced.

Such transparency is a definer in this case it can revolutionize the way decisions are arrived at. Engineers can detect potential assembling problems early on, thus minimizing expensive errors. Product managers can assess product functions in a better manner, thus ensuring they cater to market requirements. The sales and marketing department can display goods in an animated manner to customers, hence instilling confidence in them concerning the goods they purchase. They all share information in a shared platform, hence increasing cohesion and facilitating enhanced decision-making.

A 3D product configurator will therefore enable companies to react better to customer requests. Present-day consumers demand variety and customization. They demand these without any delays. For instance, in industries such as heavy machinery, automobile parts, or consumer electronics, customers will sometimes require distinct product specifications. A product configurator will otherwise make it a challenge for companies to provide accurate quotes or product images in a matter of days or weeks, resulting in a slow sales cycle for companies and consumers. Companies will therefore be in a position to create product specifications instantly and check if they can be produced right away.

A configurator, though, is only good if it is used well. A company can't simply go out and purchase a configurator tool and install their models and think these issues are fixed. A poor strategy, poor-quality information, or a confusing process can make a tool which is very useful end up being frustrating for a team to work with. "Their team can have trouble working with the system, they may have flawed models, or each department can be working in a bubble despite your investment in technology."

The implementation step involves consideration of goals, processes, and work flows. Additionally, implementation may need inputs from different teams, including engineering, product management, sales, marketing, and information technology. Additionally, all stakeholders need to understand the objective of using a configurator. The system must not introduce a new bottleneck.

A 3D product configurator, when deployed in the right manner, can help with product visualization. Rather, it can transform into a strategic tool. A 3D product configurator can aid in increasing efficiency, speeding up time to market, improving customer interaction, and lowering chances of error during production. Organizations deploying these tools in an efficient manner can leverage complexity and make product customization simpler, faster, and error-free than before. Here are 5 Best Practices for Implementing a 3D Product Configurator System

