How Digital Twins Optimize Production Line Performance

Digital twins constitute a fascinating technology that is reshaping how production lines optimize their performance. In view of increased product realization and complexity, the modern production lines are under constant pressure to deliver higher throughput and consistent quality at lower costs. Basing their conclusions on historical data, audit observation, and post-mortem analysis, the traditional methods of manufacturing optimization offer only fleeting insights, and these inadequately describe the prevailing dynamic interconnection of modern production environments. Digital twins essentially close this gap by serving as a living, continuously updated virtual representation of the production line that is contemporaneous to real-world behavior tracking in real time.

Digital twin technology becomes a principal opportunity for operationally minded manufacturers to optimize performance, decrease downtime, and integrate data-driven decisions throughout the lifecycle of production.

Understanding Digital Twins in Production Line Environments

A digital twin of a production line is far more than a 3D view of machines and conveyors. The digital twin is a living system fed with real-time data from equipment, sensors, control systems, quality stations, and enterprise platforms that together are used to mirror real operating conditions. The digital twin evolves continuously as the production proceeds, reflecting all changes in machine states, material flow, cycle times, and process parameters.

Perhaps the most interesting aspect of how digital twins can help production environments is their ability to maintain relationships. Production lines are tightly coupled systems: a bottleneck, failure, or inefficiency at one station has effects both downstream and upstream. Digital twins are able to capture these relationships holistically, enabling manufacturers to understand how local issues propagate across the line.

With the system view provided by such twins, teams are enabled to go beyond isolated performance metrics and begin optimizing the entire flow of production.

