The construction and infrastructure industry is undergoing a fundamental transformation. The existing approaches for planning and executing and managing assets must be replaced because projects now require greater size and complexity and enhanced interconnectivity. Developers and contractors and asset owners worldwide face ongoing difficulties from delays and cost overruns and safety risks and sustainability requirements.

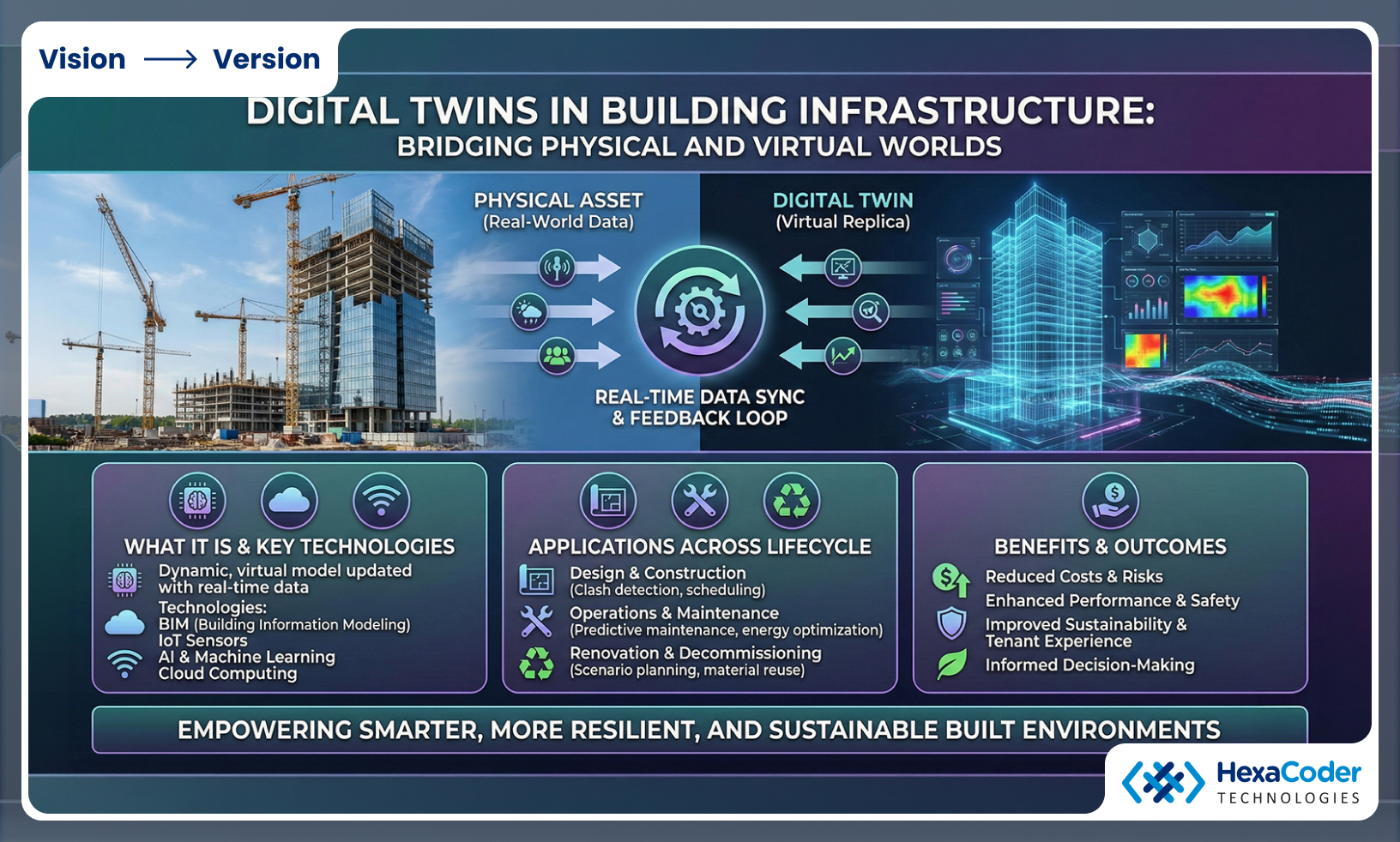

Digital twin technology has emerged as a powerful solution to these challenges. Digital twins create a dynamic virtual model which uses data to provide stakeholders with the tools to accurately design and build and operate and maintain infrastructure.

