Best Digital Twin Solutions for Steel Manufacturers

The steel industry is all about these three intersections: high scale, precise operations, and operational intensity. Every decision, whether about raw materials handling, blast furnace operations, rolling mills, quality control, or logistics, has implications around cost, safety, and efficiency. Monitoring systems that are mostly computerized generally isolate features, so it is always grievously reactive. Steel manufacturers have begun using digital twin solutions, which allow them to simulate, monitor, or optimize their operations in real time.

In simple terms, a digital twin creates a living digital twin of a physical asset, process, or even an entire plant by connecting sensor data to operational models and analytics. It then gives steel manufacturers unmatched visibility into equipment health, process performance, energy consumption, and production results. This, in turn, results in smarter decision-making, reduced downtime, and improved competitiveness in a highly demanding market.

This blog will discuss the best digital twin solutions available to steel manufacturers, their most important characteristics, and how they support modern steel production processes on a large scale.

Why Digital Twins Matter in Steel Manufacturing

Steel production is a complex continuous process, and sometimes minor inefficiencies can ruin everything. Equipment failure, inconsistent quality, wastage of energy, unexpected unplanned shutdowns, these are perhaps the biggest grievances. Digital twins are always there to help with these things. Digital twins provide a continual, real-time view of operations that are otherwise broken by those traditional dashboards.

Real-time operational data within a physics-based model allows digital twins to reveal the fact how things are happening in the plant operation, but with the added capability of prescribing potential future actions. Manufacturing plants gain a particularly vital advantage from experience-based predictive and prescriptive intelligence, including steel plants, where processes are tightly coupled; disturbances spread quickly.

Digital twins also cover long-term optimization features. They allow trying some process changes, new materials testing, or capacity expansions into the future without interrupting the ongoing production live. As steelmakers adopt initiatives such as automation, sustainability, and Industry 4.0, digital schemes will transform from an optional add-on enhancement into a foundational technology.

HexaCoders Digital Twin Solutions - Specifically Designed for Steel Manufacturing

HexaCoders construct digital twin solutions that are custom-built and specific to the operational realities of the steel industry. Unlike generic platforms that demand heavy customization, HexaCoders invests resources in building digital twins that reflect directly on their process, equipment configurations, and even decision-making workflows of a manufacturer, thereby guaranteeing faster adoption and measurable impact on operations.

Through the combination of production data, sensor inputs, and process logic, HexaCoders digital twins replicate steel manufacturing as accurate and actionable as possible. The twins give real-time views of operations, such as the following: at furnaces, rolling mills, material handling systems, energy consumption, and quality checkpoints. Manufacturers can monitor performance, detect anomalies, and analyze trends all from a single unified interface instead of relying on siloed systems.

One of the major strengths of HexaCoders is its emphasis in practical deployment and enterprise integration. Digital twins are supposed to connect seamlessly with ERP, MES, PLM, and quality management systems. After that, any process simulated or optimized on a digital environment will directly flow into operational systems, guaranteeing continuity from planning to execution. This reduces manual handoffs, accelerates decision-making, and improves operational accuracy.

HexaCoders also prioritizes scalability and adaptability. As production volumes grow or processes evolve, the digital twin evolves alongside the physical plant. This makes the solution suitable for both modernization initiatives and greenfield steel projects. For manufacturers seeking digital twins that deliver tangible operational outcomes rather than theoretical models, HexaCoders provides an implementation-driven approach grounded in real manufacturing constraints.

The Siemens Xcelerator:An End-to-End Digital Twin for Steel Plants

This is one of the broadest digital twin ecosystems available, covering not just steel manufacturing but heavy industry in general. The full lifecycle digital twins offered by Siemens Xcelerator encompass general product design, production processes, and operational performance.

Simulating process scenarios, anticipating the wear of equipment, and optimizing process parameters without the need to risk the physical assets are possible with the detailed digital twin model of furnaces, rolling mills, conveyors, and auxiliary systems created for steel manufacturing.

However, the real strength of Siemens Xcelerator lies in its integration with automation, PLCs, and MES. This allows the digital twins not only to visualize but also to affect operational decisions directly. This means that when steel plants implement Siemens solutions, they can maintain greater control over the consistency of quality, realize reduced downtime, and accomplish energy efficiency improvements at scale.

