The commercial vehicle industry operates under utterly different sales dynamics compared with consumer automotive markets. Truck purchases are not impulse. They are high-value, specification-heavy decisions that carry the weight of payload requirements, regulatory compliance, operating environments, lifecycle costs, and long-term business performance.

Fleets are diversifying. Customization becomes the rule rather than the exception. Traditional sales tools-static brochures, spreadsheets, and manual configuration processes-will no longer suffice. This is where truck 3d configurators become crucial enablers for commercial sales teams.

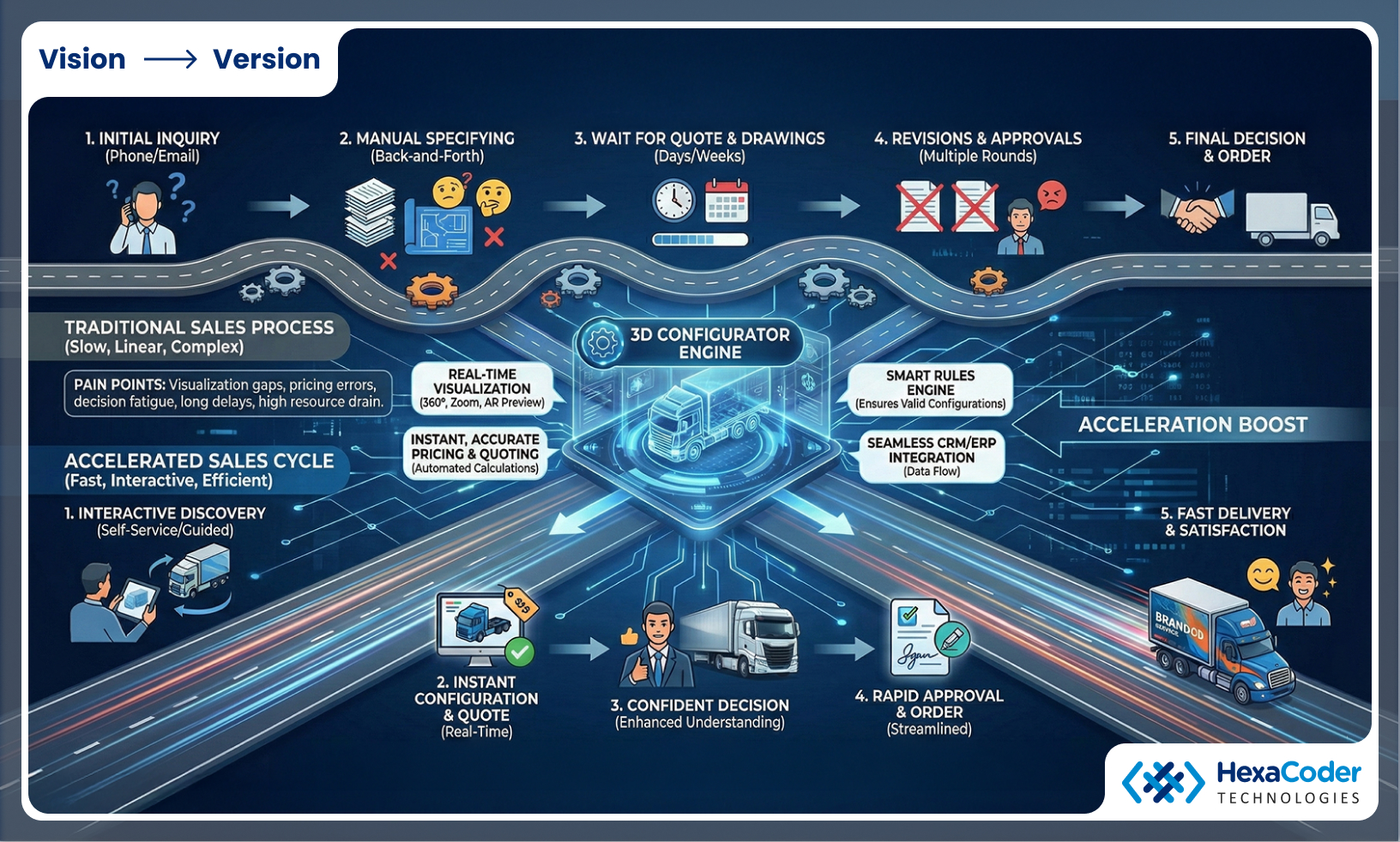

3D configurators are breaking the old practice and redefining how trucks are specified, sold, and delivered with visual realism, rules-based configuration, and system integration. They reduce sales friction and improve decision quality while aligning commercial discussions with operational reality.

Managing Complexity in Commercial Truck Sales

Commercial trucks are not offered in the market as single units; they are sold as systems. Different types of chassis may be ordered together with an axle configuration, a powertrain, compliance to emission control laws, body types, a layout of cabin safety features and telematics, and various regulations enforced in particular regions.

For sales teams, managing this complexity manually introduces risk at every level in the process. Incompatible options for sale, misunderstood requirements, and configuration errors usually surface late: during engineering validation or production, and lead to rework, delays, and unhappy customers.

