Why Digital Twins Lead to Smarter Decisions?

Introduction: From React to Intelligent Decision-making

The digital world creates a fairly complicated decision-making scenario. Nowadays, businesses operate in interconnected systems with uncertain market conditions, rich data, and minor inefficiencies that can result in losses of significant amounts. Conventional models for decision-making using previous, assumptive, or static report data no longer suffice; they delay action and lack visibility of what actually happens in real-time. Organizations, on the path towards agility and resilience, have turned to digital twins to ensure that decisions are indeed smarter, faster, and more confidently made.

A digital twin creates a real-time digital version of a physical asset, system, or process. By ongoing synchronization with live data, it allows an organization to have a dynamic view of operations and performances. This capability makes it possible for decision-makers to move beyond the hindsight and intuition of earlier times to prediction and proaction.

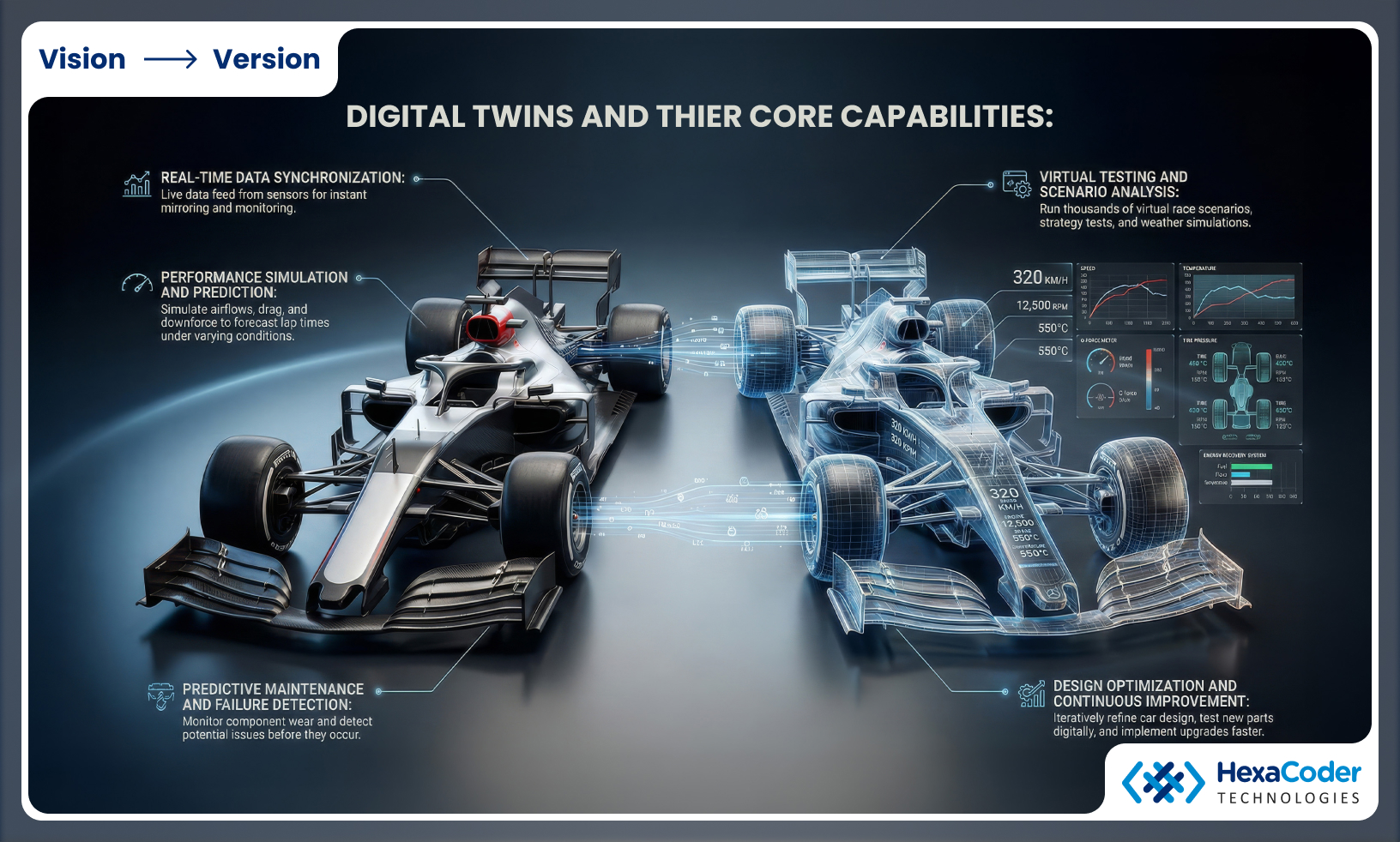

Digital Twins and Their Core Capabilities, Understanding Digital Twins

Digital twins are much more advanced than their static 3D models or one-off simulations. These are dynamic digital representations of physical assets, systems, or processes that evolve synchronously with their real-world counterparts. Digital twins use data from sensors, IoT devices, enterprise platforms, and operational systems to provide continuous and in-time actual conditions, allowing the organization to monitor performance, observe changes, and examine system behavior in real-time rather than by using historical ways or fragmented sources of information.

What really makes digital twins different from traditional analytics or monitoring tools is the fact that they bring data, visualization, and the operating logic all together into one interactive environment. Instead of looking at isolated metrics across multiple dashboards, decision-makers will be able to experience entire systems in the context of with how components interact, understand dependencies, and witness how changes in one area influence outcomes across the broader ecosystem. This visibility at a system level becomes particularly important in complex environments where many variables must be considered simultaneously in a decision.

