Best Blazer 3D Configurator Tools for Tailored Clothing

Digital transformation affects all areas of the apparel industry including tailored clothing. Consumers today expect not just quality but a personalized experience that allows them to create clothing that reflects their style, fit, and comfort. The unique characteristics of blazers make it difficult to design their tailored clothing. The final appearance and comfort of the product depend on various factors which include lapel style, sleeve length, fabric choice, lining, stitching, and button placement. Traditionally, these decisions required in-person fittings and consultations with tailors.

E-commerce growth and shifting consumer patterns force brands to determine how they can deliver online personalization that matches the boutique shopping experience. The 3D blazer configurator tools enable customers to create and view their custom jackets through live visualization. Advanced digital configurators allow shoppers to see realistic fabric textures, colors, and garment drapes on a virtual model, bridging the gap between online exploration and offline precision tailoring.

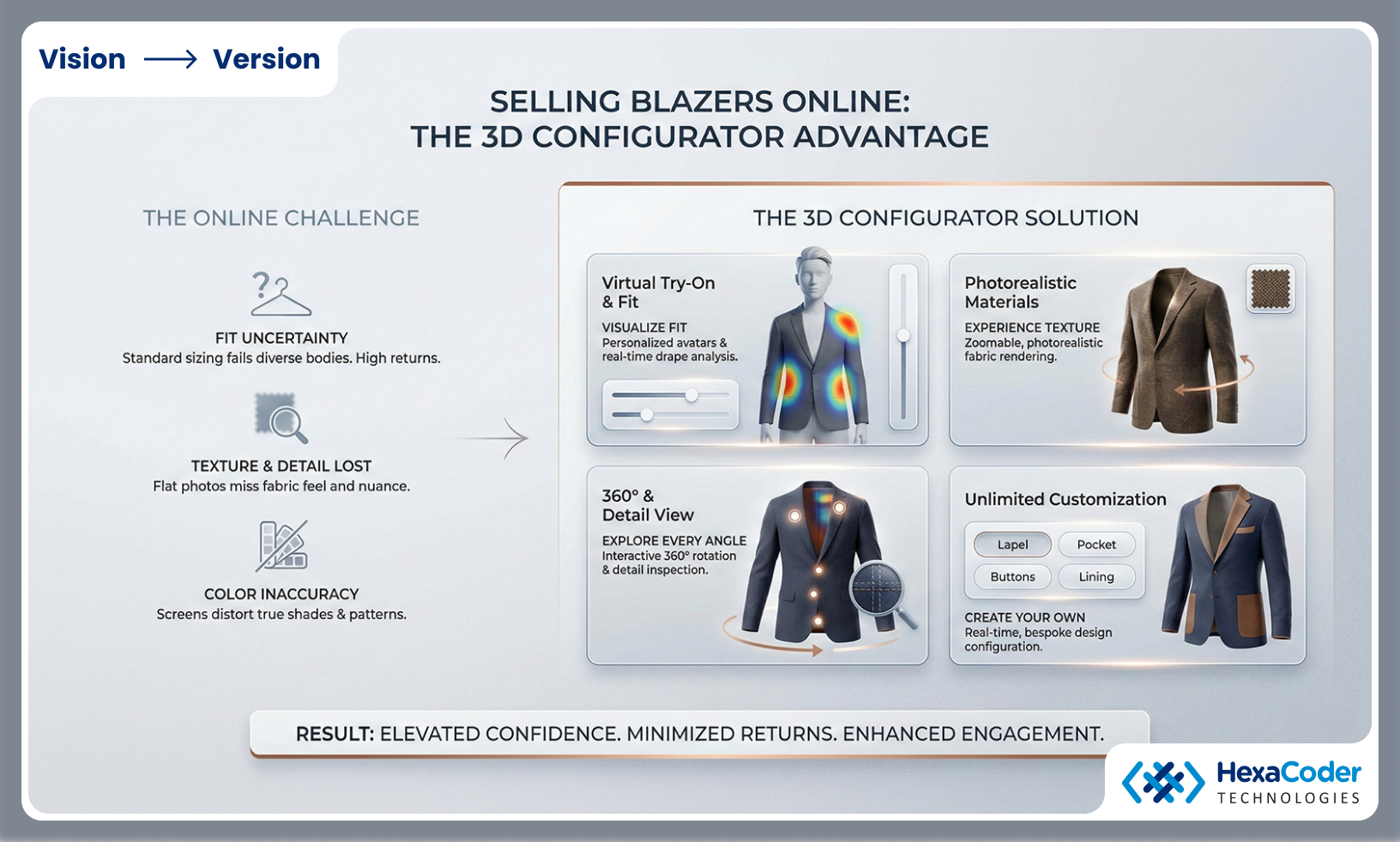

Why Blazers Are Complex Products to Sell Online

Blazers are inherently complex because they are not just fashion items; they are structured garments. The tailoring process needs exact measurements for all parts of blazers which include shoulders, chest, waist, and sleeves. The garment design will suffer from even the slightest measurement errors because they will cause problems that affect both the design and usability of the product. The customization process of blazers includes choosing from various options which contain lining styles, button designs, stitch patterns, and pocket locations.

The online sales process of blazers presents brands with major obstacles which they must overcome. Customers need to see how the jacket fits their body type and how the fabric looks in actual conditions before they will purchase. The details about texture and sheen and drape remain hidden even when high-quality images or videos are present. Customers who hesitate about making decisions will either leave shopping carts empty or delay their purchases or return items after buying. The revenue losses and customer dissatisfaction which premium tailoring brands experience result from their existing operational gaps.

