The automotive industry is undergoing a fundamental shift. Vehicles are now sophisticated systems which integrate multiple components including hardware, software, and electronic systems, together with data-driven intelligence. The combination of rising performance demands and increasing product complexity means that conventional testing and monitoring techniques are no longer applicable.

Digital twins have emerged as a critical technology for managing this complexity. The system enables manufacturers and operators to obtain continuous performance information about vehicles and their components through a digital system which mirrors their actual physical counterpart.

The technology of digital twins enables engineers to reach their objectives through continuous performance monitoring which takes place from the vehicle design stage until the last maintenance activity. Digital twins for vehicle performance management bring the following essential advantages which lead to their widespread implementation.

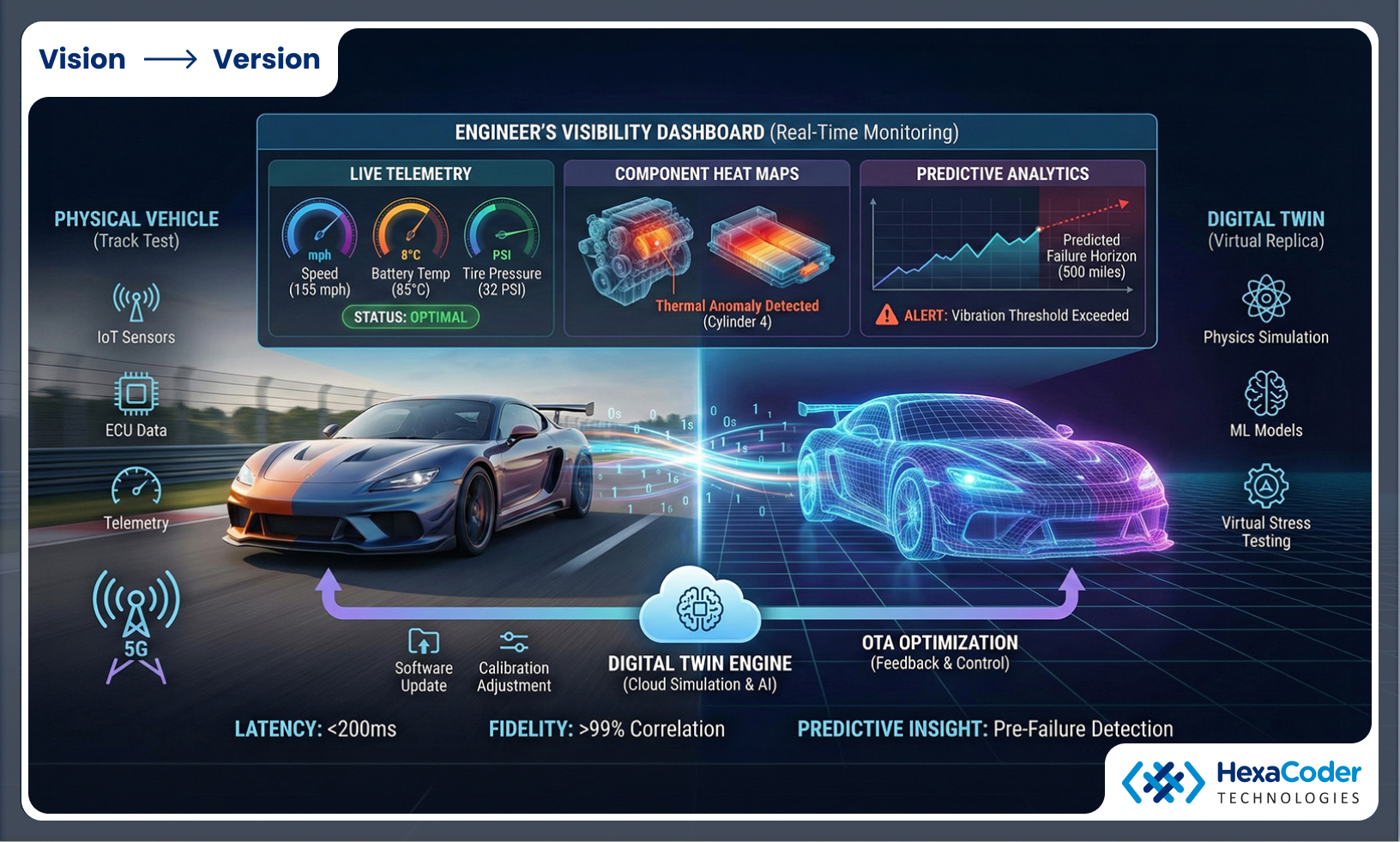

Real-Time Performance Visibility

Real-time vehicle performance monitoring stands as the foremost benefit of digital twins which enables users to observe vehicle operation throughout all operational periods. The system requires scheduled diagnostic tests and regular inspections together with post-incident assessments to monitor vehicle performance. The method restricts present information to its highest level while it creates work delays which extend until corrective measures take place.

The digital twin system gathers data from vehicle sensors and control systems together with their respective operational environments. The system monitors engine output and battery health and thermal behavior and braking performance and suspension response and drivetrain efficiency in real-time operation.

The system provides manufacturers and fleet operators with live vehicle performance information which showcases real-world driving conditions as opposed to testing environments which represent perfect conditions. The system enables users to identify performance deviations which developers anticipated through direct monitoring. Real-time detection of performance deviations allows organizations to take immediate actions while making better decisions.

The operational system requires real-time tracking because it handles mission-critical vehicles which require dependable performance to maintain their operational capabilities.