Digital twins allow the contextual real-time insight beyond abstract data points for much more intelligent and strategic decision-making. Organizations are thus left with a living source of truth for operational, tactical, and strategic enterprise-wide decisions.

Turning Complex Data into Actionable Intelligence

Today's enterprises produce huge volumes of data connected with devices, applications, and operational systems. Pure data, however, do not transform into smart decisions. With the right context, definition, and interpretation, they can flood a team with noise instead, leading to confusion or wrong conclusions. Digital twins address the problem of turning all that raw, disparate data into structured, visual intelligence that aligns directly with real-world systems.

Digital content makes information from a digital model or replica of a physical asset or process intuitive and actionable. Performance metrics, operational conditions, and usage patterns become understandable within a realistic model that allows decision makers to grasp what is happening, as well as what it is happening for. This contextual clarity helps teams identify trends uncover hidden relationships, discover gaps in performance that conventional dashboards or reports would often overlook.

Since insights are genuinely derived from real-time operational data, decisions have been strengthened by evidence rather than assumptions. Teams will be able to result in faster responses, organize issues more appropriately, and focus more on actions that will be meaningfully affecting outcomes. Digital twin setups serve as an intelligence layer that converts the collection of data into decision execution. Hence, organizations are enabled to turn complex realities into simplicity.

