How Digital Twins Enable Jet Engine Monitoring

Digital Twins facilitate real-time monitoring of jet engines. The operation of jet engines requires extreme temperatures and high pressure and rotational speed conditions which result in substantial safety hazards and operational disruptions and financial damage from even slight inefficiencies and undetected problems. The field of aviation has entered an era where traditional monitoring systems struggle to cope with the increasing demand for operational capacity and the reduced profit margins and the need for enhanced safety and sustainable practices.

Digital twin technology is revolutionizing how jet engines undergo monitoring and maintenance and performance optimization. Digital twins create a virtual model of each engine which operates in real time to provide ongoing updates about engine health and performance and deterioration. The implementation of digital twins enables aerospace manufacturers and MRO providers and airline operators to move from traditional engine monitoring methods which rely on reactive inspections toward a system of predictive operations based on advanced intelligence and data analysis.

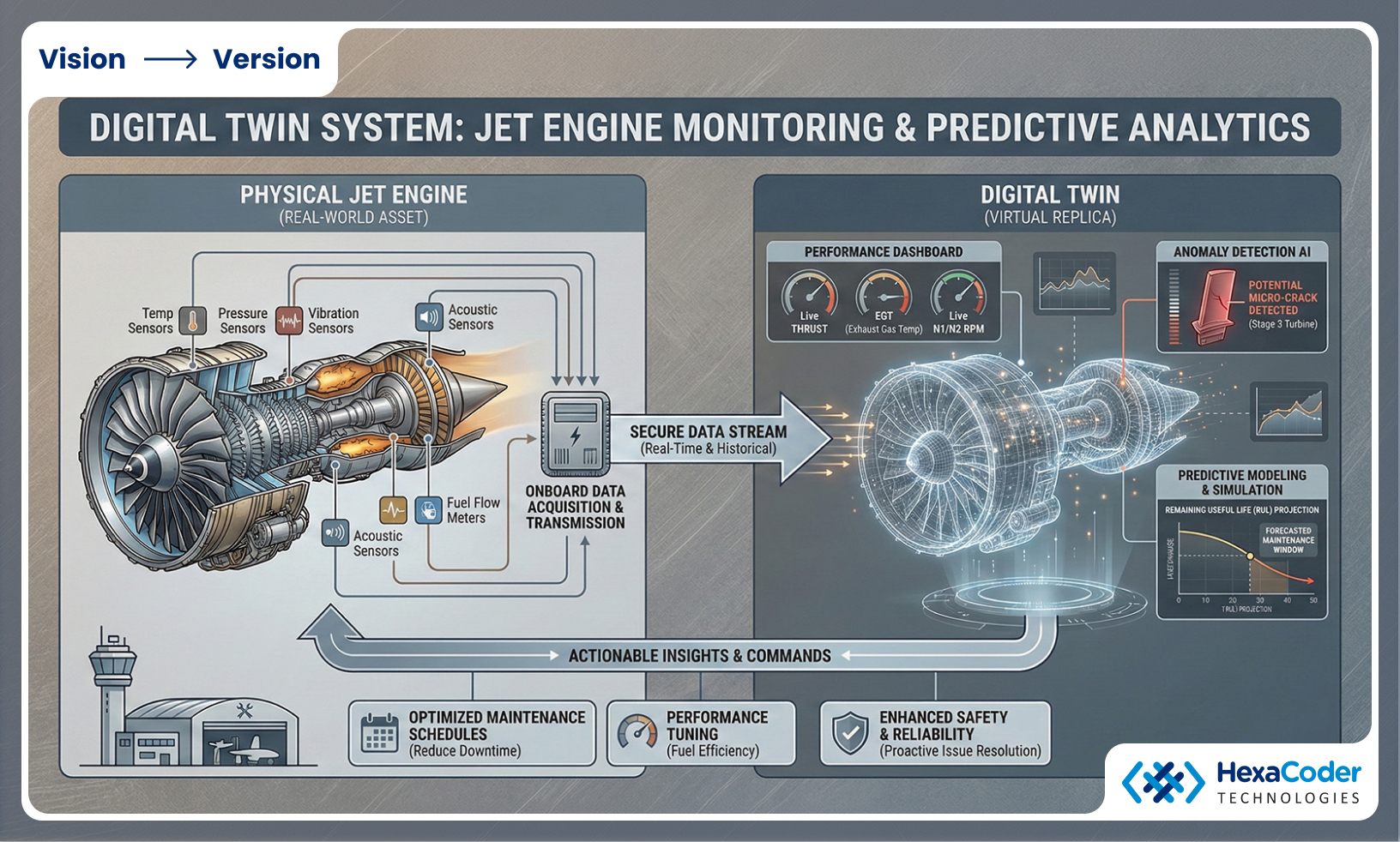

The Digital Twin System Works as a Monitoring Tool for Jet Engines

A digital twin functions as a dynamic digital representation of the physical jet engine which tracks changes during its entire operational lifecycle. The system receives continuous updates from onboard sensors and control systems and the entire operational environment. The digital twin develops throughout engine operation by creating real-time updates of engine wear patterns and performance changes and environmental effects.

Jet engines produce extensive data through their temperature sensors and pressure readings and vibration monitors and fuel flow systems and rotational speed indicators. A digital twin processes this information to create an engineering model which compares to the engine's actual design and material specifications and operational limits.

Digital twins possess their unique strength because they establish connections between actual physical movements and planned engineering achievements. The twin system not only detects changes to parameters but also understands their effects on component stress and efficiency reduction and remaining operational lifespan. The process converts raw telemetry data into usable operational information.

Engine operators use this system to monitor each engine as a separate operational unit instead of combining them into a standard statistical evaluation. The digital twin uses all operational data from an engine to create monitoring capabilities that exceed traditional threshold-based systems.