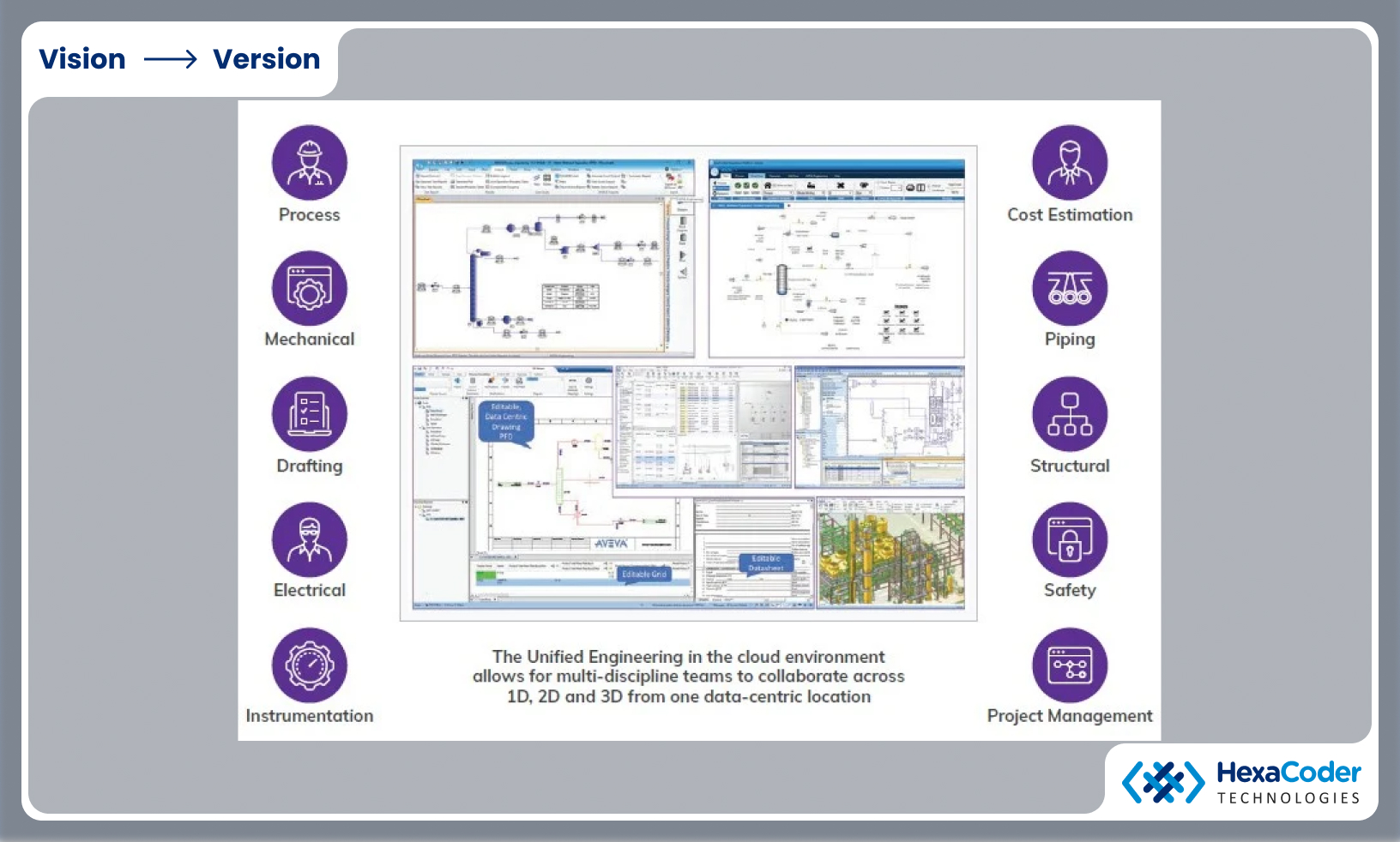

AVEVA Digital Twin: Process Intelligence for Steel Operations

When it comes to process-intensive industries, AVEVA has covered their bases with digital twin solutions, making them a good fit for environments such as steel manufacturing. In steel production, AVEVA focuses on creating operational digital twins that connect engineering data to real-time operations with advanced analytics.

