There has always been a focus on precision when it comes to manufactory production. Right down to the placement of equipment within a manufactory to the timing of operations, small considerations lead to huge consequences. However, many manufactory facilities are operating with disparate information, reporting, and feedback to make manufactory production process-related decisions, when the new reality requires real-time intelligence.Smart Factories are not merely automated. Smart Factories are visible. To know what is happening in machines, processes, and systems at any point in time is what differentiates reactive facilities from the resilient. It is here that the importance of digital twin software becomes paramount. It provides factories with a real-time mirror image of their operations such that facility leaders can look ahead to solve problems and plan.

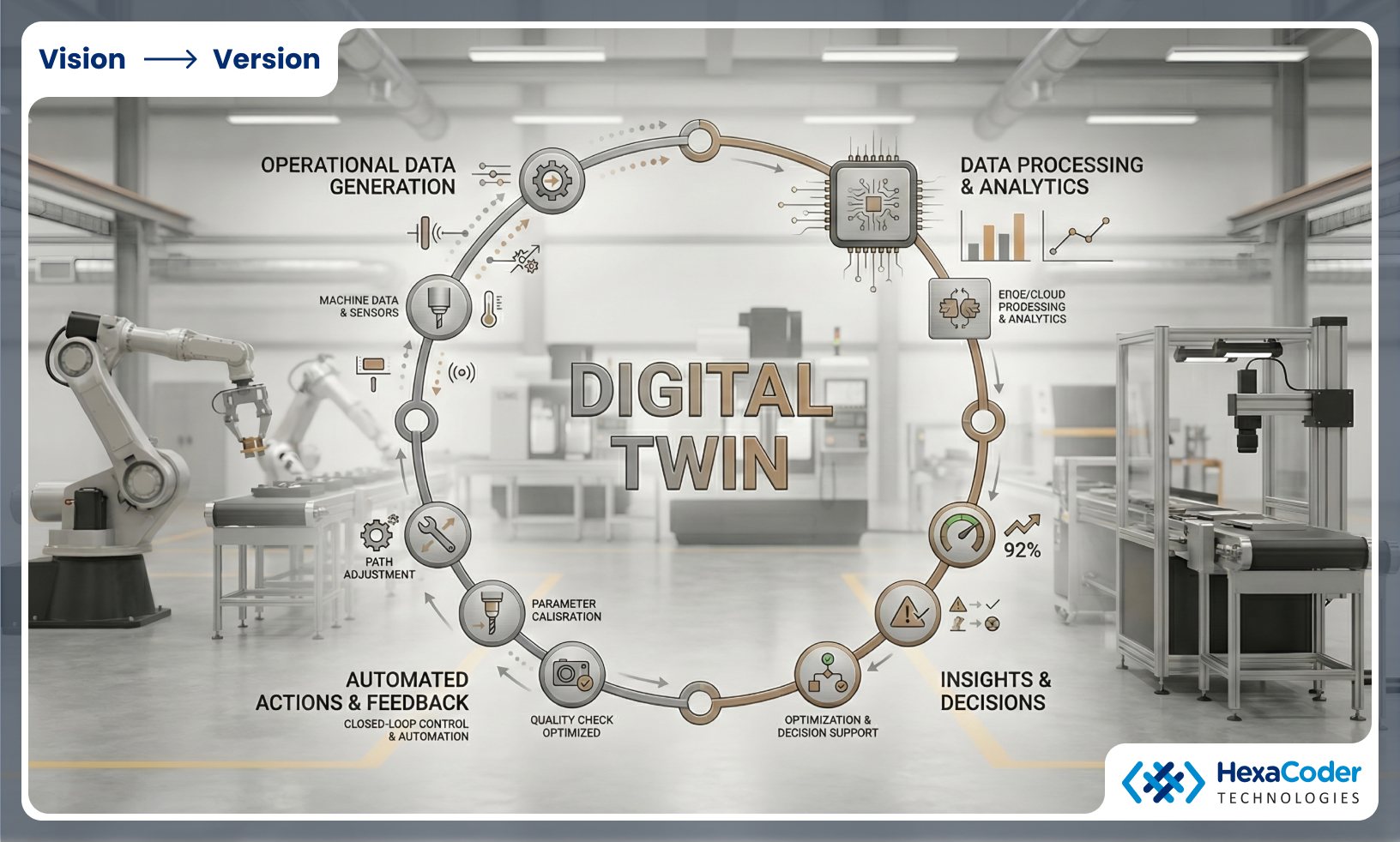

Digital twin software is rapidly emerging as the backbone for smart factory software and even as a fundamental element within Industry 4.0. It links physical assets to virtual models, thereby achieving clarity through complexity and converting unrefined data to meaningful insights.

What Digital Twins May Actually Entail on the Factory Floor

Digital Twin Software can be defined as a virtual replica of a tangible asset. This is just not the case. This software is much more complex than that. Digital Twin Software in a manufacturing setting is a virtual representation of manufacturing equipment, production lines, processes, and even plants that are linked with real-time data. Unlike simulation models, a factory twin reacts to changing conditions with the passing of time. When a machine is running slowly, the twin indicates it. If the twin detects unusual vibrations with the help of the sensor, it indicates the same. If the production level goes up, the twin shows the effect of it.

The living link between the physical world of machinery, material, and energy, and the world of ones, zeros, and bits enables factories to know not only what is occurring, but also why it is occurring, and what is likely to happen next. It is this difference between knowing and understanding that gives such significance to the role of industrial digital twins.

Digital Twin Technology in Smart Factories

The application of digital twin technology in smart factories uses The smart factory is founded on networked systems. Machines talk to sensors, and soft platforms relay information, while teams rely on reliable information for quick decision-making. The digital twin technology is thus the layer harnessing this integration.

Instead, machine data is considered within the factory environment in relation to all other machine data. Factory teams see it all from one perspective. Production managers monitor throughput. Maintenance managers monitor equipment status. Automation engineers test without impacting active lines. This enables machine data to be considered within the factory environment.

It eliminates any potential alignment differences between units. The common understanding fosters coordination, as all employees share one source of the truth rather than working on a variety based on different data sets or interpretations.