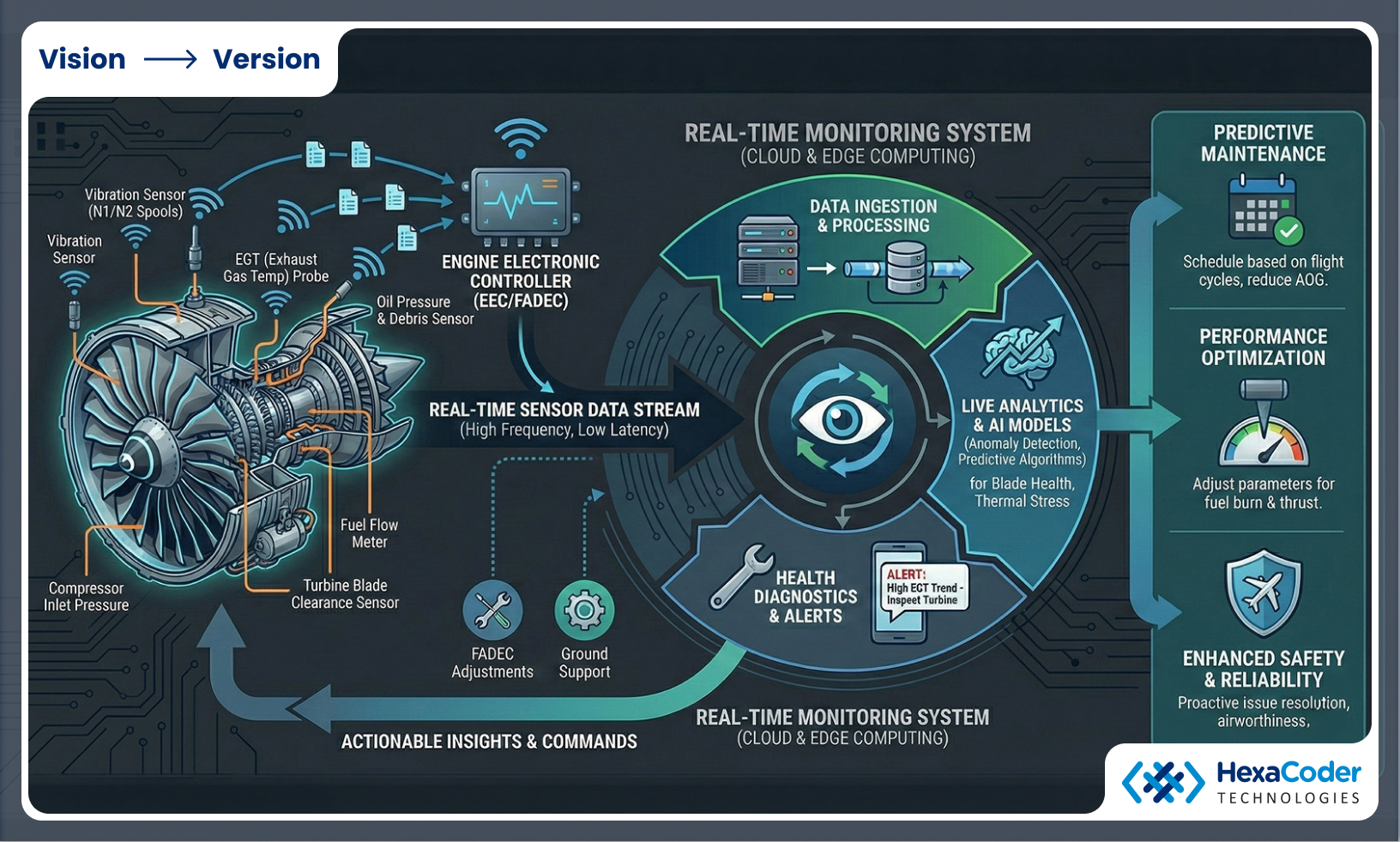

Continuous Engine Health Monitoring Through Real-Time Systems

The conventional method for monitoring jet engines depends on regular inspections and maintenance tasks that follow a predetermined schedule and alert systems that activate at specific points. The basic fault detection methods function effectively to detect faults, yet they struggle to identify initial degradation signs and they neglect to consider how operating conditions and usage patterns affect results.

Digital twins provide nonstop engine health assessments through their built-in engine monitoring system. The system analyzes sensor data stream against the virtual engine model to identify any operational differences that occur. Subtle changes in vibration, temperature gradients, or pressure ratios can be identified long before they cross alarm thresholds.

The system provides operators with real-time access to abnormal engine readings which establish both current engine state and its upcoming state. The gradual rise in exhaust gas temperature may point to either compressor fouling or fuel nozzle issues or initial turbine degradation. The digital twin uses these system signals to establish accurate root cause hypotheses.

The team's situational awareness increases when flight operations and maintenance teams have access to this detailed information. The system provides teams with early warning signals which eliminate the need for them to wait until active alerts and inspection checkpoints signal fault detection. The operational capacity of in-service equipment improves while the overall reliability of engines increases.