Scenario Simulation and Predictive Decision-Making

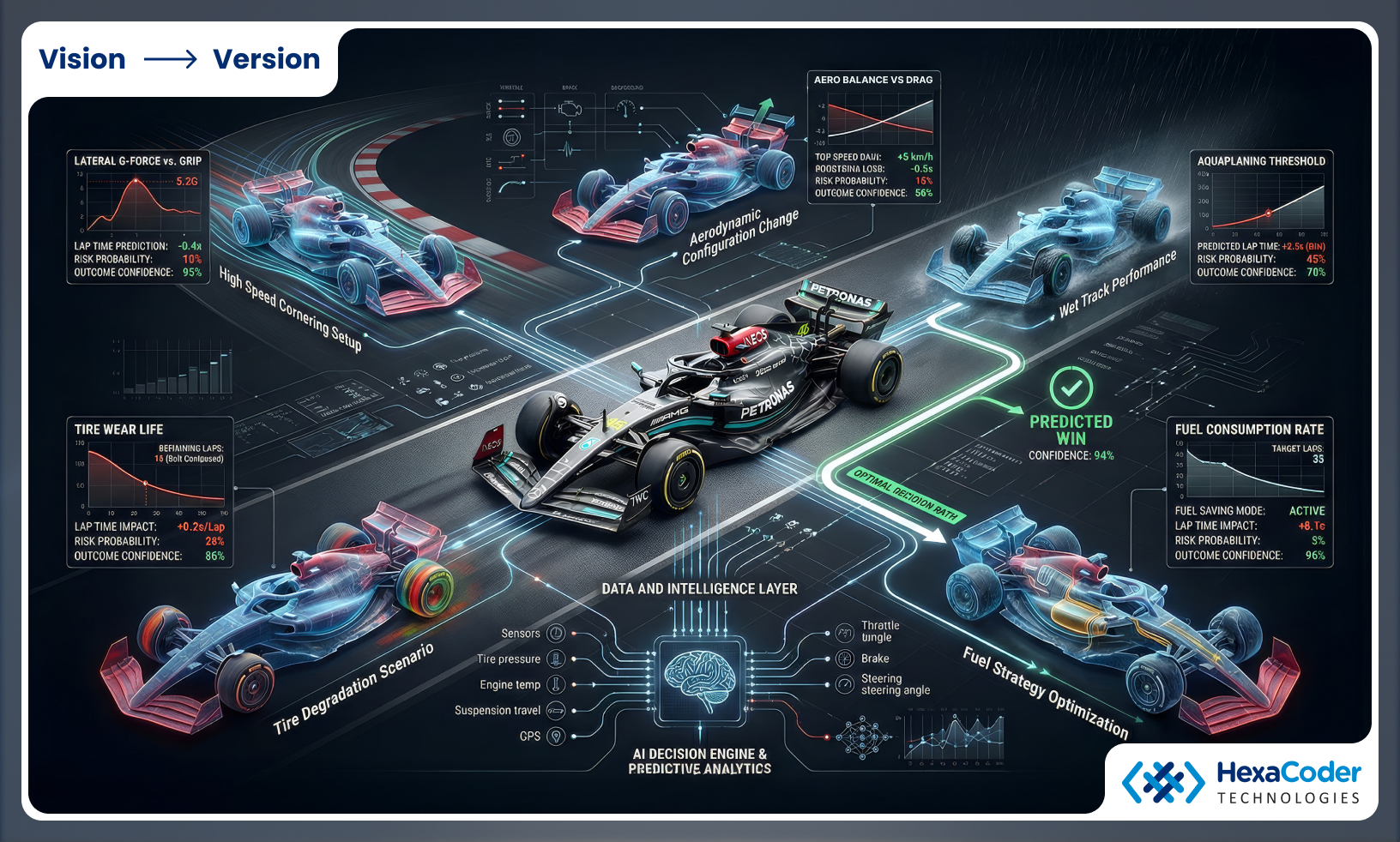

Digital twins create what is probably the most significant benefit: scenario simulation and predictive decision-making. Companies can create virtual environments in which they experiment with "what if" scenarios regarding decisions without making any real-life implementation. Modifying operations, adjusting systems, planning infrastructure, or making adjustments in the event of unexpected disruptions can all be tested in this fashion. Since the risk is none involved in a digital setting, businesses can experiment without the costly mistakes that might accompany a failed trial in reality.

From reactive to proactive, it alters fundamentally the decision-making. Instead of reacting to a failure when it occurs, one can be prepared for future problems, explore different ways to respond, and choose the best way to proceed ahead of time. This empowers teams to evaluate results under different scenarios, develop better understanding of trade-offs, and quantify risks better.

Instead, decisions from digital twins ensure that organizations will not react immediately but plan ahead for future objectives instead of short-term quick fixes. The decision-making becomes more resilient, based on evidence, and strategic. This enables the gradual evolution of uncertainty into improved planning precision, coupled with greater organizational dexterity in response to change.