Digital twins have developed into essential tools which organizations use throughout the complete asset management process for their infrastructure projects which include commercial buildings, industrial plants and airports and hospitals and smart cities. They serve as a strategic resource which enables organizations to make superior decisions on their asset management throughout all asset management stages.

The most critical digital twin operational components for building infrastructure projects. A digital twin functions as an active digital representation of a physical object which receives continuous updates from actual world information. The building infrastructure system uses this data to create architectural models and structural systems and mechanical and electrical networks and occupancy data and environmental conditions and energy usage and operational performance data.

Understanding Digital Twins in Building Infrastructure

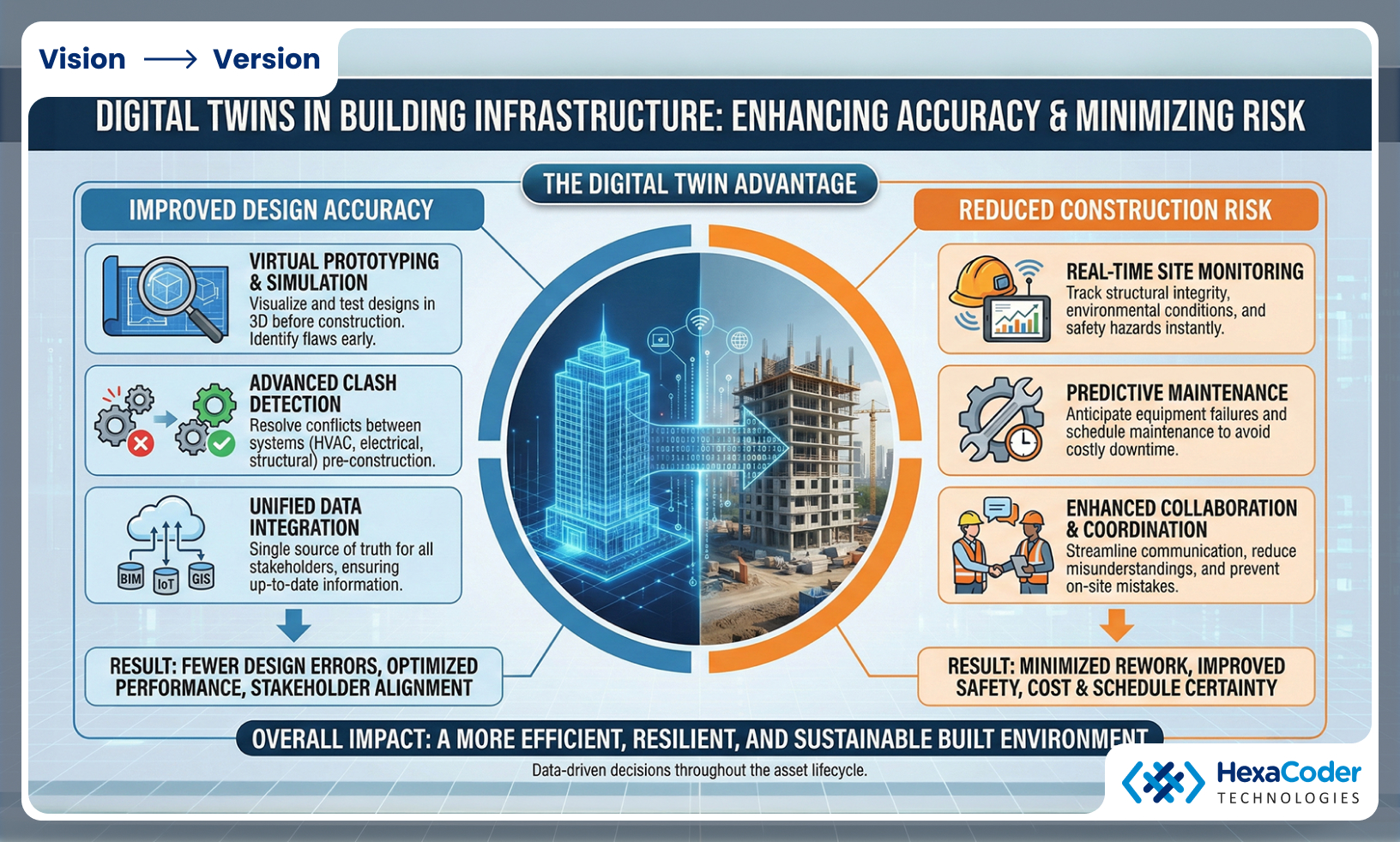

Digital twins enable complete building verification which architects and engineers can use before starting construction work. The project team uses digital twin technology to create simulations of how all different system components will function together under various conditions. The team can conduct comprehensive analysis of load behavior and airflow and thermal performance and spatial conflicts.

Digital twins help reduce construction uncertainty by identifying design issues at an early stage which prevents errors from carrying over to the construction process. The process leads to a decrease in change orders while enhancing design discipline coordination and streamlining the shift from design work to construction work.