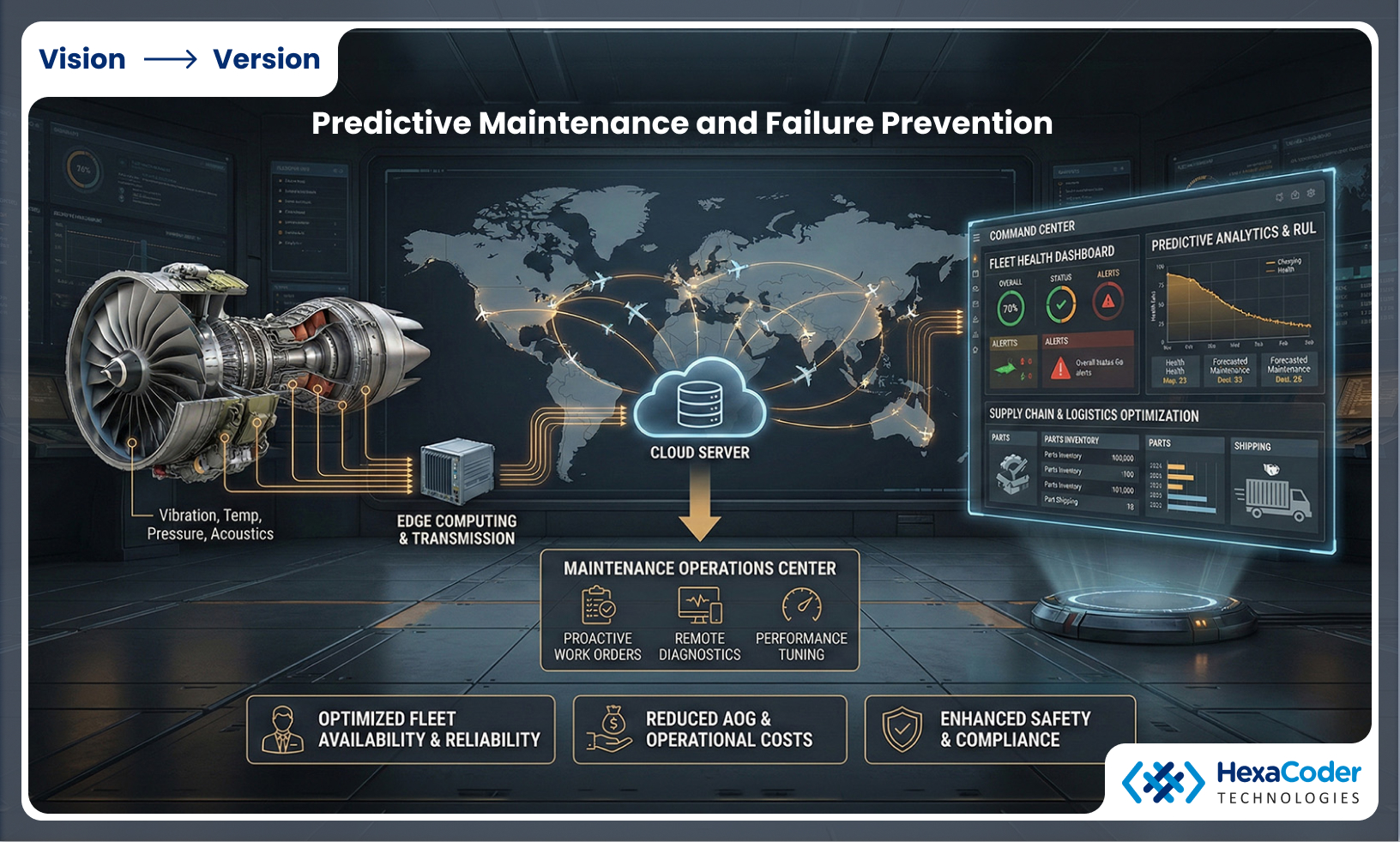

Predictive Maintenance and Failure Prevention

The implementation of digital twins results in predictive maintenance system benefits which stand as the most important advantage for jet engine monitoring. Engine failures do not occur suddenly; instead they follow a pattern of gradual performance decline that remains hidden from standard detection methods.

Digital twin technology performs component analysis which uses both historical data and current real-time information to create degradation models that match actual operating conditions. The twin system calculates the remaining lifespan of critical components through engine current operating conditions.

The system enables maintenance scheduling based on actual engine conditions instead of fixed maintenance schedules. Components will be serviced or replaced only when there is a requirement which leads to a reduction in maintenance tasks while decreasing the chances of in-flight failures and unscheduled removals.

The aviation industry operates under strict safety standards which make failure prevention critical to maintaining safety. Digital twins enable organizations to detect high-risk situations early which allows them to implement corrective measures before problems worsen. The system reduces AOG events while improving operational dispatch reliability and maintenance costs.

Fuel Efficiency and Performance Optimization

The aviation industry considers fuel efficiency to be its most important expense factor because it serves as the foundation for sustainable development programs. The aviation sector experiences significant fuel penalties from even minor jet engine performance changes which occur throughout extended flight operations using multiple aircraft across various routes. The conventional method of performance assessment needs periodical trend studies which can only find inefficiencies after measurable decline has taken place throughout the evaluation period.

The digital twin system enables ongoing engine performance development through its engine monitoring system which assesses actual engine performance throughout its entire operational lifespan. The system evaluates engine performance across different operational conditions which include various altitudes and ambient temperatures and payload sizes and thrust settings and specific flight patterns. The digital twin establishes performance deviation through real-time data comparison with baseline performance models when it detects changes caused by component degradation and fouling and thermal stress and operating conditions that do not meet optimal standards.

Digital twins enable testing of all optimization methods through their secure testing ground which they create for optimization testing purposes. The team can analyze how different changes to control logic and maintenance schedules and operating methods will impact fuel consumption and thrust efficiency before putting these changes into practice on actual equipment. The method moves optimization forward through data-driven decision processes which use predictive analysis instead of reactive tuning.