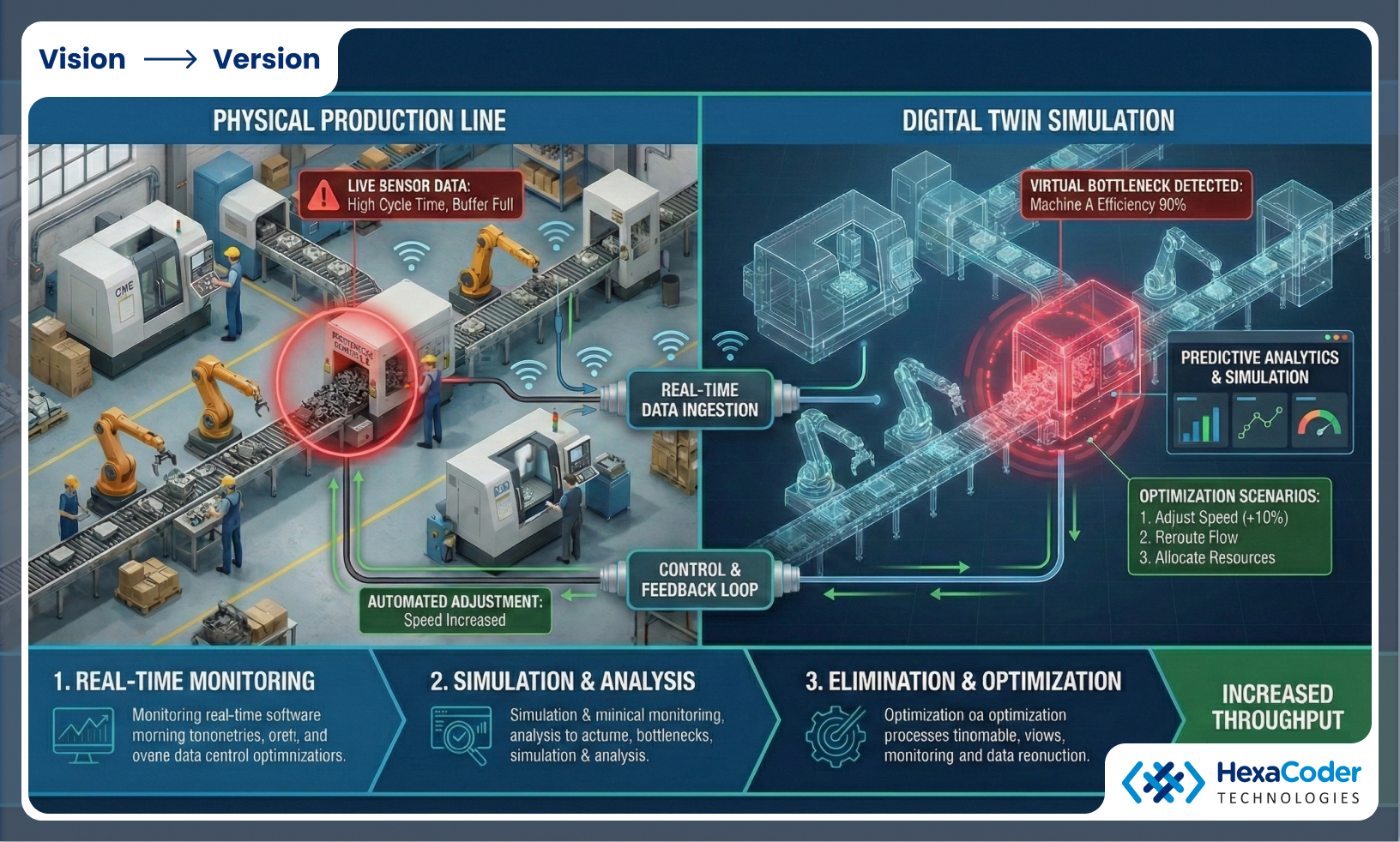

Identifying and Eliminating Bottlenecks in Real Time

Bottlenecks remain one of the most prevalent challenges on the production line. Traditionally, they have been identified by observing diminishing throughput since the onset of backlogs. By the time a corrective action is taken, production has borne losses.

Digital twins change this narrative by monitoring cycle times, queue lengths, machine utilization, and material flow rate across the entire line. Any time performance at a station starts diverging from expected, the digital twin immediately highlights this emerging constraint.

More importantly, the digital twins then provide context as to why that bottleneck is forming. The root cause may be an effect of equipment wear, operator variability, material shortages, or disruption upstream; the digital twin provides context to intervene instead of sending isolated alerts.

Insights gained from the digital twin may facilitate supervisors' decision-making to rebalance workloads, slow down or speed up the line, or redirect production altogether to avoid hitting throughput. With time, this application of bottleneck management would result in a smoother flow, better line utilizations, and more predictable output.