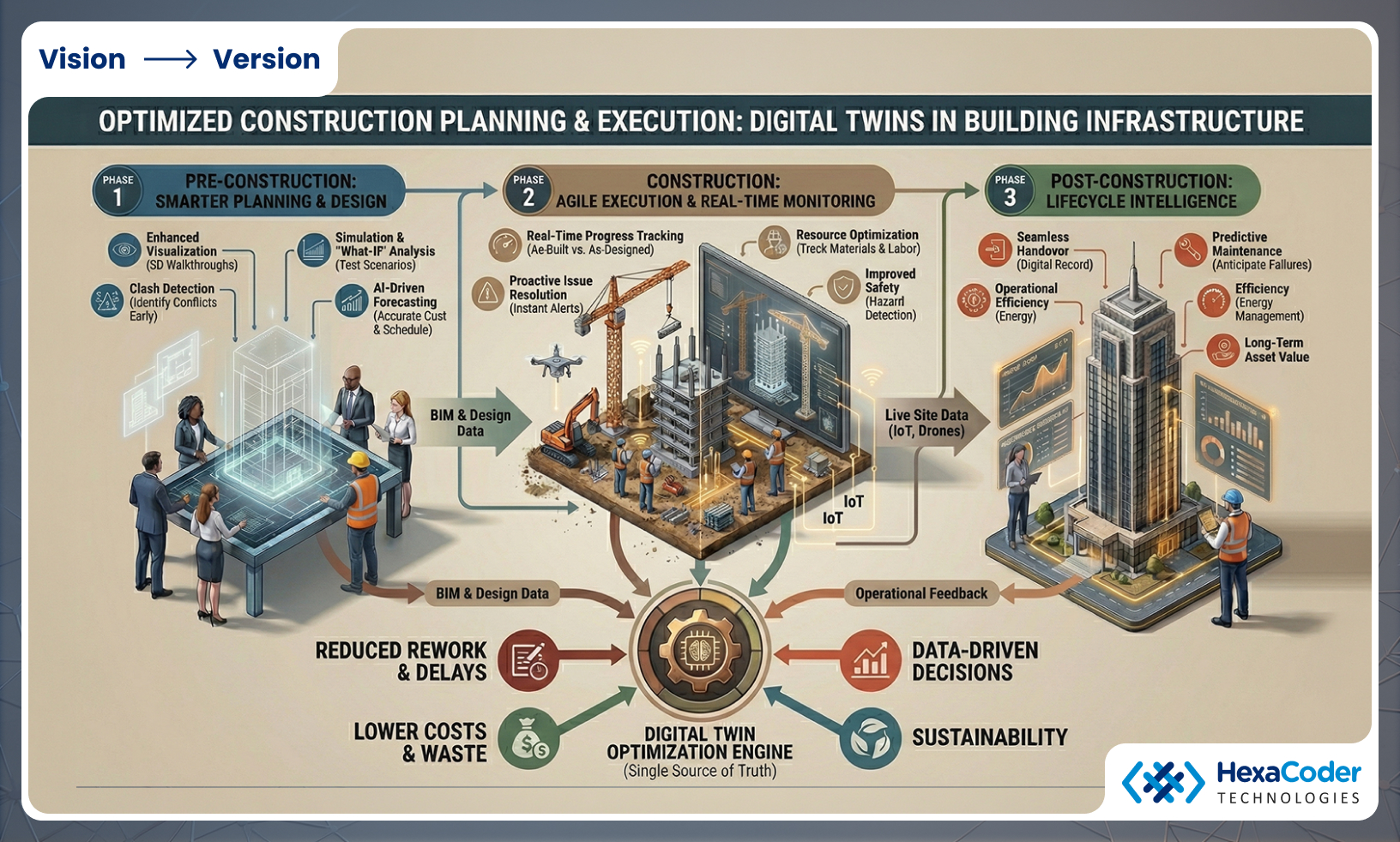

The construction project requires effective planning and execution for its successful completion. The construction site functions as an active zone where any delay in one task causes delays throughout the entire project. The available project planning tools do not function according to current project status which creates challenges for effective disruption management.

Improved Design Accuracy and Reduced Construction Risk

Digital twins establish a connection between building time schedules and actual site operations. The digital twin framework shows project teams all elements which include tracking progress and handling material shipments and managing equipment usage and defining workforce distribution. The project teams obtain instant access to unplanned events which enables them to run simulations for all necessary corrective actions before executing them at the project site.

The system enables organizations to identify upcoming obstacles which leads to improved timetable accuracy and efficient resource allocation. Construction managers on the project handle their problem-solving tasks by establishing work connections between different teams which helps them minimize operational delays while achieving higher productivity levels throughout the entire project duration.

Optimized Construction Planning and Execution

Construction sites operate as unpredictable places because delays in any work task will create delays for the entire construction project. The existing project planning tools fail to capture actual site conditions which makes it impossible to handle disruptions through preventive measures. Digital twins connect construction schedules with real-time data from construction sites. The digital twin displays progress tracking together with material deliveries and equipment usage and workforce allocation. Project teams can instantly see when their work strays from the established schedule through their ability to test various solutions prior to actual field work execution. The capacity to identify potential bottlenecks results in better schedule accuracy together with improved resource utilization. Construction managers shift from fixing problems after they happen to organizing work in advance which leads to less downtime and higher efficiency throughout the entire project duration.