Driving Operational Excellence in Manufacturing and Industrial Systems

Driving smarter operational choices in manufacturing and industrial environments-high-value areas where efficiency, reliability, and precision matter most-is the role that digital twins play. By creating real-time digital replicas of machines, production lines, and whole facilities, an organization can continuously observe performance and conditions for continued effectiveness.

Fewer delays and failures will occur in reporting critical anomalies because metrics can be monitored and inefficiencies discovered in time. Digital twins are critical in predictive maintenance by analyzing performance patterns and predicting future failure. Hence, there is advance scheduling of maintenance and reduced downtime, both planned and unplanned, while extending the useful life of assets.

Digital twins enable manufacturers to optimize workflows; balance production loads; and improve their quality controls with real-time process behavior visibility on operations beyond maintenance. Decisions that were formerly reliant on delays in reports and manual inspections can now be taken instantaneously through the use of live operational data. This immediacy translates into faster resolution of issues, lower costs of operation, and greater resilience. These capabilities will enable the organization to excel in a world of operational excellence through continuous improvement as manufacturing environments become increasingly complex and data driven.

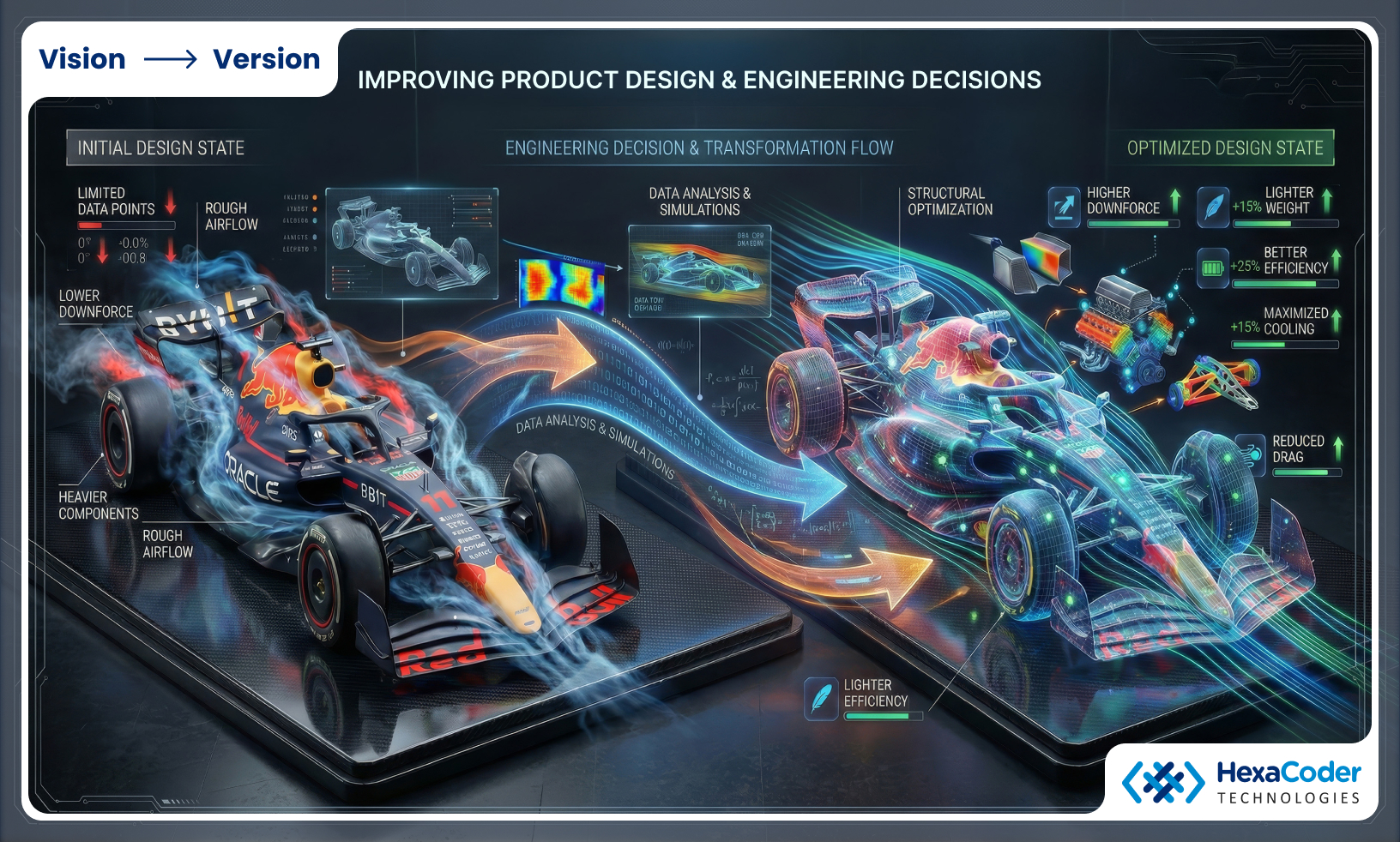

Improving Product Design and Engineering Decisions

Digital twins have been enabling smarter product design and engineering decisions by enabling teams to run tests, validations, and refinements of products in a virtual environment before they exist physically. Engineering teams can now experiment with portrayel realistic operating conditions using a digital twin instead of relying much entirely on several physical prototypes that take time and cost money.

Simultaneous testing of variables, including load, temperature, stress, wear, and user interaction, will provide a more accurate view for engineers of how the product will perform in different scenarios. This fundamentally changes the manner in which design decisions are made. Early in the development cycle, possible weaknesses in a design, limitations imposed by materials, or bottlenecks in performance can be identified at a stage when changes can still be made easily and at low cost.

Engineers would easily identify and compare various design alternatives objectively using data for justifying as well as understanding the trade-offs between costs, durability, efficiency, and performance. Hence, decisions will neither be based on isolated tests nor theoretical calculations but on continuous simulation with real operational data backing it. Digital twins contribute to getting ideas off the ground faster and into the customer lifecycle while reducing risk.