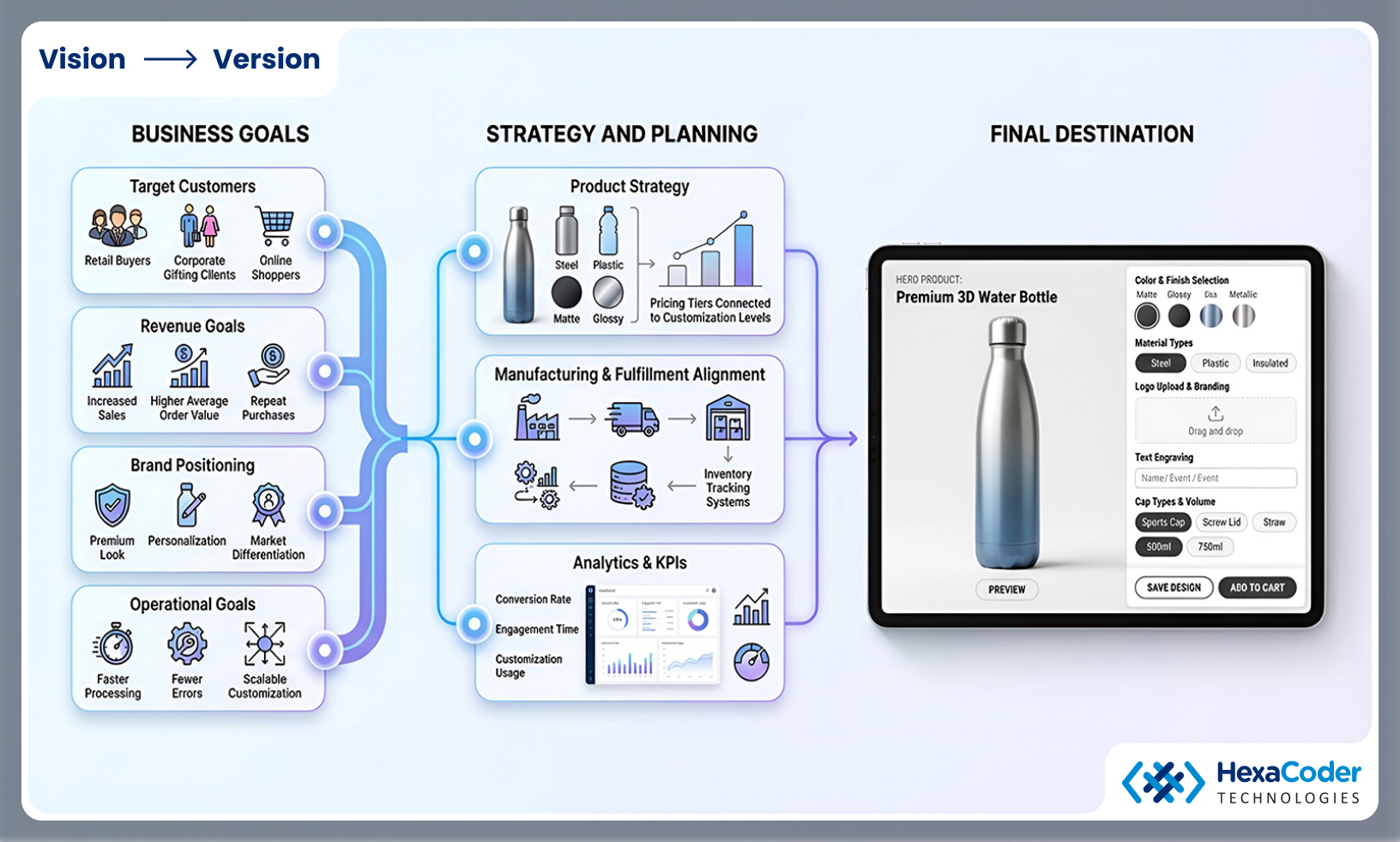

- Set Clear Goals Before Proceeding

A successful implementation begins with setting aims. Without an understanding of what you want to accomplish, a state-of-the-art 3D configurator will not be able to achieve this for you.

To begin with, you need to ask yourself: "What is this system primarily meant for?" Perhaps you want to speed up your product development cycle? Perhaps you want to cut down on design errors? Or perhaps you want to facilitate better customer interaction and sales? Or maybe a combination of all these?

Then, it is necessary to identify stakeholders. Every department, such as engineering, product, sales, marketing, and IT, will have different requirements from this system. While engineers can be concerned with rules of assembly and function testing, product managers would focus on feasibility and workflow. Sales and marketing would need simple visual representations for communications with customers.

Lastly, establish metrics of success. Maybe you’d rather cut your product development time by a fixed percentage. Maybe you want to lower production defects. Perhaps you can improve sales from your configurator tool or speed up your sales cycle. Such metrics enable you to gauge the effectiveness of your system and improve it over time.

A solid understanding of goal concepts and outcomes is indispensable in a successful implementation. Otherwise, a successful outcome is impossible with technology, regardless of how good it may be.

- Begin with a Flexible and Scalable Platform

Platform selection is very important. Your 3D product configurator not only has to fulfill existing requirements but also be able to accommodate future requirements driven by increased complexity.

Flexibility is important. A system which is inflexible and does not work with a change in product design or a different configuration will soon become an obstacle. Your software will need to support added product lines, additional options, and modifications in your designs based on your evolving business.

Integration is equally important. Your configurator tool ought to interface with all your systems, such as enterprise resource planning, product life cycle management solutions, and customer relationship management systems, very easily. Such integration will make sure changes in designs automatically move from engineering to production and then procurement.

Scalability can also be an important factor in your consideration. As you expand your product offerings or your customization requirements become more intricate, your system will have to support such complexities without negatively impacting its speed. Cloud systems will excel in providing you with flexibility and scalability.

Finally, stay away from platforms which have predefined workflows. Your workflows may alter over time, and your configurator needs to undergo transformations accordingly. Therefore, you need to make sure you invest in a platform which is not just adaptive but scaleable too.

- Focus on Data Accuracy and Model Quality

A 3D product configurator can only be effective if the models used are of good quality. Poor models can cause confusion, errors, and wasted time and resources.

Every 3D model ought to be checked for accuracy. The dimensions, tolerance, materials, and assembly requirements ought to be accurate. An inaccuracy in a 3D model can cascade through a system to give incorrect configurations, flawed prototypes, or production errors.

Very accurate models will further boost confidence in the system. Engineers, product managers, and salespeople can be confident in using a configuration tool output to represent a true-world product. Such confidence promotes usage and will make sure it gets used in a uniform manner in an organization.

Moreover, it is essential to keep the models current. Products keep improving, with new varieties being introduced. A current configurator will therefore make sure that it always reflects all product varieties. A system becoming outdated soon will lack credibility and become a bottleneck, thus not a solution.

- Create an Intuitive User Experience

No matter how advanced a configurator is, it will never succeed if it is hard to understand and work with. A simple and friendly interface is a must.