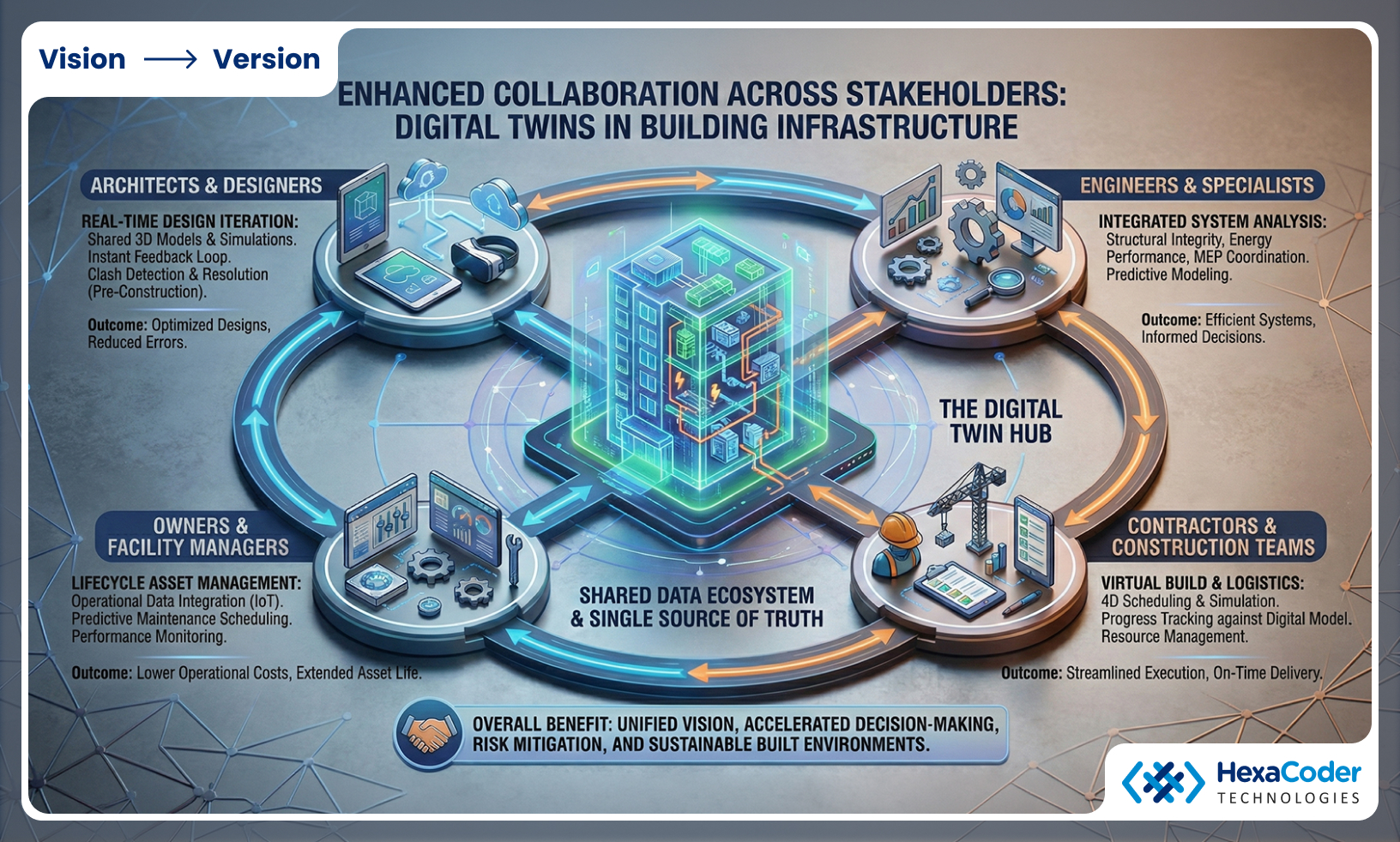

Enhanced Collaboration Across Stakeholders

Infrastructure projects need architects and engineers and contractors and owners and facility managers and regulators to collaborate their efforts. The groups involved in the project work together but their different interests create both inefficiencies and conflicts between them. Digital twins establish a shared digital environment which enables all stakeholders to access the same source of truth. The unified model displays design intent and construction progress and operational data together. The transparent system improves communication between parties which leads to fewer misunderstandings while enabling quicker decision-making processes. The digital twin allows stakeholders to work together on issue resolution while they test different solutions to determine system-wide impacts. The shared context improves coordination between teams while decreasing expensive delays that occur when information gets scattered across multiple locations.