Digital twins accelerate innovation, as iterations that had previously taken weeks can now be assessed over hours. The team can be freer to experiment with unconventional ideas and refine products far quicker without increased development risk. The market launch speed is improved while the shopping basket of product quality increases. Therefore, products arrive with greater reliability and improved real-world performance through digital twins by ensuring that engineering decisions are data, not guesswork-influenced.

Encouraging Higher Intelligence in Infrastructure and Built Environment Planning

Infrastructure and built environment planning typically require long-term investments, with multiple dependencies and effects of high consequences. Digital twins capture this complexity by providing an integrated, data-rich view of buildings, facilities, and urban systems as long-lived phenomena. Digital twin systems combine structural models with sensor data, energy usage, maintenance records, and occupancy patterns to form an intelligent projection of actual infrastructure.

This holistic visibility empowers planners, architects, and facility managers to make informed choices before changes are made: energy consumption scenarios can be simulated to evaluate sustainability initiatives, while space utilization models expose use inefficiencies that are otherwise not detectable through traditional reporting. Maintenance strategies can be very much improved by predicting asset degradation instead of adhering to fixed schedules and hence minimizing the risk of unexpected failures and revenue losses in operations.

Digital twins also foster improved collaboration among stakeholders, as designers, operators, and decision-makers work from a common source of truth; thus, misalignments between planning and execution diminish. In very large-scale projects, this is particularly significant, as decisions made in design can affect operational costs for decades.

Over the life of the asset, digital twins evolve into continuous management tools. From early designs and building through everyday operations to future upgrade requirements, decision-makers will continually have insights into asset performance. This intelligence feeds towards lowering operational costs, increasing energy efficiency, and creating more resilient structures. Furthermore, digital twins facilitate more intelligent and sustainable planning choices that consider not only economic performance but environmental and human considerations as well.