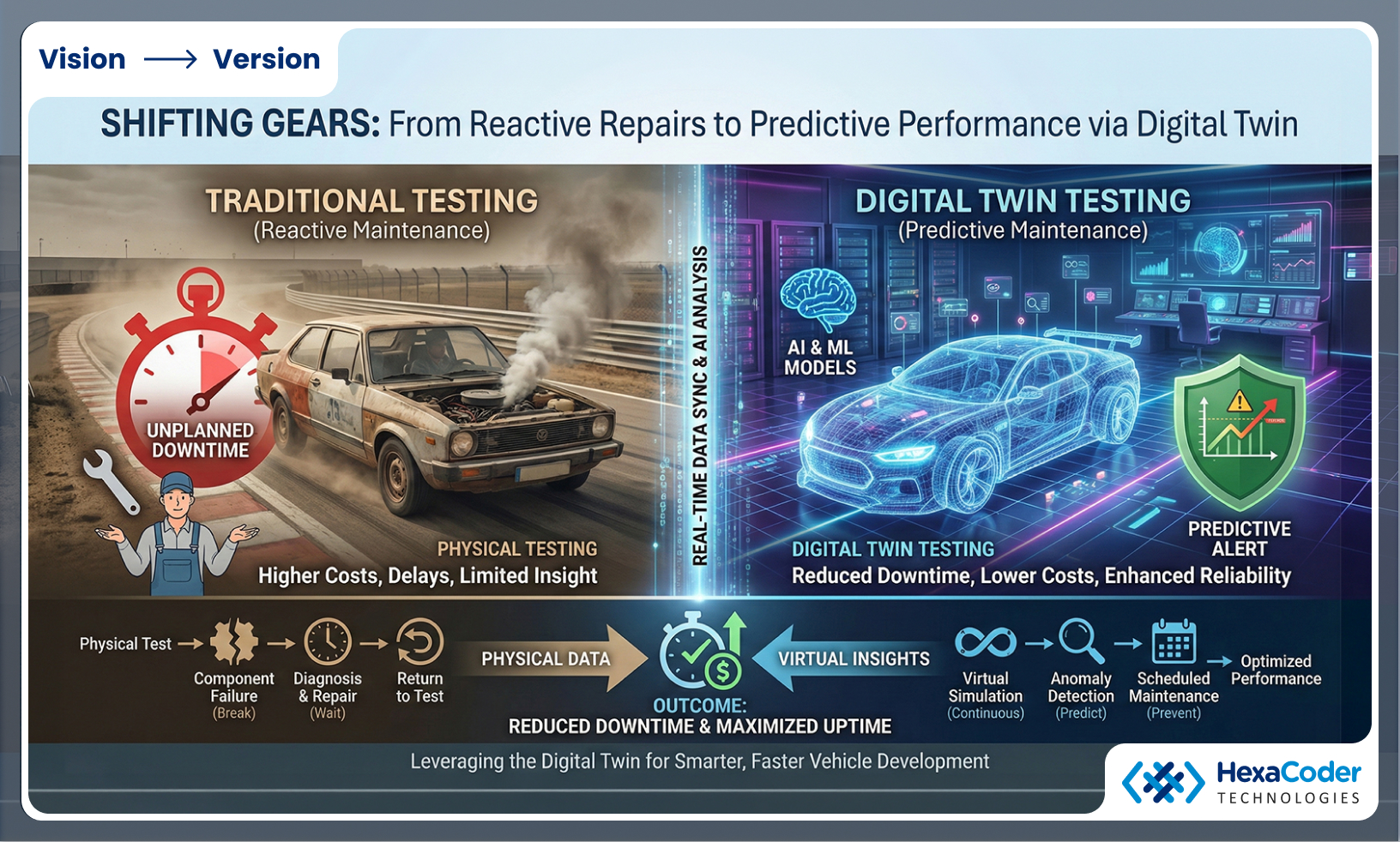

Predictive Maintenance and Reduced Downtime

Vehicle downtime directly impacts revenue, safety, and customer trust—whether it affects individual owners, commercial fleets, or public transport systems. The conventional maintenance method uses scheduled maintenance times and unplanned maintenance tasks which occur after system failures. The maintenance system leads to excessive equipment servicing while generating unexpected operational interruptions.

Digital twins have changed the traditional maintenance system through their ability to enable technicians to conduct predictive maintenance. The system uses digital twins to identify early signs of component failure through direct comparison between real-time vehicle data and existing engineering models and past performance data. Conventional diagnostic methods fail to identify emerging problems which show themselves through minor changes in vibration and temperature and pressure and energy consumption.

Maintenance teams use the predictive system to create maintenance schedules based on future needs. The system delivers actual component status information which technicians use to decide whether to repair or replace components. The approach reduces emergency repairs which leads to fewer unplanned system failures and system components achieving longer operational life through proper maintenance timing.

Fleet operators receive immediate benefits which they can measure. The system enables vehicles to operate for extended periods while maintenance expenses turn into fixed costs and service operations can be synchronized with operational activities. The manufacturers use predictive maintenance to improve their after-sales support system which decreases warranty claims while making products more reliable and enabling data analytics for their service delivery system.

Digital twins have changed the maintenance system through their ability to forecast problems which enables organizations to operate their vehicles at optimal levels with less impact from potential maintenance problems.