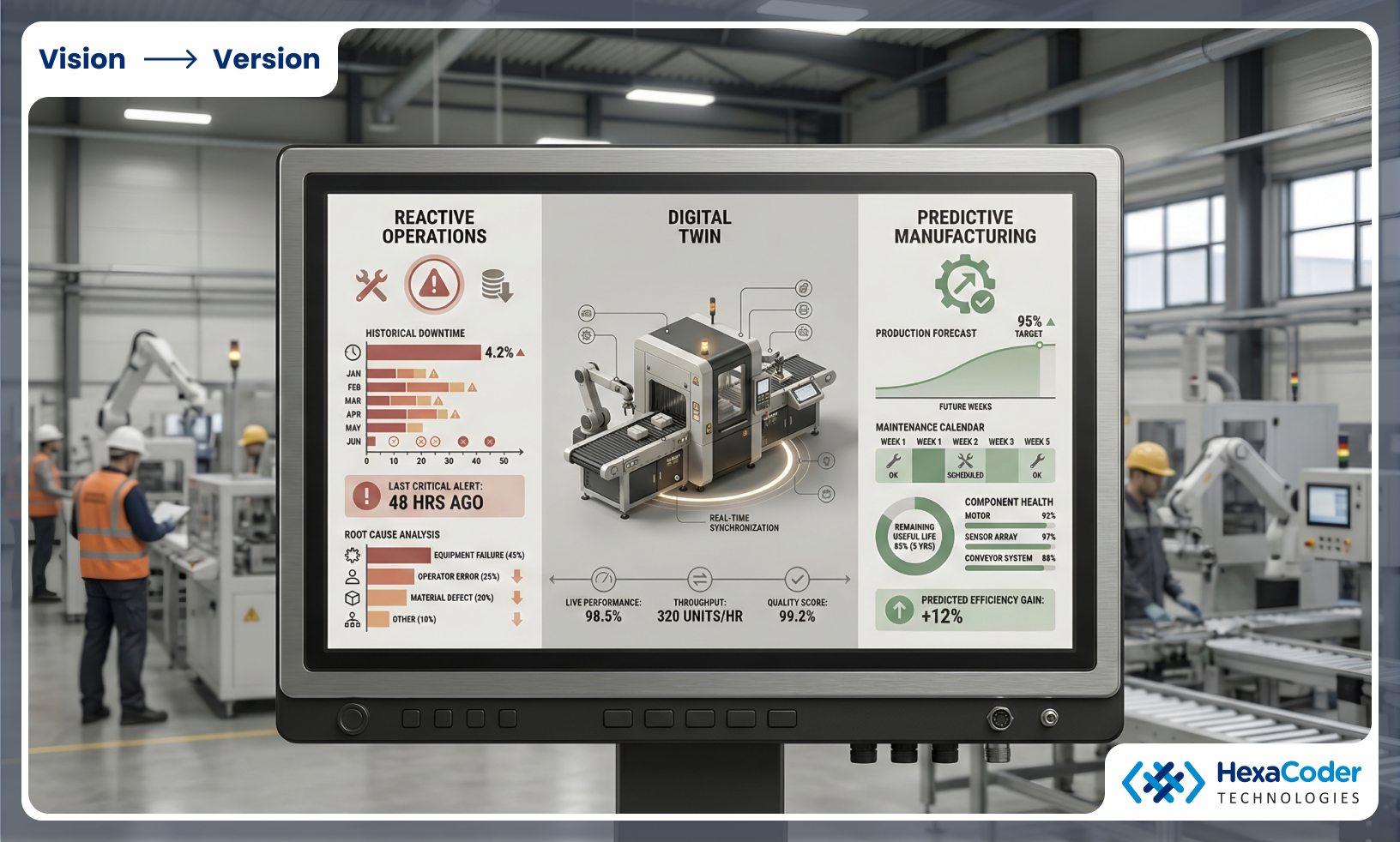

Reactive Operations to Predictive Manufacturing

The classic factory management usually deals with challenges that have already arisen. Equipment malfunctions; production ceases. Then teams activate to resolve the situation. The software introduced by the digital twin alters that.By continuously analyzing the operating data, the digital twin looks for patterns of potential problems before the failure actually occurs. Variations in temperature, vibration, energy usage, or cycle counts may indicate inefficiencies or wear well before the actual failure occurs.

This enables predictive maintenance, which in turn means that the maintenance that needs to be done has to be carried out at the best possible time, which in turn reduces downtime. Additionally, this helps in optimizing parts replacements, which in turn reduces costs in the end as the life of key assets in factories increases.

Improving Production Planning and Process Optimization

In traditional factories, production planning rarely follows a smooth path. External factors may suddenly upset planned schedules. Digital twin software provides planners with the facility of testing scenarios before taking any action.A digital twin for the factory can model capacity, layout change, or sequences of processes, allowing it to demonstrate these effects. A manager no longer has to make estimates but instead sees the outcome.

This is particularly important in a smart manufacturing shop floor, where flexibility and speed are key factors. A factory would be able to respond better to changes in the marketplace, introduce better variants, and avoid planning mistakes.

Supporting Automation and Industry 4.0 Initiatives

Industry 4.0 is no longer about putting machines in place and then waiting for the outcome. Industry 4.0 is all about establishing smart systems that learn, adapt, and evolve with time. Digital twin software is an essential part of this process.

Automation engineers use digital twins to check control logic, test automated action sequences, and optimize processes beforehand. This decreases the commissioning effort and prevents errors in the commissioning process.

