Introduction

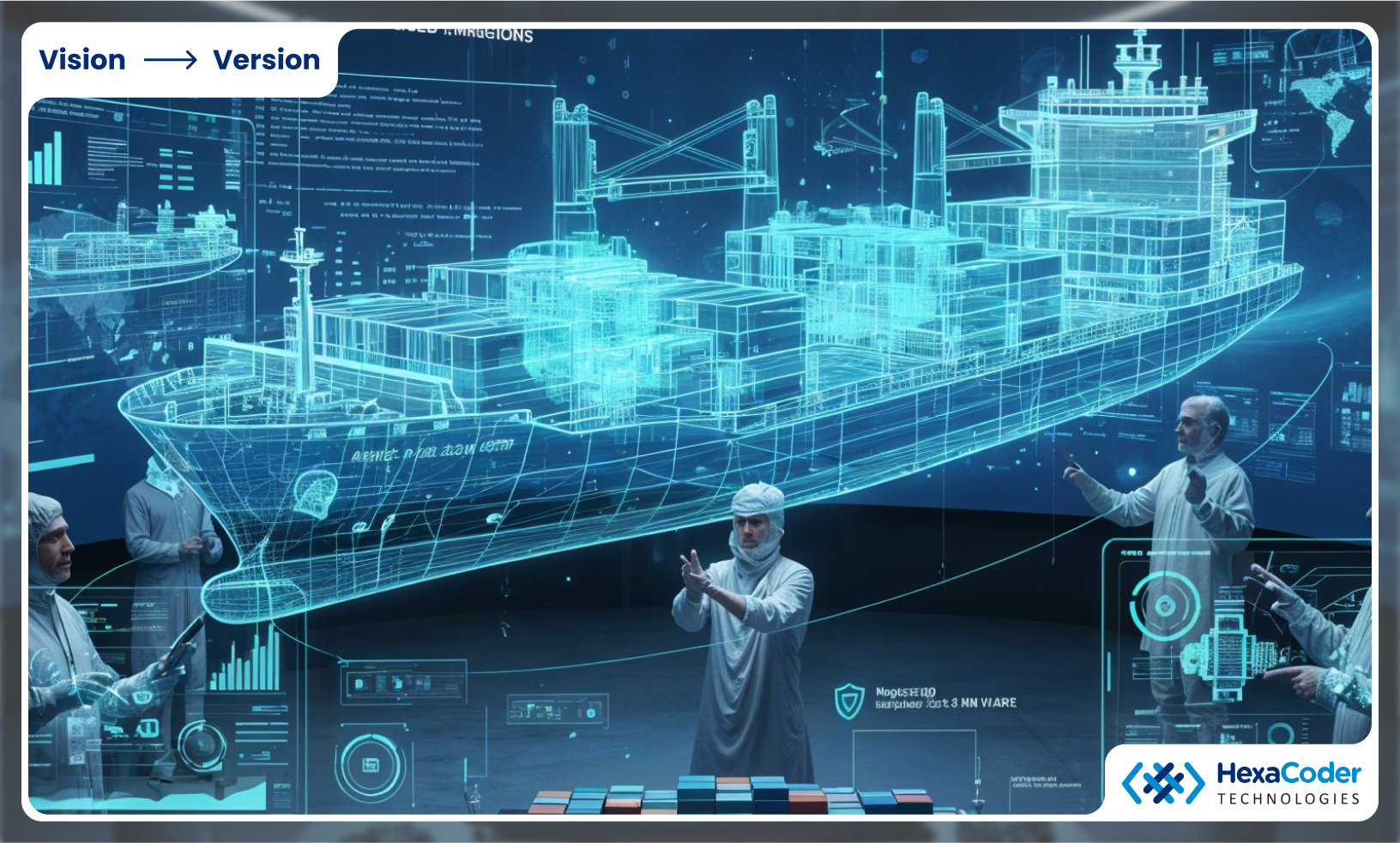

Ships have always changed to be time. They move from old wooden boots powered by wind to the huge container ships we see today, the maritime world has never stopped improving. Now, a new change is happening and this is not just taking place in the shipyard but in the digital space. At the center of this change is something called a digital twin.