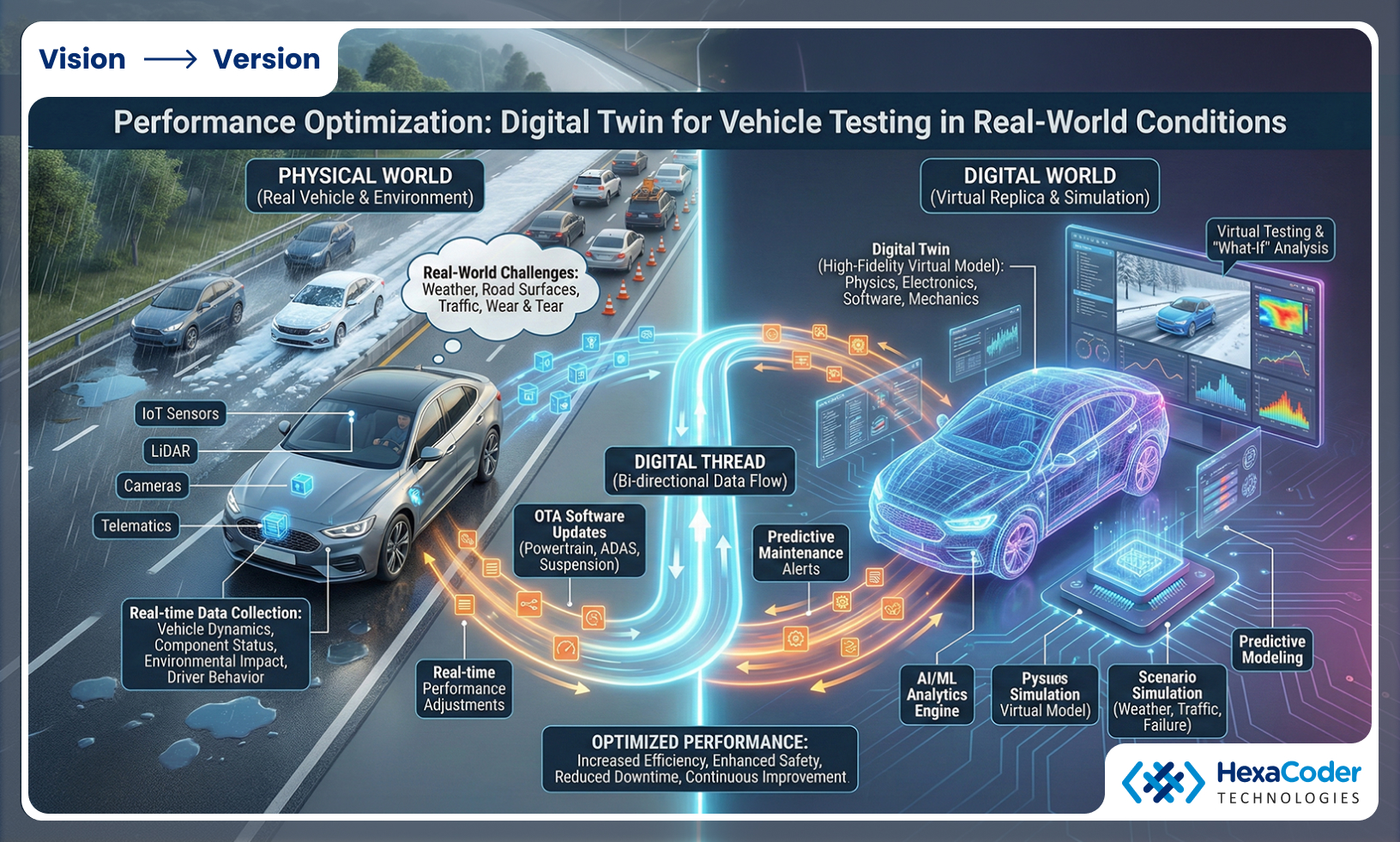

Performance Optimization Under Real-World Conditions

Vehicles operate in actual situations which differ from their ideal testing conditions. The actual performance in real-world conditions gets affected by variations in road conditions, traffic patterns, driver conduct, weather conditions, different types of terrain, and vehicle payloads. The conventional method for performance optimization uses laboratory testing methods together with controlled simulation techniques, which fail to capture the complete range of performance variations.

Digital twins bridge this gap through their ability to maintain current vehicle models by using real-time data from actual vehicle operation. The twin system receives direct sensor input together with control system data and environmental information, enabling manufacturers and operators to track performance changes throughout real-world operations.

Dynamic analysis allows the assessment of engine output and energy consumption along with braking efficiency and suspension response and thermal behavior. Nearly real-time monitoring shows how performance changes with environmental conditions and material degradation and operational usage. The insight obtained from this process enables specific optimization efforts to proceed without requiring any physical design changes.

Digital twins show their highest usefulness in the context of electric and hybrid vehicle systems. They assist in finding optimal points between conflicting goals which include range optimization and performance enhancement and battery lifespan extension and thermal stability maintenance. Energy management strategies get modified through driving patterns and weather conditions and load changes in order to achieve better operational performance and system dependability.

Digital twins create precise performance enhancements which would remain impossible without real-world data verification of optimization activities. Vehicles perform better not just in theory, but where it matters most—on the road.