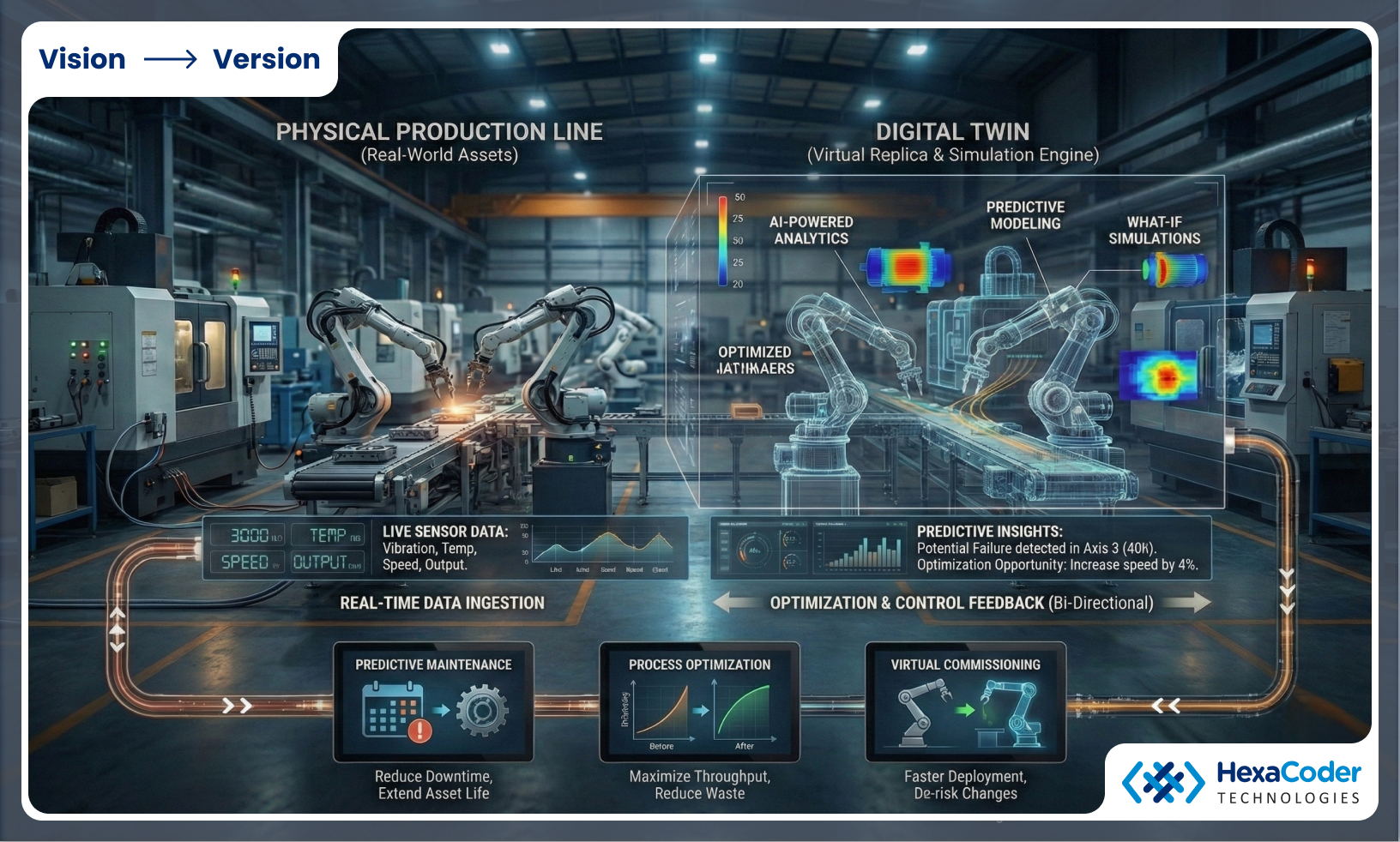

Optimizing Equipment Utilization and Reducing Downtime

Unplanned downtimes truly create the most significant portion of production loss. While most manufacturers do collect data for their equipment, such data often fail finding a way to be translated into applicable knowledge. Digital twins serve to provide such a context for machine data to operate within a broader context of production.

By integrating vibration, temperature, power consumption, and cycle count information, the digital twin builds a behavioral model of each asset. Deviations from normal operating patterns are detected early, often before a failure occurs.

Unlike predictive maintenance tools, which might work in isolation, digital twins assess the operational impact of a potential failure. Manufacturers can simulate what happens if a machine is taken offline, delayed, or repaired at different times. This makes it possible to schedule maintenance in ways that minimize disruption to production.

In this case, downtime can be planned and not necessarily reactive. Equipment availability is enhanced by this and maintenance resource utilization is optimized, leading to increased OEE across the production line.