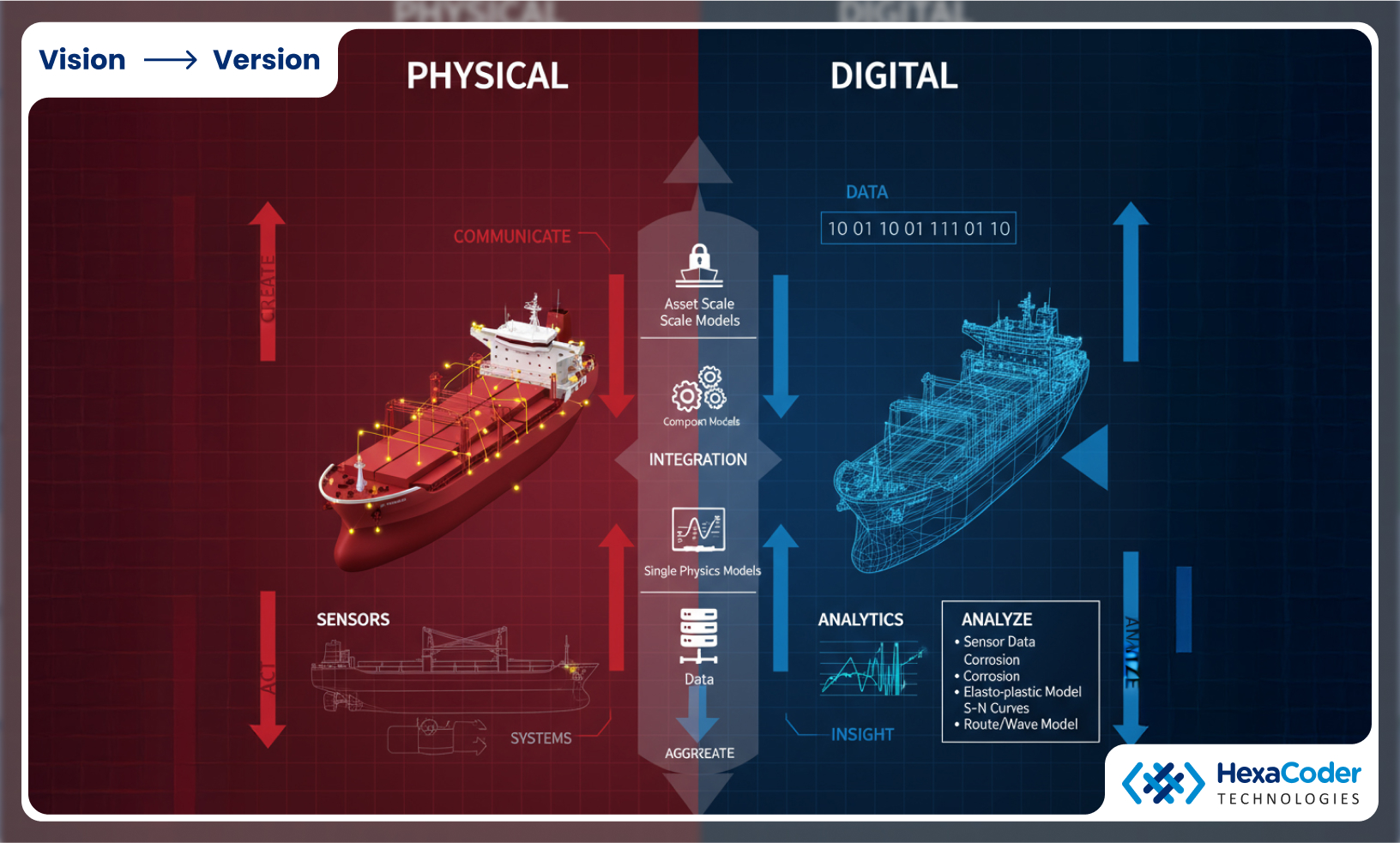

A digital twin is not just a three-dimensional picture of a ship. Rather, it is a life copy that shows how the ship is working every time. With the help of smart sensors, data tools, and cloud systems, a digital twin allows ship owners and operators to see a clear version of everything that is happening on board. It can show how the engine is running, how much fuel is used and how the ship will react to different conditions before any problem comes up.

This is very important because the shipping industry faces many difficulties today. Expenses arising, rules on pollution are becoming very strict and safety at sea is always a concern. The old way of watching and repairing ships is no longer enough.

In this article, we will look at how digital twins can improve shift performance, prevent breakdowns, keep people safe and support sustainability in the maritime industry.

What is a digital twin in the maritime industry

It starts with a virtual example and copy of a real ship. It is created with the use of information that is gathered from sensors placed in different parts of the vessel. These centers watch out if the ship is working in reality. The information is then sent to a computer system that builds a life model of the ship. This life model is not just a picture, it acts like a mirror that shows what is happening inside the vessel at every time. For example, it can display the condition of the engine, the speed of the propeller, or the balance of the cargo. If something wants to go wrong, the system can decrease early so they can fix the issue before it becomes very serious.