AVEVA digital twins, which apply to steel plants mostly, offer the visibility needed to shed light onto production lines, utilities, and energy systems. Manufacturers in need of process stability and discovering bottlenecks can do so while simulating what-if scenarios. It is very important when we optimize blast furnaces, continuous casting, and rolling operations because stability directly impacts yield and quality.

AVEVA is keen to increase collaboration and decision support. Engineering, operations, and management teams may work from the same digital environment, reducing silos and improving response times. Turning operational data into effective intelligence makes it easier for steel manufacturers to up throughput, improve safety, and increase sustainability while maintaining tight process control.

Dassault Systèmes 3DEXPERIENCE - Virtual Steel Manufacturing at Scale

Dassault System 3DEXPERIENCE platform is perhaps the most sophisticated digital twin environment for large series steel manufacturing today. On top of visualisation, it provides virtual models, high fidelity simulations and full life cycle management in one collaborative space. With this single approach, steel manufacturers with complex plants and interconnected processes can create digital factories that are mirror images of real-world operations in production, maintenance and supply chains.

3DEXPERIENCE's real capability lies in the merging of level digital twins at product, process, and plant levels. At one time for Blast Furnaces, Continuous Casting, Rolling Mills, and Finishing Lines, Steel manufacturers could simulate production flows and visualize the material handling, equipment layout and maintenance strategies. These in-house simulations allow organizations to validate decisions before physical implementation, which saves capital expenditure risks and costly redesign. Changes that previously took months of planning and physical trials can now be digitally tested in a fraction of the time.

Notably for steel production in which grades and yields are influenced directly by material behavior, thermal dynamics, and structural performance, these simulations are sophisticated. Engineers can therefore establish how steel behaves under varying loads, temperatures, and processing conditions, which ultimately ensures product consistency and reduction of defects. Manufacturers validate changes in processes without changes in field scenarios, thus increasing operational reliability, but maintaining the same stringent quality expectations.

The platform is very effective for super large steel companies employing multi-site operations. A central digital twin makes available to leadership teams streamlined standardization of best practices and performance benchmarking across plants, which promotes better coordination of global operations. In addition, 3DEXPERIENCE is positioned as a scalable base for enterprises-operation virtual steel manufacturing for companies with a long view on digital transformation.