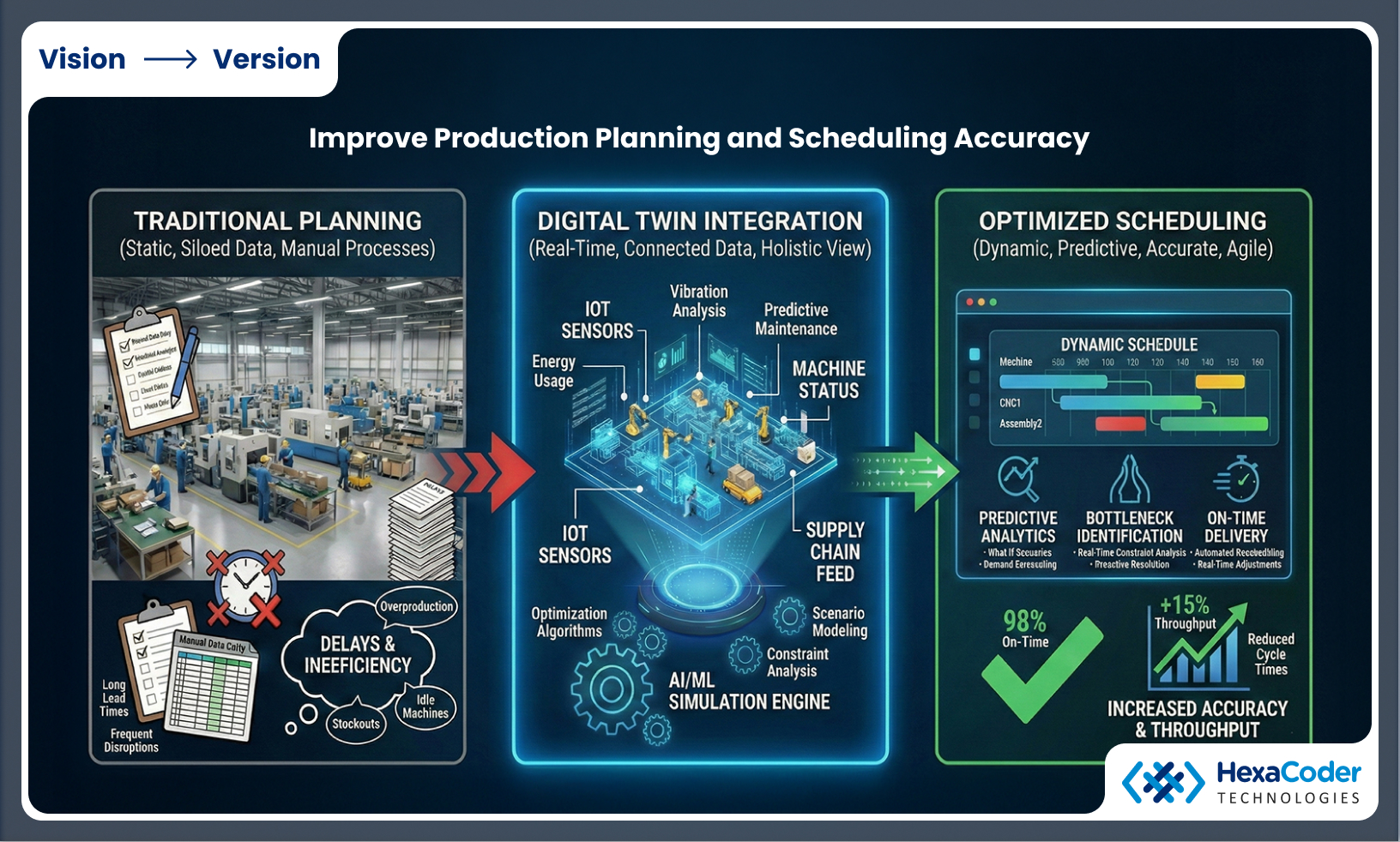

Improve Production Planning and Scheduling Accuracy

Production planning often assumes capacities, lead times, or resource availability. In production environments, these assumptions often turn out to be dynamic in nature with constant demand variation, machine performance, and material supply variation.

Digital twins allow for dynamically updated production planning by continuously updating capacity modeling against real-time conditions. The planners can simulate various schedules, batch sizes, or sequencing strategies and assess the impact on throughput, lead time, and resource utilization before making any changes to the shop floor.

This becomes very useful in high-mix or customized environments where variability is a fact of life. The planners have decided to rely on a digital twin, balancing conservative buffers or perceived manual adjustments, and this option, of course, minimizes risk.

Over a prolonged time, this improves schedule adherence, lowers work-in-progress inventory, and increases responsiveness to fluctuations in customer demand.