In the past, ship monitoring depended on manual checks, crew reports and planned inspections. While all these methods helped, they failed most times to notice problems quickly. But with a digital twin, operators can see small changes immediately it occurs. This means there are better choices made, less breakdowns and safe trips.

Digital twins also allow shipping companies to test different conditions before they happen. They can run a storm test, try new fuel plans, or study how the ship reacts under heavy load. All of this mix the ship stronger, safe and more efficient.

Why did maritime industry needs digital twins

The Mario World industries are one of the oldest and most important parts of global trade. Ships carry most of the goats that move across the world, yet running them has never been easy. Owners and operators face so many difficulties everyday from high fuel cost to strict safety rules and unpredictable weather. These challenges make it hard to keep ships profitable, safe and friendly to the environment.

One of the major issue is the rising price of fuel. Ships need large amount of fuel to cross oceans, and even a small waste in fuel use can cause big losses. Another concern is pollution. Shipping is responsible for a large share of greenhouse gas emissions, and global regulators are now setting tougher limit on a mission. Companies that fail to meet these rules face every charges and loss of reputation.

Safety is another reason why the industry needs digital twins. Accidents at sea can damage ships, destroy cargo and even put human lives at risk. Traditional ways of checking ship conditions are very slow to stop such events. A digital twin can easily see warning signs which makes it easy to prevent accidents.

Fleet management is also a major difficulty. Many shipping companies run dozens or even hundreds of vessels. Keeping track of all of them is very difficult. A digital twin system makes it possible to see the state of every shipping reality which helps managers to work fast and make better choices.

For all these reasons, digital twins are becoming very important because they reduce expenses, improve safety and support the global push for clean and more sustainable shipping.

Enhancing shipping performance with digital twin

The performance of a ship is one of the most important parts of a maritime work. A ship that performs well saves fuel, lowers emission, and delivers goods on time. Digital twins now play a central role in making ships perform better at sea.

One way digital twins improve performance is through fuel use. Fuel is one of the biggest expenses in shipping. Even small changes in speed, engine settings or routes can affect how much fuel a ship burns. With a digital twin, operators can watch fuel used in reality and test different options before making a decision. For example, they can see how slowing down a little or changing the route can save fuel without causing delay. This is not only reduces expenses but also reduces pollution.

Another benefit is vessel efficiency. A digital twin shoes how every part of a ship works together. It can put out where energy is wasted or where equipment is under stress. By fixing these weak points, the ship can run smoothly and with less damage to its parts.

Digital twins also help with planning. Before a ship begins it's truly, operators can run test on the twin to predict how it will perform under different conditions happening on the sea. They could try out rough waves, heavy winds or different cargo weight and see the likely results. This helps screw to prepare better and also avoid surprises during the journey.

Some shipping companies already used digital twins in this way. They have saved money on fuel and kept the ship's equipment in good condition for a long period of time. Overtime, this leads to strong fleet, a better schedule and more reliable services for customers.

Digital twin stone information into actions as they also give operators the tools to make choices that boost performance, reduces cost and keep vessels at their best.

Predictive maintenance and operational efficiency

One of the greatest strengths of a digital twin is its role in predictive maintenance. In the past, most ships reliant on scheduled checks and repairs after something had already gone wrong. This approach most times lead to wasted time, more expenses and sudden breakdowns during long trips. Predictive maintenance changes Days by using live data to find problems before they become very serious.

A digital twin collects information from sensors placed on engines, pumps, propellers, and other parts of the ship. This information goes into the life model which can show small changes on our equipment is working. For example, if a pump begins to make unusual movement or if the engine temperature rises slightly, the twin can warn the crew.

This early notice allowed repairs or parts changes to be done before the major failure take place.

The result is less downtime and few surprises. Ships can stay on schedule instead of being displayed at port for repair. Expenses are also lowered since more issues are easier and cheap yo handle than complete breakdowns.

Operational efficiency is another key benefit of digital twins. By following how each system is running, operators can plan better fuel use, import cargo handling, and arrange port arrivals smoothly. This insight helps whole fleets work together, not just a single ship.

Testing platforms also support this process. Before a ship enter stuff conditions, operators can try out different situations using the twin. They can see how the vessel will react to every cargo or strong waves and plant the safest and most efficient response.