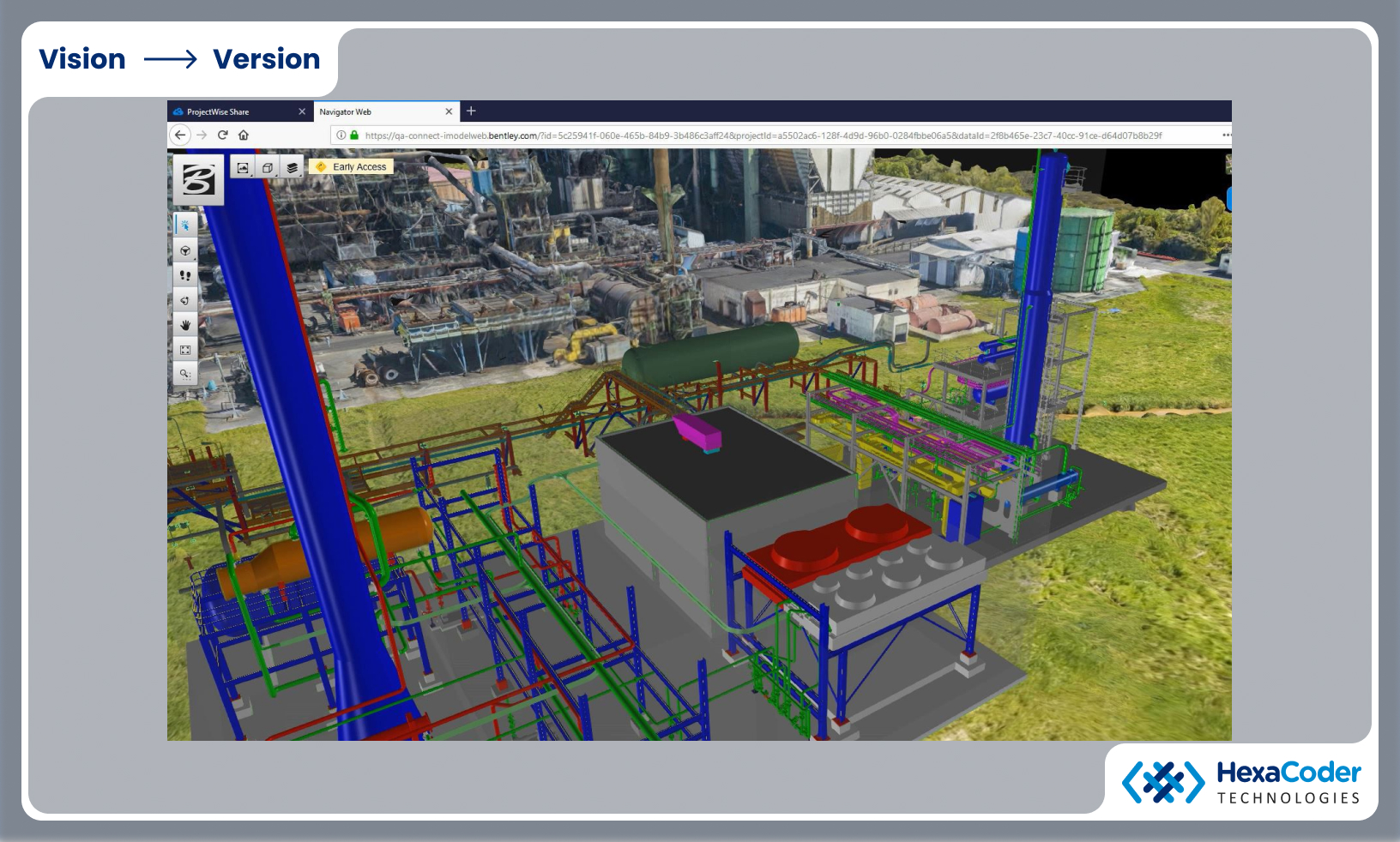

Bentley Systems - Infrastructure and Asset-Focused Digital Twins

Bentley Systems has a distinctly asset-centric approach to digital twins, which makes it very useful for steel manufacturers operating large, asset-intensive facilities. Steel plants depend heavily on long-lived structures, such as furnaces, cranes, conveyors, utilities, and structural systems; and Bentley's digital twin solutions engage in real-time operation-data integration with engineering models to obtain an always updated virtual representation of the status of such assets.

These digital twins enable proactive monitoring of assets and optimization of infrastructure in steel manufacturing environments. Manufacturers gain a real-time view of asset condition and performance trends and maintenance needs. Sensors feed real-time data into the digital twin to facilitate predictive maintenance strategies. These predict failures before they affect production or compromise safety. Such criticality can be illustrated in steel plants, where, without exception, an entire production line may grind to a halt, resulting in direct and consequential financial losses.

Bentley solutions work well over decades to manage an increasingly complex plant infrastructure. Steel facilities typically operate with old equipment and legacy systems. The digital twins of Bentley preserve a living digital record of infrastructure changes, upgrades, and maintenance history. Continuity enables more accurate planning of modernization initiatives, increased lifespan of assets, and prioritization of investments on real performance data as opposed to assumptions.

Another important area of benefit is Bentley's proficiency in managing big spatial data. The steel manufacturers are now able to visualize the whole facility, utilities, and logistics networks in a single digital environment. This lays the ground for better expansion, safety enhancement, and capacity optimization planning. Bentley Systems offers steel manufactures seeking resilience, reliability, and long-term asset performance, a digital twin solution built around the realities of heavy industrial assets.