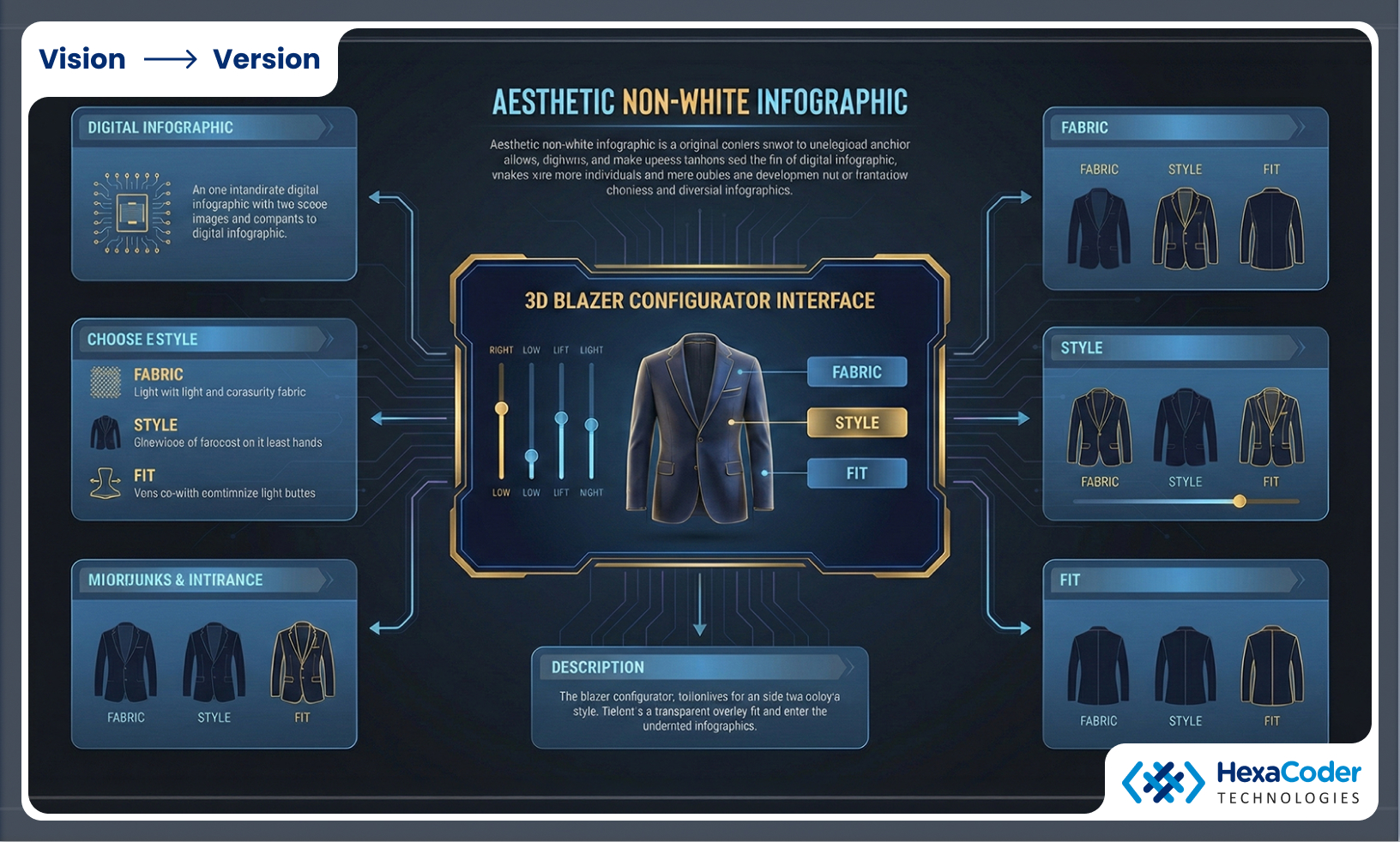

The Role of 3D Configurators in Tailored Clothing

The online shopping process uses 3D configurators to give customers the power to design their blazers through virtual design. Shoppers use a digital interface to view the garment in real time instead of viewing it through traditional photos or static models. The designers can choose their own fabrics and modify body dimensions while selecting lapel styles and trying different button and lining combinations.

The configurator ensures that every option displayed is feasible and manufactur-able. The configuration process requires advanced systems to follow the established tailoring standards together with the specific production limits. The customer has the option to design their own product but the end result will be a blazer that meets all necessary quality requirements while remaining production-ready. The experience creates confidence, reduces uncertainty, and gives brands a new way to engage digitally-savvy consumers who prioritize personalization and instant feedback.