Together, predictive maintenance and high efficiency helps the shil to stay longer, give crew more assurance and saves companies both time and money. Digital twins turn maintenance into a forward looking process which gives maritime industry more control than ever.

Case studies and Real life uses of digital twin in shipping

Digital twin systems are already in use in the shipping world. The following are some real examples:

It utilizes digital twins for monitoring fuel consumption, analyzing engine condition, and route plotting and planning.

Savings on fuel and reduced carbon emissions wasted.

Gained significant savings by transforming actual vessel data into digital.

Develop the star twin for sheep engines and marine systems.

Instruct operators to evaluate engine performance in various conditions.

Avoid failures and reduce maintenance costs.

Implement digital twins on offshore structures and big tankers.

Registers equipment activity without exposing personnel to danger zones.

Increases the safety of personnel and the safety of seamless operations.

Other smaller shipping operators

Implement basic digital twins for monitoring the position of the cargo.

Transport sensitive cargo such as food and medicines while keeping the temperature at desired levels.

Decreased spoilage and increased customer loyalty.

Training Use

Cruise ship personnel practice on digital ship models before actual voyages.

Engineers learn how to manage alarms, settings, and issues on digital engines.

Minimized errors while gaining confidence in the ship’s crew.

Military sector

Navies integrated the use of digital technology for planning and drilling exercises.

Simulate any fire, battle damage, or equipment failures.

Encourage crew to act swiftly and help to preserve lives.

All these use cases approve that digital twin technology isn’t an abstract concept or an imaginary approach, rather it exists and exerts tremendous savings while lowering danger and enhancing vessel operational efficiency.

These examples show how digital twin technology is not just an idea and that it works in real life by saving money, cutting risk and improving ship operations.

Future Outlook for Digital Twins in Shipping

The future of digital twin technology in shipping looks bright. The maritime industry is under pressure from new international rules, rising fuel costs, and the need for safer and more efficient operations. In this setting, digital twins are expected to play an even larger role.

In the beginning, only big companies could afford to use digital twin systems. That is now changing as the technology becomes less costly and easier to set up. Smaller operators will also be able to adopt it, and over time, digital twins will become a normal part of shipping rather than a tool limited to a few large firms.

Another important step forward will come from the link between digital twins and sensors installed on ships. These sensors will keep sending data around the clock to the digital model, making it a close reflection of what is happening onboard. This will give ship owners a clear and updated picture of vessel health and performance at all times.

Digital twins will also be central to making shipping cleaner. With strong pressure to reduce emissions, operators will use digital twins to test fuel-saving methods and ways to cut carbon output before applying them at sea. This makes the move toward greener shipping more practical and easier to achieve.

The growth of self-sailing vessels is another area where digital twins will be important. As these ships become real, digital twins will allow remote teams to monitor their condition, solve problems quickly, and keep operations running without the need for large crews.

Another benefit will be in meeting global rules. Shipping companies face strict standards for safety and emissions, and digital twins will make it easier to prove they are following these standards. This will save time, reduce penalties, and improve trust in shipping practices. At the same time, the technology will improve worker safety. With more checks done digitally, fewer crew members will need to enter risky areas, and many tests can be carried out virtually before being tried on real equipment.

The maritime industry has often been slow to change, but with growing costs and tighter rules, digital twins are on the way to becoming a regular part of the field. Looking ahead, they will shape the way ships are designed, operated, and managed for years to come.

Moving Shipping Forward with Digital Twin

Digital twin technology is changing how ships are managed. It gives ship owners and operators a live copy of their vessels, making it easier to track performance, plan repairs, cut fuel use, and improve safety. From global companies like Maersk and Shell to smaller operators, real examples already show the strong results of this tool.

The benefits spread across many areas. Digital twins save money by cutting waste, support green shipping by lowering emissions, and protect workers by reducing the need for dangerous checks. They also give crews better training, help ships meet strict global rules, and open the door for self-sailing vessels.

Digital twins are not without hurdles. They need investment, skilled staff, and trust in digital systems. Yet as costs fall and access grows, more shipping companies will begin to see them as a normal part of daily work.

In today’s world, where safety, efficiency, and sustainability matter more than ever, digital twins stand out as one of the most valuable tools for the maritime industry. They are not just a hope for the future but a working solution that will shape how ships are built, managed, and sailed for years ahead.

If you are ready to bring these benefits to your fleet, Hexacoder is here to help. Our digital twin services are designed to boost ship performance, reduce risks, and keep you in line with global standards. Contact us today and let us help you build smarter, safer, and more sustainable shipping operation