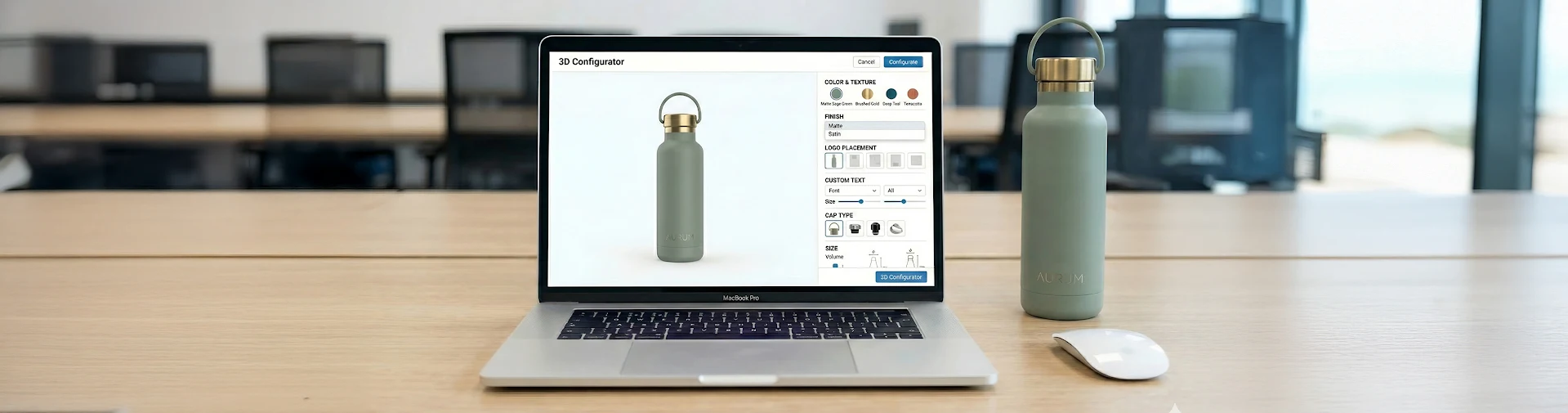

Functions such as rotation, zooming, and dynamic update enable consumers to browse products in a natural way. For complicated products, workflows assist consumers in making selections without errors.

The configurator can be used by a variety of people, including engineers, sales people, and consumers. It is very important to make sure such a system is simple to navigate for all of these people. Confusion in menus, steps, or screens will cause frustration among all these people.

The learning process must be simple yet thorough. Users need to easily grasp basic operations and have available assistance or a manual for learning complex functions of a system. A simple interface leads to participation, error minimization, and full utilization of a system.