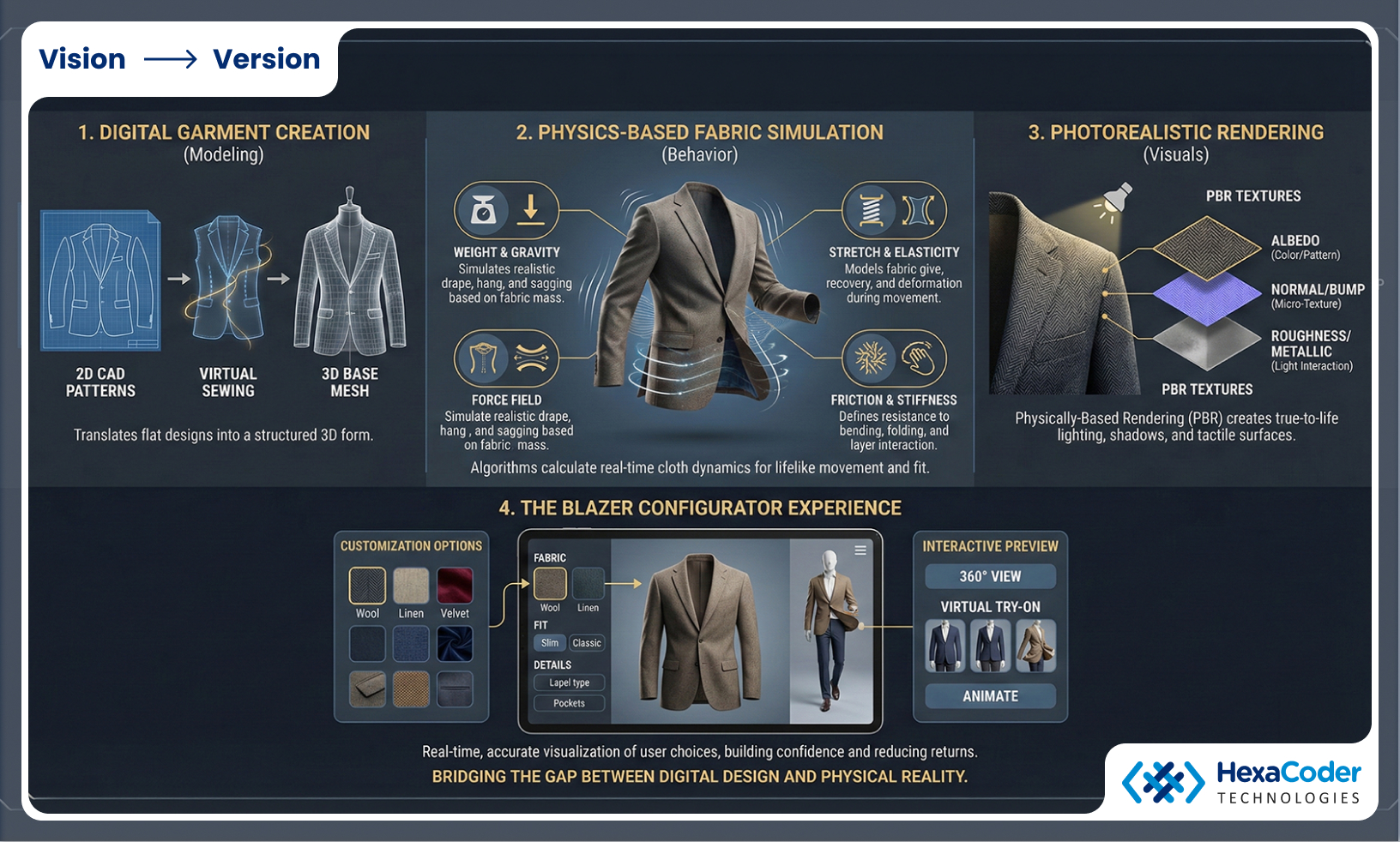

Realistic 3D Garment Modeling and Fabric Behavior

The blazer configurator achieves its purpose by providing a shopping experience which customers can trust through its realistic virtual representation. Customers want to understand not just how a blazer looks, but how it behaves when worn. The way fabrics drape and fold and react to different conditions changes according to their weight and weave and cut specifications. Wool material hangs heavier than linen and shows different structural properties while cotton fabric shows increased tendency to develop creases. Online shoppers need to see these differences because they create doubts about the purchase because they worry about whether the garment will match their expectations.

Advanced 3D configurators use fabric physics simulation to create accurate fabric behavior through their simulation capabilities. The system demonstrates three different movement patterns which describe the blazer's motion as the customer changes body positions, the sleeves rest on the shoulders, and the lapels predict postural changes. Layering effects are essential because customers use inner lining selections and pocket style choices to determine how the material will change the garment shape. Realistic lighting together with shadows and reflections creates a depth effect which enables viewers to assess the textures and finish of materials.

Customers gain product confidence by using configurators which deliver high visual accuracy to help them select products. Customers can see exact fabric interactions which guarantee the garment will fit as expected and match their desired style and movement. Brands achieve two advantages through this method because it decreases customer discontent while returns and discontent drive customers to believe in product quality and specialized manufacturing expertise. Realistic 3D modeling enables customers to experience digital content through virtual experiences which creates an authentic shopping experience that duplicates physical blazer trials.

Customization Logic Aligned With Tailoring Rules

Blazer configurators serve as intelligent systems which enforce real-world tailoring rules to work as visual security systems. Every choice a customer makes, from fabric type to lapel style, needs to be feasible within production constraints. Certain fabrics will not allow particular stitching methods while specific cuts and linings have matching buttons and collar types which they can use. The absence of this guidance allows customers to design combinations which manufacturers cannot produce, resulting in production delays and product rework and customer disappointment.

Brands use tailoring rules which they introduce into the configurator system to guide users through design work. The system presents customers with valid option paths which enable them to explore creative possibilities which remain within feasible bounds. Designers can use digital tools to explore design options while matching their work to production boundaries which create a streamlined design process. The solution provides design and production teams with automatic order validation which simplifies their workload by decreasing invalid order handling and feasibility inquiry response requirements.

The configurator functions as a digital tailoring authority which combines online customization freedom with real-world production rules. Customers enjoy a confident, error-free design journey, while brands benefit from reduced operational risk and higher order accuracy. Visual interactivity with rule-based logic ensures that every configuration remains both fashionable and producible which transforms the digital experience into a dependable tool for driving business success.