Improving Quality Control and Process Stabilization

Quality problems arise from fine deviations in the process that are very difficult to recognize with traditional inspection methods. By the time an entity is recognized as a defect, considerable value would have been lost.

Digital twins provide added capabilities for quality control by relating the process parameters with quality results through the production line. Parameters including temperature, pressure, speed, alignment, and material characteristics are continuously monitored and analyzed in context.

When the digital twin detects conditions that historically correlate with quality defects, it can alert operators or automatically adjust process parameters to maintain stability. This shift from reactive inspection to proactive quality control reduces scrap, rework, and warranty costs.

For manufacturers that are bound by regulatory or customer quality standards, digital twins create full traceability and transparency of the entire production activity. The operating condition of every unit produced can be traced back to its exact operating conditions, thereby facilitating the audit and continuously improving schemes.

Supporting Continuous Improvement and Lean Manufacturing

Continuous improvement programs revolve around accurate measurement and repeatable experimentation. However, testing changes directly on live production lines is risky, time-consuming, and disruptive.

Digital twins provide a safe environment for experimentation. Manufacturers can simulate process improvements, layout changes, staffing adjustments, or equipment upgrades without interrupting production. The impact of each change can be evaluated quantitatively before implementation.

This capability accelerates improvement cycles and reduces resistance to change. Teams gain confidence because decisions are supported by evidence rather than assumptions.

Over time, digital twins become a core enabler of lean manufacturing practices. Waste is identified systematically, variability is reduced, and processes are continuously refined based on real operational data.

Improving Energy Efficiency and Sustainability Performance

For manufacturers, especially the energy-intensive ones, energy efficiency has turned into a key operational and strategic priority as it addresses margins and issues of regulatory compliance. Traditional energy monitoring approaches pay attention mainly to aggregated facility-level metrics offering limited insight into where inefficiencies actually originate. It is rare that such data indicate exactly which processes, machines, or operating conditions are to blame for rising energy costs.

Digital twins address this limitation by linking energy consumption directly to production activities at a granular level. By integrating data from machines, sensors, and control systems, a digital twin creates a real-time model of how energy is consumed across each stage of the production line. Manufacturers can clearly see how individual machines, shifts, product variants, and operating parameters influence energy usage. This level of transparency makes inefficiencies visible and actionable rather than hidden within averages.

Beyond monitoring, digital twins enable manufacturers to simulate alternative operating strategies before implementing them physically. Scenarios such as load balancing across equipment, adjusting line speeds, sequencing high-energy processes differently, or optimizing start-up and shutdown cycles can be tested virtually. These simulations allow manufacturers to reduce energy consumption without compromising throughput, quality, or delivery commitments.

In instances where sustainability targets and emissions regulations are defined with increasing stringency, digital twins afford the analytical foundation that is leveraged to support compliance and reporting. Emissions, energy intensity, and resource usage can all be tracked relative to actual production output, allowing for credible sustainability metrics. Instead of treating sustainability as a separate initiative, digital twins embed energy optimization directly into daily operational decision-making, aligning environmental responsibility with manufacturing performance.

Improving the Cross-Functional Decision Making

Now production line performance is the product of decisions made across several different functions: engineering, maintenance, quality, supply chain, and, at the end of it all, executive leadership. In many organizations, most of these teams operate with different systems, data sources, and performance metrics, leading to misaligned priorities, delays in decision-making, and localized optimizations that could hinder the overall performance.

Digital twins create a unified operational model that these voices share. All stakeholders retrieve the same data and look at the same system behavior; engineers see how design or process changes affect throughput; maintenance teams know how asset availability decisions impact production; and quality teams can link defects to real operating conditions rather than isolated incidents.

This shared context greatly improves quality and speed of decisions. Instead of squabbling over who is right on data issues or the impact of decisions on departments, teams can argue solutions within the same digital environment. Decisions become clearer instead and are made with a system-wide perspective rather than a departmental optimization ones.