Real-Time Monitoring and Performance Visibility

Building operators face difficulties because they need to monitor building performance yet need to keep building systems running normally. Facility management systems from the past create data silos which deliver isolated information without offering contextual details or predictive capabilities. Digital twins operate by combining operational data from all building systems which include HVAC systems and lighting systems and energy systems and water systems and elevator systems and security systems. Facility managers can observe performance in real time while they gain complete understanding of current events and their underlying causes. The system-level visibility enables rapid issue resolution because it helps teams handle equipment faults and comfort complaints and energy spikes. Teams who receive alarms can stop reacting to each alert which interrupts their workflow. The team uses this method to investigate the problem from all sides which enables them to detect the main cause of the issue and take specific measures to fix it.

Predictive Maintenance and Reduced Downtime

Unplanned equipment failures in building infrastructure create disruptions to operations which lead to safety hazards while increasing maintenance costs. Traditional maintenance strategies work based on two methods because they either use time-based maintenance schedules or wait until machinery breaks down to conduct repairs. Digital twins enable predictive maintenance through their capability to detect early signs of equipment degradation. Digital twins use real-time sensor data to create failure prediction models which compare current data to engineering models and historical data patterns. Maintenance schedules can be created ahead of time which helps to reduce operational downtime while increasing the lifespan of equipment. The approach provides hospitals and airports and industrial plants with improved reliability while delivering cost savings on their future operational expenses.

Energy Efficiency and Sustainability Optimization

Building infrastructure requires energy-efficient solutions which now serve as strategic sustainability initiatives that help organizations meet their sustainability targets and regulatory requirements while increasing their asset worth. Energy management systems from the past depend on organizations to monitor their energy use through historical records combined with scheduled energy assessments and they must wait until problems appear before making necessary changes. The existing methods which humans use presently to create modern building systems show their deficiency to handle ongoing changes which take place in building occupancy and weather patterns together with system interconnections.

Digital twins operate as a basic energy management tool because they build a continuous operational model of building which draws from real-time building performance data. Digital twins enable complete energy distribution analysis through their ability to integrate real-time data from HVAC systems and lighting systems and power distribution systems and sensors and smart meter systems. Facility managers investigate all operational areas to find inefficiencies which include equipment performance problems and excessive energy consumption during low occupancy times and incorrect control methods.

Improved Safety and Risk Management

Safety in building infrastructure extends across multiple areas which include construction activities, equipment operations, occupant movement, and emergency preparedness. Safety management systems used to operate through the use of fixed safety documentation which required staff to conduct physical inspections and safety inspections conducted at specific times throughout the year. The protective measures which these methods provide show their capability to establish baseline defenses while they struggle to manage spontaneous dangers which develop during developing situations.

Digital twins create a safer environment through their ability to deliver constant situational awareness throughout all areas of a building. Digital twins provide users with a real-time situation analysis which shows all building dangers through their system which integrates structural sensor data with environmental monitoring data and surveillance feed data and IoT device data. The system includes equipment stress detection and temperature detection and air quality detection and overcrowding detection which enables early action before problems lead to major incidents.

Digital twins offer two main functions which include monitoring operations and performing complicated risk simulations. Virtual testing allows users to assess emergency situations which involve fires and power outages and system failures and evacuation protocols. Facility managers use these simulations to see the way building spaces work as dangerous spaces while they develop methods to handle events which happen during different building areas. Emergency planning processes allow upgrades which will not risk staff and occupant safety through their use of actual dangerous areas.

Lifecycle Asset Management and Long-Term Value

Buildings function as long-term financial assets which experience gradual changes in their operational quality and energy efficiency and their ability to adapt to new circumstances throughout their entire lifespan. The results of design and construction decisions will determine three main aspects which include operational expenses and maintenance needs and future adaptability of the project. Traditional asset management systems experience difficulties because they lack complete data and essential documents and their asset performance information remains hidden from view.