Fit Visualization and Size Confidence for Customers

Online sales of tailored clothing face major difficulties because customers cannot determine how well items will fit them. The customer who likes the style and fabric will hesitate to buy the blazer because they doubt how it will fit their body. 3D blazer configurators provide users with two advanced features which enable them to see actual-sized models and experience virtual garment trials. Customers can enter their measurements and see how the blazer adapts to their shape, offering immediate feedback on shoulder alignment, sleeve length, and torso fit.

Some advanced configurators enable users to display their own image of the blazer through augmented reality technology which projects the blazer onto their visual field. The system creates a virtual fitting room which simulates real-world fitting experiences. Customers can experiment with different styles, colors, and fit options, seeing exactly how each variation interacts with their body. The system creates transparent processes which establish trust while decreasing customer doubts which leads to faster purchase decisions.

The configurators enable accurate fit simulation which helps to reduce sizing mistakes that result in product returns. The company achieves improved delivery performance through its first-attempt-success rate and customer contentment and reduced need for post-purchase corrections. The digital shopping experience becomes better for users because they can see the actual size of the blazer which helps them make correct buying decisions. The combination of fit visualization and immersive experience helps customers trust the brand more which results in better online sales for customized clothing.

Bridging Online Configuration With Manufacturing Workflows

The 3D blazer configurator provides its best value when it operates in full alignment with production processes. The customer needs to select every design element which includes fabric and cut and lining and buttons and stitching style to create a production design that requires no manual work for manufacturing. The approach of HexaCoders enables direct system connection for configurators to interact with backend systems including ERP and PLM and production scheduling software.

The system automatically transforms all design specifications into data which manufacturing can use for production after the customer completes their design decision. The system generates real-time bills of materials which include cutting patterns and stitching instructions and assembly workflows. The system eliminates manual errors while it speeds up production and maintains uniform product quality for all customer orders. Manufacturers maintain their operational efficiency while they enable fast order processing for large volume orders which lets them handle all requests quickly without errors.

The integrated system provides both operational control and traceable system operations. Production teams understand which items to produce and the sequence of production while design teams observe current trends and user feedback from the configurator. The system creates a digital-to-physical process that operates smoothly to capture and validate customer ideas before creating physical products. The HexaCoders configurators connect virtual customer experiences to real-world manufacturing processes which enable brands to provide personalized blazer services while they cut operational expenses and boost customer satisfaction.

How Blazer Configurators Improve Conversion and Reduce Returns

Blazer configurators directly influence sales performance by giving customers confidence in their choices. Online shoppers have difficulty selecting tailored clothing because they need to experience the fabric and fit through direct contact but they can only see its detailed elements through online images. The 3D blazer configurator enables users to view all elements of the garment through realistic interactive visualizations which display the expected appearance and movement of the clothing. The system allows customers to perform virtual try-on through rotation and zoom functions which help them confirm their fit before making a purchase.

The advantages for brands can be quantified. The design approval process between customers and businesses creates a design approval process which leads to a major drop in return rates. The organization benefits from a decrease in return rates because it decreases logistics expenses and material waste and lightens the workload for customer service personnel. First-attempt delivery success leads to better operational performance while it increases trustworthiness for the brand. A customer-friendly buying process establishes trust which leads customers to return and recommend the business to others. Blazer configurators create a complete customer journey through their visual realism and accurate fit depiction which works together with manufacturing rules to make purchases easier and decrease post-purchase returns.

Data Insights Gained From Customer Configuration Behavior

The blazer configurator system produces valuable data assets for collection through each user operation. The customer selections of fabric and lapel type and lining color and button style reveal their preferences which show regional style trends and fashion forecasting. The aggregated user data helps brands to discover popular options and identify less chosen options while understanding demand patterns across different groups and regions.

The information provides guidance for making business decisions at the corporate level. The system creates precise inventory planning which leads to better fabric sourcing plus production that meets current product needs instead of outdated product needs. Product development teams utilize configuration patterns to create new products which they use to launch new products and limited edition items while discontinuing items that lack performance. Marketing campaigns use customer preference data to create better-targeted marketing messages and personalized product recommendations. The sales tool of the configurator transitions into an analytics tool which provides ongoing product strategy insights for the business through its development. The use of this data enables brands to acquire a business advantage which allows them to create products that meet customer expectations while their operations run at optimal efficiency.