As more and more factories implement robotics, sensors, and networked machines, digital twins play a significant role in ensuring that these different systems function together in a desired way, thus providing a stable, efficient, and scalable smart factory ecosystem.

Data Integration and Single Source of Truth

Factories create massive amounts of data, and data does not automatically equal insight. Digital Twin software pulls together data from various systems such as manufacturing execution systems, enterprise resource planning software, and machine controls.This integration helps to remove the problem of data silos and the process of data matching, as in the past, data used to be exported in the form of spreadsheets or in the shape of reports, and then accessed. Factory owners and consultants will benefit from this level of transparency since they can rely on this clarity to make stronger planning and investment judgments in terms of justifying upgrade investments and/or process changes or capacity additions.

Creating Value in the Real World for Factory Stakeholders

Factory owners have the benefit of digital twin software, which helps them see performance, risk, and ROI. It also tells them how their resources are being used and where they need to improve. It provides control for plant managers. They are able to detect bottlenecks in their operations by using this method.For the automation engineer, the digital twin means less trial and error. Simulations of the system can be carried out virtually. This saves time and eliminates any interruptions. Digital twin technology gives Industry 4.0 consultants the tools they need in order to provide real transformation, not just ideas. Regardless of the role, the benefit in each case will remain the same. Informed decision-making, reduced risk, and rapid learning will become

Scaling Digital Twin Software Across the Factory

One area where current digital twin software excels is in scalability. In today’s scenario, it is not necessary to model everything in one go in a factory’s digital twin. Many operations start small, beginning from a single machine, production line, or process.The more confidence that is gained, the more the digital twin is populated with further assets and activities and even further detail on functional performance.

With time, the digital twin becomes a strategic resource, no longer viewed from a technological perspective. It helps with operational matters, while also informing long-term strategies for improvement.

Importance of Digital Twin Software in Smart Factories

Smart factories require understanding, speed, and adaptability in a world where complexity escalates each year. This is where digital twin software excels, as it offers all three qualities in a world where complexity increases annually. A digital twin software system is more than a simple data collection mechanism. Instead, it helps to add interpretation to data, perspective to performance, and purpose to decision-making. Some reasons why digital twin software has become so important in smart factories follow:

- It Creates a Single, Clear View of Operations

The data created by the machines, sensors, systems, and humans in factories has to be massive in nature. If this data is not organized, it can remain disintegrated in nature. The digital twin technology has an ability to integrate all the data in one form to provide a complete view of the factories. Instead of monitoring the data in disconnected dashboards and reports, there is an opportunity to view the machines, processes, and workflows happening in real time.

- It Replaces Guesswork with Informed Decision Making

Many of the choices in the manufacturing process are still made through experience. However, in very automated and interlinked settings, experience by itself does not suffice. Digital twin software enables the evaluation of a decision before implementing it in the real-world setting. Modifications related to the production schedule, the equipment configuration, or the change in plant layout can also be evaluated in a virtual setting to know the results of such modifications. Such approaches assist leaders in being confident about the decisions they are making.

- It Facilitates Quicker Reaction to Change

Speed is an enabling factor of smart manufacturing. Market demands change in no time, and supply chain disruptions can happen anytime, while production problems can worsen in a matter of minutes. Faster response is made possible by the digital twin software, which provides immediate insights into what is happening and why. Performance degradation or abnormalities trigger the ability to go back to the source of the problem and address it before it impacts the output or quality.

- It supports predictive and preventive maintenance.

Unexpected downtime has been a source of huge costs for many manufacturers. However, digital twin technology allows predictive maintenance to occur as the system continuously monitors system behavior, ensuring that patterns that call for repairs are identified. This eliminates the need to wait for equipment failure because, at that time, maintenance personnel can undertake the work at the optimal time. This has the effect of ensuring that downtime, as well as the cost of maintenance, decreases.