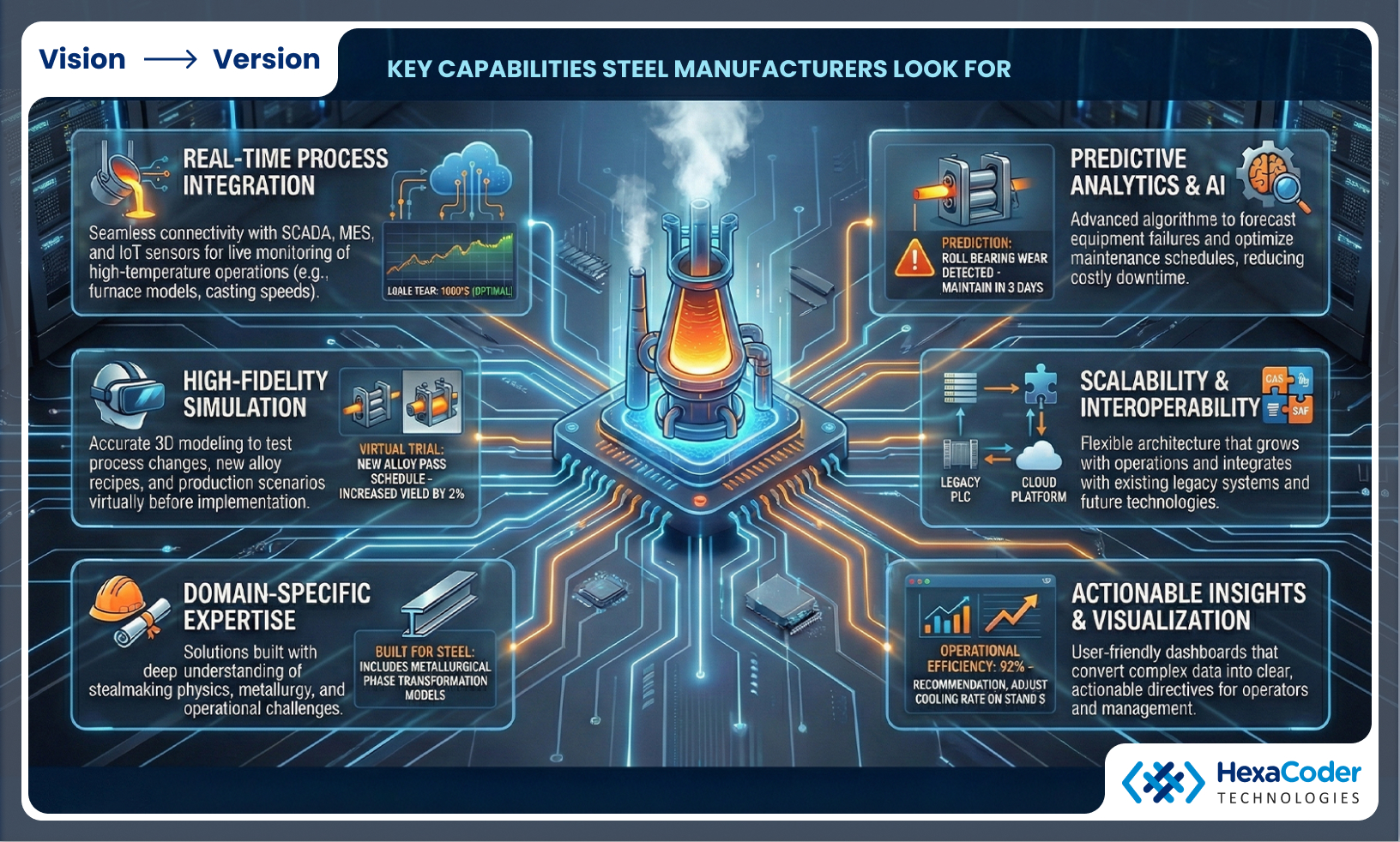

Key Capabilities Steel Manufacturers Should Look For

Selecting the right digital twin solution requires a clear understanding of steel manufacturing complexities. Not all digital twins are built to handle continuous, high-temperature, high-volume industrial environments. Steel manufacturers must prioritize solutions that deliver accuracy, reliability, and seamless integration at scale.

Real-time data integration is fundamental. A digital twin must continuously reflect live operations using sensor data, automation systems, and control platforms. Without accurate synchronization, the twin becomes a static model rather than a decision-support system. Predictive analytics capabilities are equally critical, enabling early detection of equipment degradation, process instability, and quality deviations before they escalate into costly failures.

Simulation and scenario modeling capabilities allow manufacturers to test process changes, maintenance schedules, or capacity adjustments without disrupting live production. This reduces operational risk and supports informed decision-making. Integration with MES, ERP, and maintenance systems ensures that insights generated by the digital twin translate into actionable instructions across the organization.