Airlines and fleet operators experience direct measurable effects through their operations. The business benefits from enhanced fuel efficiency which leads to decreased operational expenses while maintaining profit margins during fuel price fluctuations and decreased carbon emissions without jeopardizing safety or reliability. Digital twins empower engine-specific optimization through their capabilities which enable precise measurement of engine performance throughout its entire operational period. The aviation sector now assesses fuel efficiency as an ongoing outcome which management handles continuously instead of treating it as a measurement which happens at scheduled times.

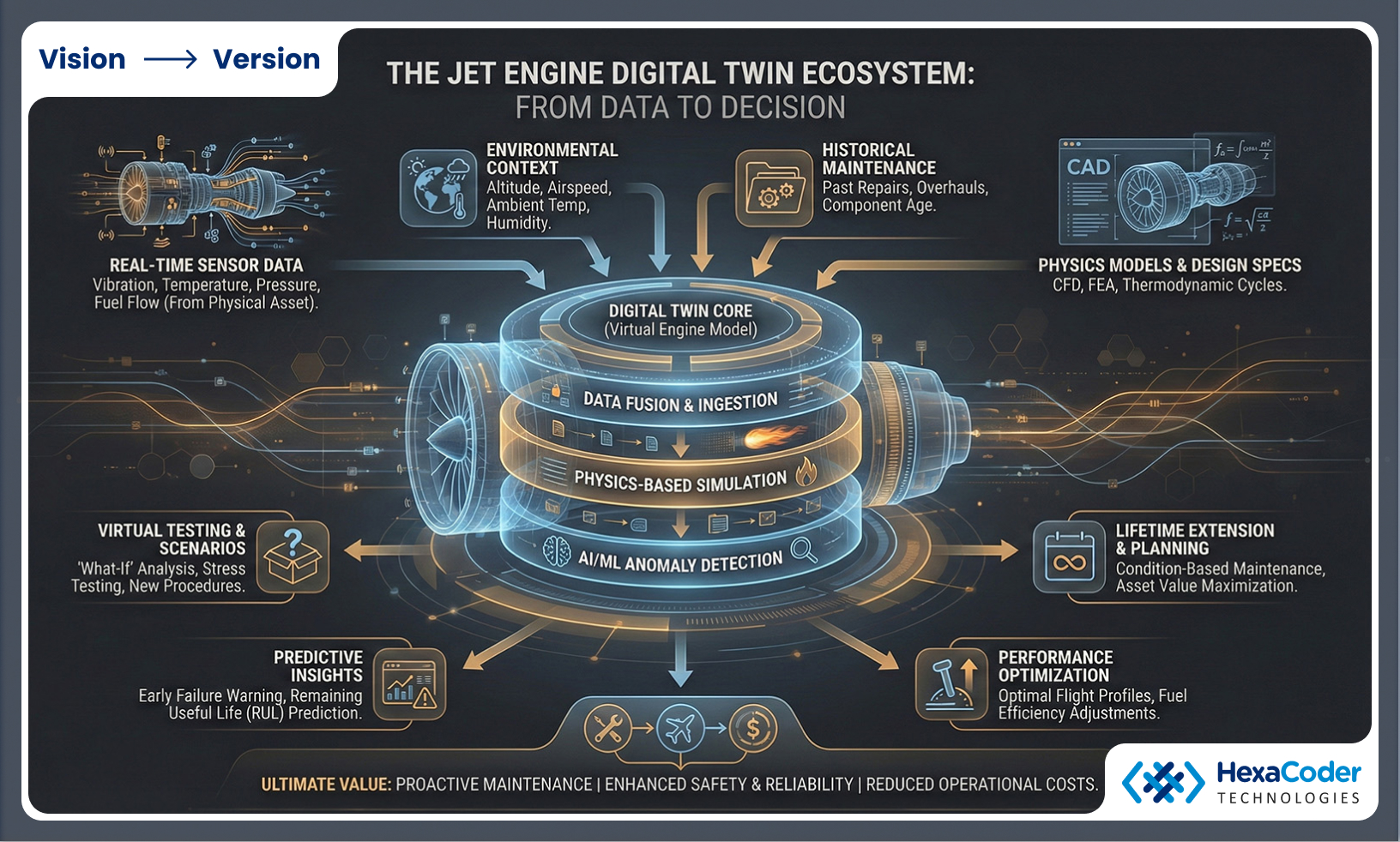

Supporting Lifecycle Management and Long-Term Asset Value

Jet engines represent the most intricate and costly assets in aviation which maintain their operational capacity for multiple decades. The operational and maintenance decisions made during maintenance and overhaul processes determine the system's reliability and total expense of ownership and asset value at termination. The existing method of managing complex systems through incomplete documentation and scheduled checks causes major limitations to efficient long-term system assessment.

Digital twins establish continuous engine lifecycle tracking through their ability to create a complete history record which documents each engine's operational lifespan. The system documents every operational hour together with maintenance activities and environmental exposure and performance modifications that occurred in the engine twin system. The system establishes an active asset history that develops together with engine changes instead of using fixed points which occur during inspection periods.

The complete lifecycle visibility system enhances decision-making capabilities throughout the entire aerospace industry. The system enables operators to schedule maintenance and overhaul procedures based on actual equipment condition assessment which results in better operational availability and reduced maintenance expenses. MRO providers gain enhanced understanding of failure modes and component degradation processes and maintenance effectiveness through their acquired knowledge. Manufacturers obtain digital twin data from multiple fleets to enhance their upcoming engine programs through enriched design capabilities and material evaluation and durability predictions.

Digital twins serve as vital components for asset valuation during both asset valuation processes and leasing decision-making activities. The asset transfer process requires accurate lifecycle records to enhance transparency during both asset transfers and lease returns and resale negotiations. The digital twin system achieves operational data linkage to engineering intent to establish design assumption feedback loops which connect design intention with actual performance results. The established connection between design intention and actual operational performance serves as a core method to enhance asset value while reducing lifecycle unpredictability and building trust between all parties involved.

Enhancing Safety and Regulatory Compliance