For organizations with multiple production lines or sites, digital twins become the networking basis for all performance management while still allowing local flexibility. A best practice that has been found in one facility can be tried out and adapted digitally before rollout elsewhere. Leadership now also gets visibility across operations with regard to much more informed strategic decisions than through delayed and inconsistent reports. This results in stronger alignment, faster execution, and much more resilient manufacturing operations.

Fusing with Existing Manufacturing Systems

The best value from the digital twin comes from its close coupling with the existing manufacturing technology stack. Stand-alone models or visualization tools might give some insights, but as they do not translate into operational action most of the time, such insights finally become meaningless. Only then do digital twins become transforming agents when they act within a connected ecosystem.

Production orders, availability of material, states of machines, schedules for maintenance, and metrics of quality flow into digital twins automatically, enabling continuous ingestion of real operational data through the integration with MES and so on and also ERP types, SCADA, PLM, or quality management platforms. Thus, virtually, anything reflects up-to-date reality rather than some constant assumption.

Important is closing the loop as well with feedback. Operational systems could be fed with insights those gain from a digital twin, for example, optimized schedules, maintenance recommendations, or process changes, for execution. This would minimize human interventions, errors of interpretation, and speed up response time.

Digital twins are connective intelligence layers that otherwise separate systems and integrate them into one. It reduces the silos found in organizations to favorable conditions for decision-making in planning, execution, and optimization. Instead of making a new tool for an already complicated IT landscape, what it will bring about is a coherent operational model that links data to logic. Thus, optimization will be a part of the daily workflow, not treated as an exercise separately but embedded in existing systems.

How HexaCoders build a digital twin for production lines?

HexaCoders views digital twin implementation with a transparent reality check for manufacturing results. HexaCoders does not take the typical generic platform, but rather, develops production line digital twins for each manufacturer with respect to the specific processes, constraints, and operational objectives in question. This guarantees relevance, usability, and measurable impact from day one.

Machine-level data, process logic, and enterprise systems make up the digital twins of HexaCoders. The replicas of the production environment are accurate and action-oriented replicas, but the focus is not on visualization. This is designed with decision support. Insight into the greatest performance-limiting issues such as downtime, inefficiencies, quality variation, and bottlenecks will be made available to manufacturers.

The real differentiator is in the pragmatic rolling out of the application. In addition, HexaCoders partners with manufacturing teams to realize digital twins that are complementary to existing workflows, skill levels, and system landscapes. Implementation is intended to be gradual and scalable, as opposed to requiring a disruptive transformation that will support ongoing improvements.

By hence anchoring its digital twin design to the realities of manufacturing, its long-term adoption and value creation are consequently assured. Daily operational tools for engineers, supervisors, and planners, digital twins become not separate analytics projects run by experts. Such an execution-first strategy will see manufacturers take strides of improvement in throughput, efficiency, and resilience.

Conclusion: The Transition from Monitoring to Optimization

Transforming production line performance management, digital twins radically redefine it. Traditional manufacturing systems are only fixed at monitoring and reporting on performance, often placing reactive measures on performance after the situation faces some degradation. Digital twins move from this direct shift to continuous optimization - a combination of real-time visibility, predictive insight, and scenario simulation under the same roof.

Besides simulating actual operating conditions and behavior of the systems, digital twins will help a manufacturer foresee many issues, revisit and refresh decisions prior to execution, and potentially optimize performance proactively. Bottlenecks are mitigated early on, downtime planned rather than reactive, and improvements validated digitally prior to rollout.

As production environments become more complicated and profit margins more constricted, such capability is now mandatory. This gives the groundwork for intelligent, adaptive manufacturing systems that can respond to the flows without sacrificing efficiency or quality.

Digital twins are to manufacturers aiming at operational excellence and future readiness beyond a technological upgrade; they are actually a strategic capability for transforming production lines from mere monitored systems to optimized, resilient, and ever-improving operations, speeded up to real-time decision making.