Truck 3D configurators are built to address this challenge by integrating engineering logic into the sales process. Configuration rules guarantee that only feasible combinations should be selectable. Regulatory constraints, weight limitations, and technical dependencies are enforced automatically.

In fact, the sales team can thus focus on how well they understood the customer needs instead of validating configurations. This brings complicated specifications within reach-even for highly tailored fleet orders.

Enhancing Customer Understanding Through Visual Configuration

Commercial buyers have become ever more complex, yet the technical drawings and specification sheets still open gaps concerning what is to be delivered. Misunderstanding layouts, dimensions, or the placement of components could easily misalign expectations.

A 3D configurator means customers can see the exact thing that they are ordering so there is no room for misunderstanding. As a selection is made, the exterior variants, body configurations, cabin interiors, and functional components can be visualized in real time.

This visual vantage point can be particularly beneficial for atypical use cases-including refrigerated transport, construction, mining, or municipal services-because customers might assess if the configuration supports their operational workflows prior to commitment.

By improving understanding up front, configurators reduce postorder changes and instill buyer confidence in the purchase decision.

Accelerating the Sales Cycle

A single deal may go through several rounds of clarification involving sales, engineering, pricing, and production planning. Every config change may trigger a paradigm of manual checks, updates of drawings, quotes, and internal approvals. The back-and-forth prolongs sales cycles and increases the risk of delays, especially when it comes to competitive bidding.

Truck 3D configurators greatly compress this timeline, validating configurations in real time. As selections are made by a sales team or customers, the configurator immediately applies engineering rules and checks for compatibility and feasibility. Invalid combinations are automatically weeded out, thereby breaking the need for manual validation all over again.

With pricing logic and dependencies between options embedded into the system, quotes can be produced accurately while discussions with the customer are in progress, rather than waiting for many rounds of internal reviews. Sales teams can thereby finalize specifications quickly, respond to tenders efficiently, and push deals ahead with no unnecessary friction.

Speed becomes a decisive variable in commercial sales. LTATs increase the odds of winning for speedy responders, especially when customers are otherwise comparing multiple suppliers. Internally, shortening the sales cycle further eases the burden on engineering and pricing teams, enabling them to put their energies into work that truly adds value.

Configuration conversion to order at a much more rapid rate would mean speedier order booking and cash flow for manufacturers. Closing deals, triggering production planning, and realising revenue-all fast. In the long term, efficiency is converted into a possible competitive advantage in those markets where customisation is expected, but speed is also taken into account.

It would entail reduced variability, bringing within manufacturing a better production planning, inventory management, and quality control. Less unique builds result in a smoother workflow and better resource utilization. Gradually the integration to this would allow scalable growth in fleet-focused commercial sales.

Align Sales with Engineering and Manufacturing

That was where the top dysfunction of commercial vehicle programs existed: the gap between sold and built efficiently. Problems with sales configuration arise late in the workstream-development by engineering review or production planning- which cause delays and costly changes.

Truck 3D configurators close the gap by instituting the engineering logic into sales. Upon completion of a configuration, structured data such as bills of material, option codes, and build parameters can automatically be extracted. All this is constructed from real factory capabilities and constraints.

When integrated with ERP, PLM, and MES systems, configuration data can flow seamlessly into downstream workflows. In effect, less time spent validating sales orders would be spent on innovation and optimization by engineering teams. On the other hand, the production teams would receive clear and unambiguous build instructions fused with real-world processes.

This minimizes rework, reduces production disruptions, and enhances on-time delivery performance. Vehicles will meet customer expectations, and internal teams will experience fewer surprises.

By connecting sales decisions directly to manufacturing execution, 3D configurators transform the sales-to-production pipeline into a coordinated, efficient system rather than a fragmented handoff.

Empowering Dealer and Distributor Networks

Dealers and distributors are critical in commercial truck sales, especially in geographic markets. However, consistent product representation in a distributed network has always been a challenge. Misconceptions based on how people interpret something, have outdated material, or incomplete understanding of what's being sold would create variability and customer dissatisfaction.

Truck 3D configurators provide the dealers with a standardized, manufacturer-controlled sales tool. They can configure compliant vehicles, view available options accurately, and ensure that all configurations conform to engineering and regulatory requirements. The system guides the users through valid choices, lessening dependence on individual expertise.

This is basically reducing reliance on selling through static brochures, PDFs or physical demo units, very expensive to maintain, and often out-of-date. With the configurator itself enforcing rules and consistency, the training requirements are correspondingly reduced.

For the manufacturers, this means stronger brand governance and more predictable results from a sales standpoint. The consistency in presentation of products across markets diminished the risk of faulty orders. The dealer would be a more effective partner, able to give accurate, high-quality sales experiences synchronized with the manufacturer standards.

Reduce Risk of Returns and Post-Delivery Modifications

Of all the errors that are incurred during the configuration stage, those that are detected by the customer after delivery are the most expensive for a commercial truck program, as most fix-it activities, after all, require physical rework, retrofitting components, or extended warranty support to remedy the mismatch of specifications. All these are cost drivers and put a strain on customer relations, especially when dealing with fleet buyers who are usually on a very tight schedule.