Safety and regulatory compliance remain essential requirements for aviation operations which face particular challenges in jet engine operations because their failure tolerance needs to remain extremely low. Engines must comply with strict certification standards which require continuous airworthiness monitoring and operational life reporting throughout their entire service period. Traditional compliance systems depend primarily on scheduled inspections which require manual documentation and after-the-fact analysis to assess risks, thus limiting their ability to detect early potential threats.

The digital twin solution enhances safety through its ability to provide real-time monitoring functionality which enables detection of abnormal system behavior early in the process. The digital twin system uses real-time sensor data together with physics-based and performance models to detect minor changes that might indicate potential faults and material fatigue and abnormal operational stress. The insights enable operators to take action before problems turn into safety incidents or flight interruptions or unplanned aircraft groundings.

Digital twins provide enhanced audit capabilities through their ability to improve traceability and readiness for audit processes. The twin system automatically records all maintenance activities together with performance data and system configuration changes and operational system failures through a structured time-stamped system. The system creates an authentic digital record which enables organizations to complete their regulatory obligations while conducting audits and validating compliance activities.

Aviation authorities are shifting towards data-based oversight and predictive safety management which makes digital twins essential for organizations to transition from active compliance to preventive assurance processes. Continuous system monitoring of safety leads to improved reliability and operational resiliency while creating stronger regulatory trust which drives operational continuity.

Integrating with Aerospace Digital Ecosystems

The true value of jet engine digital twins emerges when they are embedded within the broader aerospace digital ecosystem. The current aviation sector relies on its operational networks which encompass flight operations software and maintenance planning tools and ERP platforms and engineering databases and condition monitoring systems. An independent digital twin can only create limited effects because its complete potential becomes actual operational decision engine through system-wide integration. Jet engine digital twins acquire aircraft sensor data together with maintenance records and operational schedules and environmental data, which they use to provide insights back to the planning and execution systems.

The system creates workflows which operate in closed loops because predictions function as direct causes for operational activities. The automated system uses predicted component health decline to adjust maintenance schedules and start spare parts planning and make flight assignment decisions. Digital twins achieve their purpose by breaking down data silos which permit teams to obtain timely insights into their work. The entire team which includes engineers and maintenance planners and operations managers and leadership can access real-time engine behavior and risk data. Decision-making processes experience enhanced speed and uniformity through system intelligence which replaces traditional report-based decision systems.