Scalability and cybersecurity are also non-negotiable. Steel manufacturing operations are large, distributed, and mission-critical. Digital twin platforms must support multi-plant deployments, handle high data volumes, and comply with industrial cybersecurity standards. A solution that aligns with these capabilities becomes a long-term strategic asset rather than a short-term technology experiment.

Key Traits Steel Manufacturers Should Look For

Understanding steel manufacturing complexities must precede the selection of the digital twin solution. Not all digital twins are created for continuous high-temperature hi-volume industry. Steel manufacturers are best served by solutions that feature high-level accuracy and reliability that can integrate seamlessly at scale.

Real-time data integration is crucial. The digital twin must mirror the live operations of the steel mill at all times, using sensor information from automation systems and control platforms. In any case, if it is not actually synchronized, then it is nothing else but a static model and not a decision-support system. Another essential element is predictive analytics. Any degradation of equipment or process instability or deviation in quality must be detected ahead of time through the digital twin and used to avert costly failures in production.

Simulation and scenario modeling empower manufacturers to make changes to the process, maintenance plans, or capacity planning without interrupting the ongoing production process, thereby reducing operational risk and supporting informed decision-making. Integration of the digital twin with MES, ERP, and maintenance systems allows the conversion of the insights generated by the digital twin into actionable instructions throughout the organization.

Scalability and the assurance of appropriate cybersecurity measures do matter here. Steel manufacturing operations are large, distributed, and mission-critical; thus, any digital twin platform must be able to operate in multiple plant environments, ingestion of high data volumes, and adherence to industrial cybersecurity standards. Solutions that demonstrate such capability thereby become a strategic asset for the long term rather than a short-term experiment in technology.