The truck 3D configurators mitigate this risk by providing a single validated source of truth across the entire sales-to-production value chain. All participants-customers, sales force, engineering, and production planners-leverage the same rules-based configuration environment to check the feasibility of all selections against engineering, regulatory, and manufacturing constraints before proceeding with an order.

With detailed visualization and digital approval of configurations, the possibility of ambiguity is eliminated at an early stage. Customers know precisely what is being provided for them, and internal teams share a common definition of what was delivered. What goes through is what gets made.

Thus, this alignment improves first-time-right delivery rates by a great measure. Fewer discrepancies leave the factory, and post-delivery surprises seldom occur. Hence, the manufacturers see a lower rate of returns and fewer rework costs, almost negligible on warranty claims.

But the positive effect on customer satisfaction is immense. Deliveries backed by some level of reliability establish trust and facilitate long-term contracts, thereby cementing repeat business. In the brutally competitive commercial vehicle sector, a capability to deliver to promise becomes a salient differentiator and not just a baseline expectation.

Supporting Electric and Alternative Powertrain Trucks

The shift towards electric and fuel cell and hybrid trucks has added a new layer of complexity to commercial vehicle portfolios. Unlike conventional drivetrains, powertrains other than conventional ones introduce tightly coupled dependencies between battery capacity, range, payload, charging infrastructure, thermal management, and regulatory compliance.

Manual management of those dependencies implies higher risks to be taken at every stage of the selling and configuration process. Truck 3D configurators can tackle the problem particularly well. They allow the manufacturer to set sophisticated rule systems to ensure every configuration remains technically feasible and compliant with local regulations.

The customer can compare different powertrain options while observing the real-time impacts on range, payload, charging requirements, and total cost of ownership. This transparency aids decision-making and shields against creating unrealistic expectations that often translate to dissatisfaction down the road.

For the manufacturer, configurators offer a controlled environment for the introduction and scaling of alternative powertrain offerings. They can lead the sales team down valid configuration paths even without in-depth technical expertise in fast-evolving technologies. Engineering teams are shielded from excessive requests for validation from customizers, which, in turn, allows them to focus on innovation and optimization.

The rapid expansion of electric and hydrogen trucks across market segments is being harmonized by the 3D configurators, allowing offerings to be standardized while at the same time enabling flexibility. Striking this balance will give the manufacturers confidence to grow their alternative powertrain portfolio without jeopardizing operational stability or customer experience.

Leveraging Configuration Data for Strategic Insights

Any interaction with 3D configurators generates useful data. Thus, over time, these allow manufacturers to glean the most favored configurations, which options remain rarely selected, and how preferences change with region or industry.

This data translates into enhanced strategic decisions.

Product teams become armed to give pertinent offering a makeover owing to real demand and not mere assumptions. Supply chains are aided in better anticipating component requirements, while sales leadership focuses their go-to-market strategies on well-founded customer preference.

Over time, configurators evolve from sales tools to strategic intelligence platforms for long-term portfolio planning.

Scalability Across Markets and Product Lines

As manufacturers venture into a new market with a new truck model or series, maintaining consistency grows complex.3D configurators offer an expandable and adaptable framework. Regional rules, compliance requirements, and pricing structures can be managed in a centralized manner, yet with enough room for local flexibility.

The addition of new models or variants can take place without rebuilding the entire sales process from scratch. This scalability nurtures growth, while at the same time maintaining control over complexity. HexaCoders are in the making of setting truck 3D configurators for sales environments dedicated to commercial vehicle manufacturers and fleet-focused sale activities.

Rather unlike the conventional visualization tool, HexaCoders' solutions embed within their configuration logic in real engineering, constraints, and workflows of manufacturing and sales. Accuracy, actual integration, and operations' relevancy are to be expected. They lead to integration with enterprise systems, and thus sales configurations are transformed into production-ready data, resulting in a unified sales-to-delivery pipeline taking friction away and improving execution.

By meaningfully aligning configurator applications with real commercial vehicle complexity, HexaCoders enables manufacturers to expand customization without sacrificing efficiency or control.

Conclusion: Strategic Sales Approaches for Commercial Vehicles.

Today, truck 3D configurators are no longer considered as an enhancement to the sales process. Indeed, 3D configurators are strategic needs that meet the increasingly complex markets for commercial vehicles.

Configurations that can increase configuration accuracy, accelerate cycle time in sales, align sales with manufacturing, and create an ecosystem for data computerized decision-making would directly and ultimately affect revenues, margins, and customer satisfaction.

For manufacturers that compete in a market defined by customization, regulation, and operational performance, truck 3D solutions provide a clear competitive advantage. They turn sales from a mere transactional activity into a structured and intelligent process aligning itself with modern realities of commercial vehicle production.

This capability for HexaCoders' clients is not merely about selling trucks; it is about building future-ready scalable ecosystems of commercial sales.