The integration process becomes essential for organizations which need to oversee extensive vehicle fleets across numerous operational sites. The organization achieves enterprise-wide digital twin deployment through its management of both digital twin scalability and digital twin operational control and digital twin governance.

HexaCoders’ Approach to Jet Engine Digital Twins

HexaCoders designs jet engine digital twin solutions with a strong emphasis on real-world aerospace constraints, operational reliability, and measurable business outcomes. Safe operations depend on specific safety margin which HexaCoders protects through their use of dedicated digital twin engines rather than their adoption of universal digital twin platforms. The solution contains components which operate according to the complete engine design and sensor network and specific operational environment and performance goals of the engine operator.

Fidelity stands as the main principle which governs HexaCoders' digital approach. Digital twins are constructed using a combination of live sensor data, operational parameters, and engineering logic that reflects real engine physics and degradation behavior. The company directs its operations toward delivering valuable insights rather than developing visual displays. The engine-powered digital twin system develops through various engine enhancements which identify abnormal engine behavior patterns and generate predictive maintenance predictions and fuel efficiency and performance improvement possibilities.

The organization uses operational relevance as its major decision framework. Digital twins receive their data foundation through operators' existing flight operations data and their maintenance work and their condition monitoring work. The system enables quick value delivery because it creates minimal deployment disruptions. The twin uses generated insights to create decision support resources which include maintenance schedule adjustments and component replacement planning and operating procedure modifications for wear reduction.

The process of delivering major results depends on successful integration work. Digital twins developed by HexaCoders operate automatically with the current digital aerospace systems which include maintenance planning tools and ERP platforms and engineering databases and fleet management systems. The system enables closed-loop workflows which allow analytics results to directly move into execution as insights. The system uses predicted component degradation to create automated maintenance planning and spare parts provisioning and operational adjustment processes.

The organization gives equal attention to both scalability and usability. The digital twins of HexaCoders serve as actual operational tools which engineers and maintenance planners and reliability teams and decision-makers use throughout their daily work activities. The design of system interfaces and output formats follows standard workflows which permits employees from various departments to use the system. The organization improves engine reliability while reducing operational costs and enhancing safety through its deployment of digital twins in actual operational environments.

The organization sustains engine reliability improvements through digital twin deployment which provides measurable operational results. The system delivers enhanced monitoring capabilities which empower intelligent resilient systems to operate in complete management of jet engine fleets through all their operational stages.

Conclusion: From Monitoring to Intelligence

The process of engine monitoring and management in jet engines undergoes a fundamental transformation through the implementation of digital twin technology. The traditional system uses scheduled inspections and threshold alerts together with retrospective analysis to provide limited risk detection, which results in delayed emergency responses. Digital twins provide organizations with ongoing predictive analysis through which they can assess engine conditions and operational risks.

Digital twins convert sensor data into operational insights through their combination of real-time data and engineering and physics-based models. Operators acquire the capability to identify developing problems before they become serious faults while they simultaneously optimize performance and determine maintenance requirements through actual engine conditions. The new approach enhances system reliability and decreases both unplanned equipment failures and maintenance activities that are not required.

Digital twins enhance safety assurance through their main functionality. The system uses continuous monitoring to identify problems early because it delivers constant surveillance of operations. Digital records provide complete documentation which enables the industry to meet regulatory requirements while maintaining traceability and audit readiness to verify documentation and accountability requirements.

Existing monitoring methods cannot keep up with the increasing technological challenges and rising operational demands of modern jet engines. Modern fleet management needs tools that can handle complex situations and unpredictable outcomes while maintaining operational safety and efficiency. Digital twins deliver the required intelligence layer which helps organizations achieve their objectives with exactness and certainty.

The aerospace manufacturing industry and MRO service providers and operators now consider digital twins to be essential technologies instead of experimental options. The organization provides a vital ability which enables safe operations and reliable performance and competitive advantage for the long term. Digital twins create a new engine management method because they help organizations track engine performance, safety, and operational trustworthiness in the aerospace sector which links those three elements together.