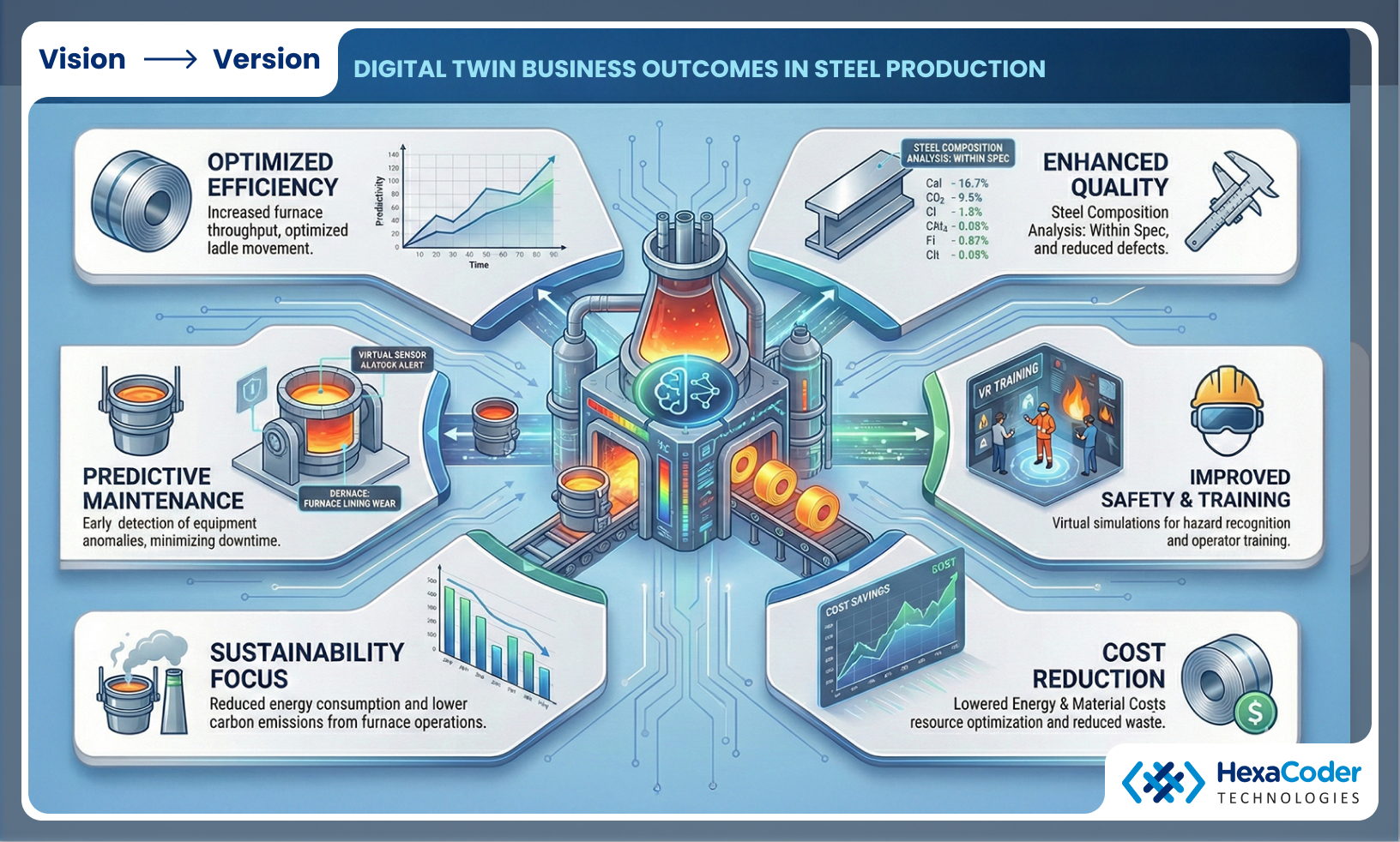

Digital Twin Business Outcomes in Steel Production

Digital twin adoption provides measurable and compounding business value across steel manufacturing operations. Predictive maintenance will help avoid unplanned downtime while identifying equipment issues early on, saving production from stoppage and preserving asset life. Quality control improves as process inconsistencies are detected and corrected in real time, thereby lowering amounts of scrap and rework.

Energy efficiency is another big plus. Digital twins assist manufacturers in optimizing their operations of furnaces, utilities, and energy-intensive processes by analyzing real-time consumption patterns. This in turn means lower operational costs and furthering sustainability objectives by means of emissions and waste reduction. Gains in these areas become strategically important as the industry faces increasing environmental scrutiny.

Furthermore, operational transparency improves top-down decision-making. The executives can view how a plant performs from a system-wide standpoint, thereby improving capacity planning and prioritizing investment opportunities while managing risk. The digital twin provides evidence-based insights-the swift action option-as opposed to late reports, creating a fast lane to effective strategy choice. Most importantly, digital twins transform organizations' cultural paradigms. Steel manufacturers, now ushered into an era of choice, are increasingly driven by the intent of predictive optimization as opposed to ad hoc and reactive problem-solving. Resilience, competitiveness, and adaptability in a rather turbulent global steel market are injected into steelmakers with this refrain.

Conclusion: Digital Twins as Steel Manufacturers' Strategic Advantage

Digital twins are no longer an experimental tool confined to innovation labs; they have quickly turned into a strategic necessity for steelmakers operating in an environment marked by rising production complexity, cost pressures, and global competition. As margins tighten and operational disruptions come at increasing costs, the ability in simulating, predicting, and optimizing processes in real time now provides a deciding edge over competitors.

Today, modern steel manufacturing is characterized by interdependence whereby changes in one area can result in changes in quality, energy efficiency, throughput, and safety across the entire plant. Digital twins lend visibility and contextual intelligence to control this complexity. With living digital duplicates of equipment, processes, and infrastructure, the manufacturer can before implementing a tested decision lessen risk and increase confidence at every operating level.

From an asset scale to multi-plant deployment, the leading digital twin solutions viz. Siemens, AVEVA, Dassault Systèmes, Bentley, and HexaCoders have different strengths. The choice for the right solution would depend on a manufacturer's operational maturity, system landscape, and long-term digital transformation goals. While big platforms give you a lot of breadth and standardization, purpose-built digital twins adapted for steel operations are often faster towards return and far more in-line with real-world constraints.

For steelmakers committed to operational excellence, digital twins do vastly more than facilitate visualization and monitoring. They become the tools for predictive maintenance, process optimization, energy efficiency, and data-driven strategic planning. Most importantly, they evolve organizations away from reactive problems to proactive optimization.

Going into the future, digital twins will create sound foundations upon which resilient, efficient, and future-ready manufacturing operations shall be built. Investing in them today is not merely an adoption of new technology but rather a paradigm shift defining the very essence of how steel is produced, supervised, and optimized as a generational-defining pathway to sustainability.