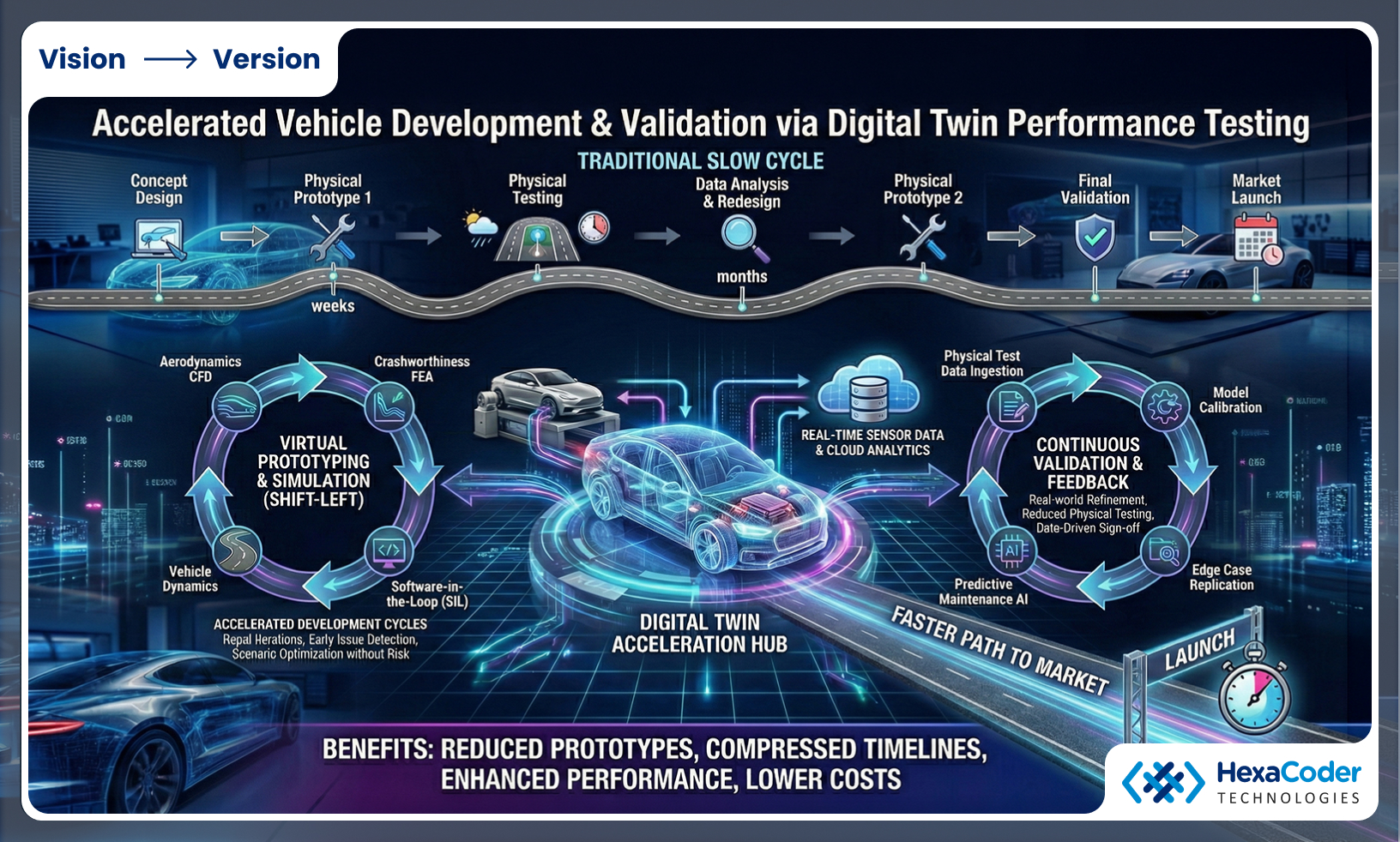

Accelerated Development and Validation Cycles

The vehicle development process must shorten its timelines because of growing performance and safety and regulatory requirements which become more stringent. The process of physical prototyping and testing remains essential for product development yet it incurs high costs and lengthens project timelines while it restricts testing to a limited range of conditions.

The use of digital twins enables organizations to conduct extensive virtual testing which results in faster development and validation processes. Engineers can reproduce vehicle operation through their simulations for all driving conditions. The simulations include both standard operations and extreme environments and edge case scenarios and rare hardware failures which are difficult to replicate through physical methods.

The digital evaluation process enables design assessment before physical prototypes are created. The system now identifies performance overlap areas between different systems which create system failures and potential future issues, resulting in engineers needing fewer design modifications during final project stages, which usually lead to delays and higher product development costs.

Digital twins serve as essential testing tools which increase the effectiveness of physical testing. The digital model receives feedback from actual operations, which enables the system to evolve its simulation modeling capabilities. The system establishes a perpetual validation process that strengthens both digital tests and physical tests through mutual reinforcement.