- It Enhances Collaboration Among Teams

Smart factories function because all disciplines, such as engineering, operations, maintenance, and management, work together. Digital twins offer a common point of reference that synchronizes these groups. Even though everyone uses the same model, they all have the same information, and everyone understands how their plans impact others. If everyone is coordinated, changes happen easier, and everything flows better in a factory.

- It Forms the Backbone of Industry 4.0 Strategies

Industry 4.0 is based on connectivity, automation, and intelligence. Digital twin software integrates these. It links physical resources to virtual systems, enables optimization of automation tests, and offers the analysis required for improvement. Instead of breaking down the digital transformation strategy into a set of disparate projects, manufacturers can now use the digital twin as the hub of the strategy supporting growth.

- It Provides a Sustainable Competitive Advantage

Increasingly competitive manufacturing environments mean that the capacity to make do with insight rather than with insight postponed will be what sets a business apart. Manufacturing enterprises that adopt the concept of digital twins will be in a position to respond and optimize with greater speed and accuracy. Of greater significance will be their preparedness to cater to future requirements of either customization, quality, or automation. Digital twins are now no longer in the testing phase. Digital twins are becoming the norm in smart factory software.

In short, digital twin software provides the insight, intelligence, and control necessary for smart factories to be efficient and effective within this ever more complex environment. Those factories that adopt this technology can move ahead with confidence; those that do not may be left behind within this environment where speed, accuracy, and informed action are rewarded.

Role of Hexacoder Technologies in Smart Factory Transformation

Hexacoder Technologies develops the digital twin technology which is designed to work in real factory conditions. The company’s products concentrate on the accuracy and usability of the digital twin in order to replicate real conditions in the factory and not perfect simulations.The company Hexacoder enables factories to integrate machines, processes, and systems into a logical digital model that can aid in day-to-day operations as well as long-term strategies. The company’s focus on simplicity rather than complexity has enabled digital twin technology to reach engineers, managers, and executives.

For organizations that are on the journey to adopt smart manufacturing digital twin solutions, the solutions offered by Hexacoder are a step in the right direction.

Moving Forward with Confidence

Smart factories are not an overnight creation and are almost never an outcome of an informed decision on any technology alone. Smart factories are what emerge from an ongoing process of informed decision-making and an enablement layer of digitization that facilitates and does not hinder growth. The digitization of smart factory software achieves this enablement layer through improvements brought about in operations and an enablement that supports the shift from reactive to intentional decision-making. Digital twins enable a comprehensive and intelligent understanding of factory operations by creating a holistic overview of the situation. Digital twins allow teams to gain insights beyond the surface level of information. Factory performance, machine status, process flow, and limitations are no longer treated as a set of separate numbers but are provided in the context of the situation. It enables teams to make decisions to optimize performance and manage operational risk.

Factory owners can also benefit from improved management and returns on their investments. They will be able to see transparency in the usage of their assets, the efficiency gaps that exist, and the adjustments that offer the most benefit. For the plant managers, the software available in the industry can be their day-to-day decision aid, assisting them in managing their schedules and avoiding downtime. Meanwhile, the automation engineers can be working in a safe environment to validate their ideas and improve their systems without shutting down their operations. Consultants within Industry 4.0 can employ accurate and linked data to inform their strategies for delivering benefits within the field rather than mere benefits in theoretical approaches.

Complexity will only continue to escalate as manufacturing technology develops. There will be more product variations, changes to the supply chain, as well as growing consumer demands. In such a setting, subpar systems and/or traditional, human-driven methods will become a weakness. Digital twin solutions will ensure that the factory has the abilities required to adapt, grow, and compete.The challenge for the leadership of the world of manufacturing is no longer whether a software solution like a digital twin is needed. That imperative has already been established by the speed of this industry, for example, whereby the need for the software has already been established. The question is now how quickly this solution can be achieved for the long-term benefits that it will offer.