Digital twins offer a solution to these problems by establishing a permanent digital record which tracks building operations from its beginning to its end. The digital twin records every operational modification together with every maintenance task and every performance indicator which results from building activities between design and construction through to daily operations and building renovations. The centralized intelligence system removes information silos which prevents data access from different teams and vendors and technology transitions.

Facility managers use digital twins because these systems enable them to schedule maintenance work through predictive methods instead of waiting for equipment problems to occur. The system detects equipment failures through analysis of equipment performance and behavior trends. Maintenance activities should happen according to the actual condition of assets instead of following predetermined schedule times which results in less downtime and longer asset service life.

Digital twins enable organizations to make long-term maintenance decisions about their systems through their upgrade analysis and system expansion evaluation process. Building owners can evaluate how proposed modifications will affect building performance and operational expenses and environmental impact before they invest in construction work. This approach minimizes risk while providing assurance that investments will support the organization's strategic objectives.

Digital twins boost building asset value by maintaining operational flexibility together with operational efficiency and operational durability of buildings. Digital twin systems allow organizations to detect and manage upcoming changes which include new technology developments and regulatory requirements and emerging usage patterns.

Data-Driven Decision-Making Across Portfolios

The task of managing extensive infrastructure portfolios which include multiple buildings presents substantial operational difficulties. Performance data from various assets exists in different formats which have various levels of accuracy and accessibility. The team uses incomplete information together with high-level assumptions to make decisions.

Digital twins use a standardized data-driven framework to enable building portfolio management at large-scale operational facilities. The digital twin of each building keeps track of all performance information which includes operational data and past performance records. The process enables organizations to assess asset performance against each other while detecting performance trends which would have remained undiscovered.

Supporting Smart Buildings and Future Technologies

Modern buildings through their use of IoT devices and automation systems and AI-driven controls and occupant-facing technologies have become structured as complex systems which operate as interconnected networks. The true value of these innovations emerges from their ability to create data outputs which require advanced processing methods and contextual knowledge for proper implementation. Digital twins function as the primary control system which connects all smart building technologies into a unified central system. The system provides an integrated view of all components which allows users to analyze data from multiple sources through a single unified system. The building systems function through their combined operation which receives control signals from the digital twin system. Digital twins enable organizations to expand their operations through their capability to adapt to emerging technologies. Existing twin systems can receive AI-driven optimization methods together with advanced analytics and automation features which will operate without any interruption to current workflows.

HexaCoders' Approach to Building Infrastructure Digital Twins

HexaCoders creates digital twin solutions which base their design on actual building functions and outcomes of business operations. HexaCoders develops digital twin systems which match the specific needs of each infrastructure project instead of using standard digital twin platforms. HexaCoders combines design data with sensor inputs and building management systems together with enterprise platforms to develop intelligence which helps asset management throughout its entire lifecycle. The platform delivers three core benefits which include improved usability and scalability together with measurable results that reduce downtime while improving efficiency and safety and better lifecycle management. The digital twin system used by HexaCoders provides long-term value through operational deployment because it functions as a real-world operational system.

Conclusion: Digital Twins as a Strategic Infrastructure Capability

The introduction of digital twins has transformed building infrastructure development because it now defines the entire process from design to construction and operation. Intelligent systems which use predictive algorithms transform organizations from their traditional delay-based operational management approach. Digital twins deliver value through their capabilities which improve design accuracy and construction efficiency and operational performance and environmental sustainability and safety maintenance throughout the entire infrastructure lifecycle. Digital twins have transformed into essential tools which building owners and developers and operators require to meet their increasing operational needs. Strategic capability provides infrastructure systems which establish operational resilience and energy efficiency and future readiness. Digital twins represent essential technology investment which organizations must make to achieve their goal of maintaining top operational performance in building infrastructure. Smart built environments require digital twins as primary technology which supports sustainable development.