Common Limitations of Generic Apparel Configurator Tools

3D configurators for custom clothing require specialized tools that exceed what standard 3D configurators can deliver. The solutions which people can purchase as standard products design their aesthetic appearance to be visually appealing but their operational performance to deliver authentic fabric simulation and precise fabric behavior modeling. Customers receive distorted product images which lead to their disappointment and product returns and which damage business reputation. The second disadvantage is that production systems remain unconnected to the existing setup. The generic configurators enable users to create designs which either cannot be built or require expensive manufacturing methods, so operators must make design corrections during the production process. The process leads to inefficient operations which result in production delays and higher expenses. Customers face design challenges because the tools lack rule-based guidance, which leads them to select fashion elements that do not match with each other.

HexaCoders creates advanced configurators which bridge existing system deficiencies. Their system combines realistic 3D modeling with accurate fabric simulation and intelligent rule-based validation to create configurations which look real yet can be manufactured. The system connects directly to production systems which use ERP software to transfer all approved designs into manufacturing operations without producing any mistakes. The advanced configurators protect trust while reducing operational risks and delivering exceptional customer service through their capability to fix system flaws.

How Advanced Configurators Support Brand Scalability

The advanced blazer configurators enable brands to expand their operations through their ability to scale. The tools enable global brands to display their products at different locations while they match regional size requirements and material access and design style needs. Customers everywhere experience the same seamless, realistic design interface, ensuring brand consistency.

The organization benefits because configurators improve their internal processes. The system allows instant addition of new fabrics and styles and features, which updates all digital platforms with current information. The system eliminates manual updates and design necessary training systems and design approval processes of the past. The production system enables brands to expand their production capacity because all configurations comply with manufacturing standards which allow automatic configuration processing.

Scalability enables customers to access more products while their service quality and product accuracy stay intact. The business achieves two advantages which include less operational difficulty and speedier market entry. The advanced configurators enable brands to customize their digital content through a systematized method which maintains consistent personalization quality throughout their global operations.

HexaCoders’ Approach to Blazer 3D Configurators

HexaCoders develops blazer configurators to deliver authentic results. The system uses accurate 3D modeling and rule-based customization and backend integration to create a customer interface which shows all actual products. HexaCoders develops operational solutions which protect essential visual elements through their dual development of digital experiences and their capacity to execute operations.

The configurators serve as operational essential tools which marketers use for their business needs. The production system at HexaCoders achieves excellent results through its design connection to production capabilities which enables efficient operational flow and maintains high quality standards for all production runs. The tools provide brands with a permanent digital sales solution which requires no extra operational resources for upcoming business growth. Customers gain exact fit and authentic product visualization, which leads to assured buying, while brands achieve operational success and lower product returns, which results in increased sales. HexaCoders combines technology with design intelligence and practical deployment to create business results which deliver real value.

The Future of Digital Custom Tailoring

Digital customization has become the standard requirement which online fashion retailers must meet. Blazer configurators enable consumers to create and order their own custom-made suits through the most precise design functions available. The integration of AI together with augmented reality and virtual try-on systems will create better user experiences through its ability to match sizes, forecast styles and show 3D visualizations.

The adoption of advanced configurators by brands establishes their role as market leaders who drive innovation throughout the customized clothing industry. Brands achieve above-average customer conversions while reducing product returns and building customer loyalty through their ability to run business operations with high productivity and precise manufacturing processes. 3D configurators will evolve into essential tools which enable customers to explore and design custom clothing while making online purchases. The adoption of advanced configurators by tailoring brands extends beyond technology investment which enables them to establish market trust through precise operations to create sustainable business advantages based on their ability to personalize products and maintain high product standards.

Conclusion: Building Trust and Precision in Online Tailored Clothing

Online tailored blazer sales succeed when customers obtain all necessary information which allows them to make confident purchasing decisions. 3D configurators enable this by transforming guesswork into certainty. The system delivers a flawless experience because it combines all elements which customers need to design online and receive their orders at home.

For tailoring brands, investing in advanced configurators is not just a technology upgrade—it is a strategic move. The system improves trust between customers and businesses while it enhances their operational processes and sustains their ability to compete in the future. Configurators serve as the link which connects digital shopping experiences with traditional craftsmanship because they establish the value of brands based on their capacity to deliver customized products and high-quality goods.