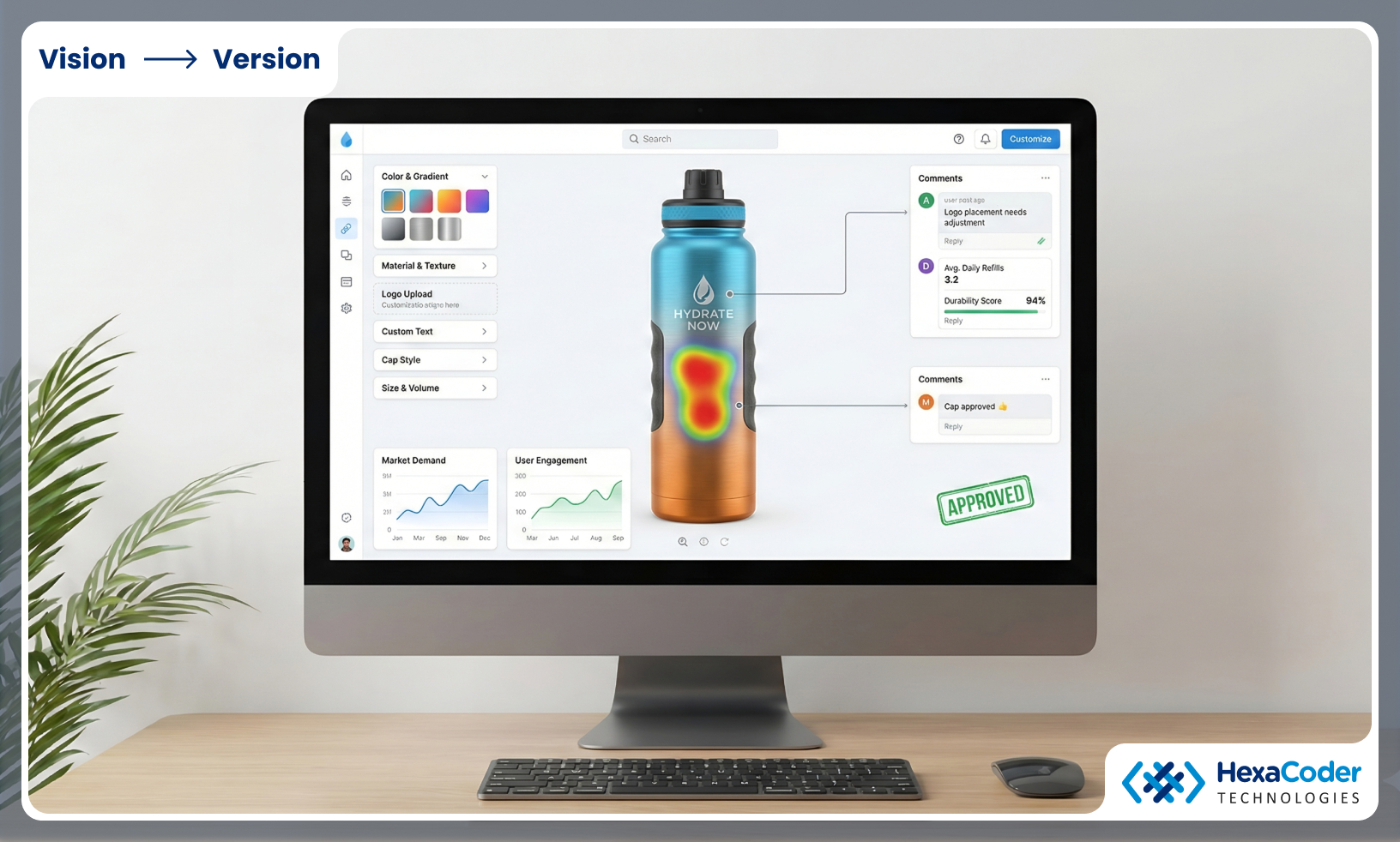

- Planning for Collaboration & Feedback

Application is not a one-time process. For a successful 3D product configurator, teamwork and interaction are an ongoing process.

Bring cross-functional teams on board right from the start. Engineers, product managers, sales, marketing, and support personnel all have different viewpoints on how a system can be used. They can influence how a configurator will be used because all theoretical requirements may not be met.

Feedback and testing are very important. Before widespread implementation, allow teams to test this system, work through pain points, and make suggestions for improvement. Feedback can allow this configurator to better meet expectations.

Continuous Improvement

Continuous improvement is not just important in developing a cloud application but also in improving an existing application. A product will keep evolving in the future, and customer expectations will change over time.

Working together and getting feedback leads to ownership. The more a team feels they have developed the system, the more they will want to use it and trust it.

Reducing Complexity, Creating Opportunity

A 3D product configurator solution is much more than a simple tool because it impacts all realms of product creation right from design, engineering, and right up to sales and interaction with customers. A 3D product configurator solution can bring immense efficiency, eliminate costly mistakes, speed up product launches in the market, and provide product information clarity to stakeholders to make sound decisions.

The effectiveness of a configurator is not in the technology but in its application. Organizations which invest in setting up sound goals, identifying a platform which can scale up and accommodate modification, ensuring sound product models, creating a favourable user interface, or encouraging interfunctional cooperation have a lot to gain from such a system. They will make such a tool an important asset for achieving better results in an organization.

“As products become more and more complex and people demand more and more from them,” a 3D product configurator is no longer a luxury but a requirement. A 3D product configurator is important because it enables an organization to quickly react to market requirements, make less errors before production, and deliver a seamless and interactive experience to customers. The product configurator will be at the center of smart product development because it will allow an organization to transform potential complexity into a competitive advantage,”

Every experience with a configurator testing configurations through to locked and loaded production designsis an experience waiting to be optimized when working with a configurator. The better a company refines this process, the better the payoff in terms of faster design cycles with fewer costly errors, happier customers, and, at the end of it all, better business performance.

Go to the Next Step with Hexacoder Technologies

At Hexacoder Technologies, our area of expertise is in assisting businesses in setting up 3D product configuration systems which work successfully. Our team of professionals possesses in-depth technical knowledge along with industry experience to make sure your configuration system is not just set up but also optimized and in sync with your business.

Whether you are an executive at a manufacturing firm, a product manager, or a technology officer overseeing a digital transformation initiative, Hexacoder is the resource you need to make your 3D configurator an asset for your business. Whether it is setting up a system, deploying a system, model optimization, or workflow integration, Hexacoder is your answer to making a complicated system a seamless one.

Let complexity hold you back. Empower your business by transforming your product development cycle with reduced errors, customer interaction like never before, and so much more. Partner with Hexacoder Technologies today and see how a complete implementation of 3D product configuration can help your business thrive.

Contact exacoder Technologies today and start your path to smarter, faster, and more confident product development.