Boosting Customer-Centric and Market Choices

Digital twins become more critical in customer-centric and market decision making with tangible, real-world insights into how customers engage and use the products and services. Integrating usage data, performance metrics, and behavioral patterns allows organizations to advance from mere assumptions and, instead, be factual about what customers require.

Rather than relying solely on surveys or after-launch feedback, companies can see firsthand how products are used among different environments and contexts. Digital twins shed light on features that add value, where bottlenecks occur, and how performance impacts customer satisfaction. As a result, more narrowly defined decision making occurs around feature prioritization, product improvement, and service enhancements.

More proactive, too, are customer-centric decisions. They can now predict how any changes made regarding design, pricing, or functionality may affect user behavior before actually making the changes available to all customers. It lower the risk of misalignment with the market and allows teams to modify offerings based on evidence as opposed to pure intuition.

In this way, that data-driven understanding builds and strengthens over time personalization strategies. Products and services could, understanding real use patterns, adapt to better serve customer segments, providing more personalized experiences. This means better satisfaction, reduced churn, and increased loyalty over time. Thus, digital twins help organizations shift from reactive customer management to continuous, insight-led market decision-making.

Strategic Decision Making and Enterprise-Level Views.

At the enterprise level, more fragmented data are created; departments are siloed; and, visible performance gets delayed. Digital twins resolve this challenge by giving all the operations, financials, and performance data in one dynamic place. Hence, it wouldn't be isolated reports from teams: leadership would access an instantaneous view of the health of the organization and the dependencies of systems worldwide.

Therefore, this perspective enables executives to know how strategic decisions ripple across the business. A change in production can be evaluated with changes in supply chains, infrastructures, or customer experience, rather than isolatedly. Cost, efficiency, risk, performance, then, trade off in terms of short-term outcomes to be balanced with long-term objectives. A strategic initiative is executed more easily under enterprise-wide goals because it has become visible before execution.

At the C-suite level, scenario planning becomes another critical additional benefit. Digital twins allow executives to simulate market shifts, policy changes, capacity expansions, or major investments in the company without subjecting it to real-world risk. Here, the leaders compare various strategic paths, examining possible disruptors and ultimately choosing the most resilient option according to forecasted outcomes. What this does is switch enterprise decision-making from being passive and reactive to proactive and predictive.

Grounding strategic choices in real data and predictive insights, digital twins thus lower uncertainty and enforce accountability. Moving away from intuitive choices, leadership teams now rely on data-based strategies, which tend to have a dynamic and future-oriented approach. This capability gradually strengthens the organization in terms of resilience, capital allocation, and, more importantly, sustainable growth in complex business environments that change fast.

In Conclusion: The Digital Twins Foundation of Decision Making

Digital twins have moved beyond experimental or niche applications to actually be foundational tools for intelligent decision-making. These enable organizations to design actionable insight from the complex and high-volume data that assist in making confident and timely decisions across various industries and functions. Consolidation of data, visualization, and logic in a living digital environment brings clarity where traditional tools would fail.

Digital twins substitute evidential proof for guesswork-from operational optimization and engineering validation to customer experience enhancement and business strategy development. Using predictive capability, teams no longer rely on static reports or delayed metrics; they now operate on the grounds of real-time visibility. They are especially relevant in fast-changing and ever-more complex environments, where things get uncertain.

Digital twins create alignment across organizations as well. Working off one accurate representation of reality makes collaboration smoother and decision-making more consistent across the board. This allows better scoping for strategic initiatives, early risk identification, and proper resource allocation.

As artificial intelligence, IoT, and advanced analytics continue to grow rapidly, digital twins themselves are poised to become more intelligent and powerful. Organizations adopting digital twins today will find themselves getting ready, not just for operational improvements, but for an adaptable and resilient future. Digital twins will become the core decision engine of data-driven enterprises of tomorrow-and goes ahead to champion well informed choices at every layer in the organization.

.jpg)