The manufacturing process becomes faster while design teams gain confidence and development teams experience less risk throughout the development cycle. Vehicle programs develop improved agility which enables teams to swiftly adjust to emerging market needs and regulatory requirements while maintaining their product quality standards.

Improved Safety and Reliability

Vehicle safety requirements remain constant because they need to secure performance from vehicles which have become increasingly complex and now depend on software systems. Traditional safety monitoring methods use fault codes together with scheduled inspections and post-incident analysis methods to restrict their ability to detect potential risks before they occur.

Digital twins enhance safety through their ability to monitor vehicle operation continuously and compare it against predefined performance benchmarks. Subtle anomalies—such as abnormal vibration patterns, thermal stress, braking inconsistencies, or control system drift—can be detected before they escalate into safety-critical failures.

The system enables active safety control to begin when the system has complete visibility of all safety functions. Maintenance, calibration adjustments, or operational changes can be implemented proactively rather than after an incident occurs.

Digital twins function as critical components for both connected vehicle systems and autonomous vehicle systems. The system supports validation work for both sensor fusion systems and control algorithms and decision-making frameworks, which operate in real-world situations. The system continuously detects performance discrepancies, which pose potential safety risks, and takes measures to resolve them.

Manufacturers and operators gain from the continuous performance intelligence provided by digital twins because it transforms their safety management approach from reactive incident handling to ongoing performance monitoring. This transformation leads to the creation of reliable vehicles which consistently meet safety standards in actual driving conditions.

Enhanced Energy Efficiency and Sustainability

Organizations now prioritize energy efficiency because of increasing fuel prices and regulatory obligations and their need to achieve sustainability targets. Traditional energy analysis uses aggregate metrics which make it challenging to detect inefficiencies that occur at subsystem and operational levels.

Digital twins provide detailed information about energy consumption patterns for all vehicle systems. Manufacturers can use real-time data to study how various driving behaviors and route profiles and load conditions and environmental factors affect fuel and energy consumption.

The process reveals inefficiencies which result from component degradation and calibration drift and incomplete operational methods. Digital twins allow organizations to test different operating conditions which lead to ongoing efficiency gains without decreasing system performance or passenger comfort.

The technology holds particular significance for electric vehicles. Digital twins assist in achieving optimal balance between battery life and thermal control and vehicle capabilities which frequently conflict with each other. Optimization decisions rely on data assessment instead of reaching middle ground between requirements.

The method produces cost savings through decreased operational expenses and reduced greenhouse gas emissions and improved sustainability target fulfillment. Energy efficiency transforms into a continuous optimization procedure instead of remaining a fixed design feature.

Lifecycle Performance Management

The performance of vehicles changes throughout their entire duration of use. Components will experience wear while software updates create behavioral changes and operating conditions will differ and user behavior will change. The traditional performance assessment method fails to recognize these operational dynamics.

Digital twins enable organizations to manage performance throughout all vehicle life cycle stages by creating a permanent digital vehicle record that updates with every vehicle movement. The system records and explains all changes which occur during operating time and maintenance service and system adjustments and performance irregularities.

The longitudinal data enables organizations to make better decisions throughout the entire vehicle lifecycle. Manufacturers can enhance their warranty procedures through this method while developing new products and creating better future designs. Operators obtain better understanding about when to replace equipment and how to utilize assets and what resale values are and what their end-of-life strategy should be.

Digital twin data from entire fleet operations generates strong feedback which engineers can use to enhance their product development process. Real-world testing enables design teams to confirm their assumptions about product performance during development.

Digital twins help organizations achieve maximum vehicle value by developing performance standards that extend throughout the entire vehicle lifespan.

Better Alignment Between Engineering and Operations

A common challenge in vehicle programs is the disconnect between engineering assumptions and real-world operation. Test-optimized designs will perform differently when used in actual operating situations.

Digital twins bridge this gap by connecting engineering models directly to operational data. The engineers acquire information about vehicle performance following delivery while operators learn about the technical limits that define performance outcomes.

The shared operational model establishes common ground for teams from different functions which allows them to work together better while eliminating conflicts and solving issues faster.

Digital twins create a consistent foundation for fleet performance measurement which organizations can adapt to their particular needs throughout their entire vehicle performance assessment process.

Data-Driven Product Improvement

Every vehicle digital twin continuously generates high-value operational data across its lifecycle. The data extends beyond essential diagnostic information. The system records all vehicle activities including actual usage patterns and all component functioning under actual conditions and performance changes that happen over time during different operational conditions with varying user activities.

Digital twin data shows specific patterns when researchers conduct extensive data evaluations. Research reveals which parts maintain their performance across time and which parts experience unexpected degradation and which design predictions fail to match actual field conditions. The development team must assess features through their usage frequency and actual value delivery to customers.

The insight allows organizations to enhance their products based on evidence. Manufacturers use data to determine their investment areas based on warranty reports which arrive later and anecdotal comments which do not provide proof and assumptions. The company must choose between redesigning underperforming products or removing them from their product line. The company can enhance high-impact features through standardization and model-wide expansion. Component suppliers will evaluate their performance based on actual outcomes instead of only contract requirements.

Digital twins create quicker pathways for feedback transmission between production and engineering operations. Design teams use field-identifiable problems to create product updates that include material selection and software logic design and calibration process improvements. The continuous learning process boosts product reliability together with operational efficiency and customer satisfaction.

Digital twins turn operational data into organized insights which let them manage vehicle performance proactively instead of just solving problems. The team uses product roadmaps to establish innovation areas that will drive their long-term business growth through measurable performance achievements.

The HexaCoders Framework for Developing Vehicle Digital Twins

HexaCoders develops vehicle digital twin systems with a primary goal of creating solutions that can be used in real-life situations and which will show measurable improvements in system performance. HexaCoders creates digital twins which represent actual vehicle systems through their development of digital twin systems that show actual vehicle systems and business goals and operational performance standards.

Every digital twin system has been designed to combine real-time vehicle data with embedded system operations and engineering models which create an ongoing vehicle performance system for vehicle operations. The system provides actionable intelligence through fault detection and predictive maintenance and performance enhancement and lifecycle monitoring processes instead of offering static dashboards or separate analytical tools.

HexaCoders has established integration as a fundamental component of its operational methodology. The vehicle digital twins provide direct connections to existing systems which include fleet management systems and maintenance planning systems and ERP systems and engineering databases. The system ensures that operational insights move directly into operational workflows without the need for manual processes or data duplication.

Both scalability and usability hold equal importance. HexaCoders develops digital twin systems which can expand their reach across different vehicle types and platforms and global locations while maintaining user-friendly design for engineers and operators and decision-making personnel. The organization operates daily through its regular business functions instead of handling temporary analysis projects.

The real vehicle operations together with actual enterprise processes serve as the foundation for HexaCoders digital twin design process which leads to improved equipment reliability and operational efficiency and equipment uptime and enhanced lifecycle management. Digital twins function as performance tools which provide continuous value to users instead of being experimental technology.

Conclusion

The monitoring process has evolved into performance intelligence through the development of digital twins. Digital twins have brought about a major transformation in vehicle performance management because they established a new method for handling vehicle performance assessment. The traditional testing method uses periodic testing together with static simulations and testing which detects only temporary system faults. The digital twins create a complete vehicle performance model which shows how vehicles operate during their entire operational lifetime.

The system allows manufacturers and operators to track system performance in real-time which helps them identify early problems and improve system performance and handle their assets in a timely manner. The system has shifted from handling maintenance operations which occur after system failures to implementing maintenance procedures that use predictive methods. The system uses actual product performance data to create customer experience improvements which perform better than previous estimates. The system uses contextual data from multiple sources to make precise lifecycle decision-making.

The intelligence layer has become vital for the modern vehicle functions which include electrification features and connectivity capabilities and software-defined architectures and automated systems. Organizations that lack digital twin technologies must handle performance management maneuvers which lead to increased operational expenses because of reliability problems and development time delays.

Digital twins turn vehicles from fixed products into intelligent systems which use data to adapt their functions. The system improves operational safety while achieving better efficiency and environmental performance and customer satisfaction.

Digital twins have become mandatory requirements for organizations which pursue performance excellence over multiple decades because these technologies have evolved from experimental phases to critical operational necessities. The system enables intelligent mobility through its strategic capability which allows continuous performance improvement and risk identification and decision-making based on actual world data instead of past data.