Introduction

“When a windmill breaks, it doesn't just stop turning, rather it stops earning”. A single windmill failure can cost about $50,000 in lost energy repairs and missed contract in just one day.

That is the cold and expensive truth facing every manufacturer and energy company today. Each turbine is an example of engineering yet most operate like farmhouses. They are checked only when they limp, repaired only after they fail and this results in wasted money, time and energy.

But there's a better way.

This is called Digital Twin. A digital twin is the living, breathing double of your windmill. It is a virtual replica connected by IOT sensors trained by AI manufacturing and sharpened by the logic of industry 4.0.

While your turbine spins in the field, its twin will run in the cloud. Every form, wind and blade that rotates is mirrored in real life. The twin learns, predicts and warns you before damage takes place.

This is the industry 4.0 in action. Machines no longer fall in silence because heavy malfunction inefficiency is visible measurable and can be fixed before it affects production.

The result can be higher up time, longer life for machine and million saved in operational costs.

If you ignore digital twins today, it is like ignoring electricity in 1900. Your competitors will see the future before you even realize the opportunity exists because the future of windmills is not wind and blades, it is data, insight and twins.

The Problem: Windmills Aren't Making You Enough Money.

Let's be honest, most windmills are cash machines in disguise. You have turbines, they can spin, generate energy so definitely they should generate revenue. But guess what? The gearboxes fail, blades have dents on and every breakdown is money slipping through your fingers.

Here's the thing: most maintenance is reactive. Inspections that are being scared with regular checks and hoping nothing breaks down is the reality for almost all energy firms.

Up to 30% of operational cost disappears into unnecessary maintenance and when the turbine actually fails, it causes loss of contract and very angry customers.

Managing huge machines across large farms without intelligence can be likened to running a formula one team with rear view mirrors only. Every minute of ignorance costs you a fortune.

Now that the future is here, Industrial 4.0 is not just a random trend, it is a battlefield. IOT, AI in manufacturing and smart factory are not optional upgrades.

They are what differentiate you from leading the market and struggling to catch up.

Windmills are engineered to be perfect while your operations are not. Until you connect the machine to its brain, you will continually lose profit, efficiency and innovation.

The Breakthrough: Digital Twin Technology

To be honest, guessing is quite expensive. A windmill spins, hums and looks perfectly fine but inside, stress build up, components become weak and the performance rate drops. You won't see that once and you cannot predict it and that is where digital twin comes in.

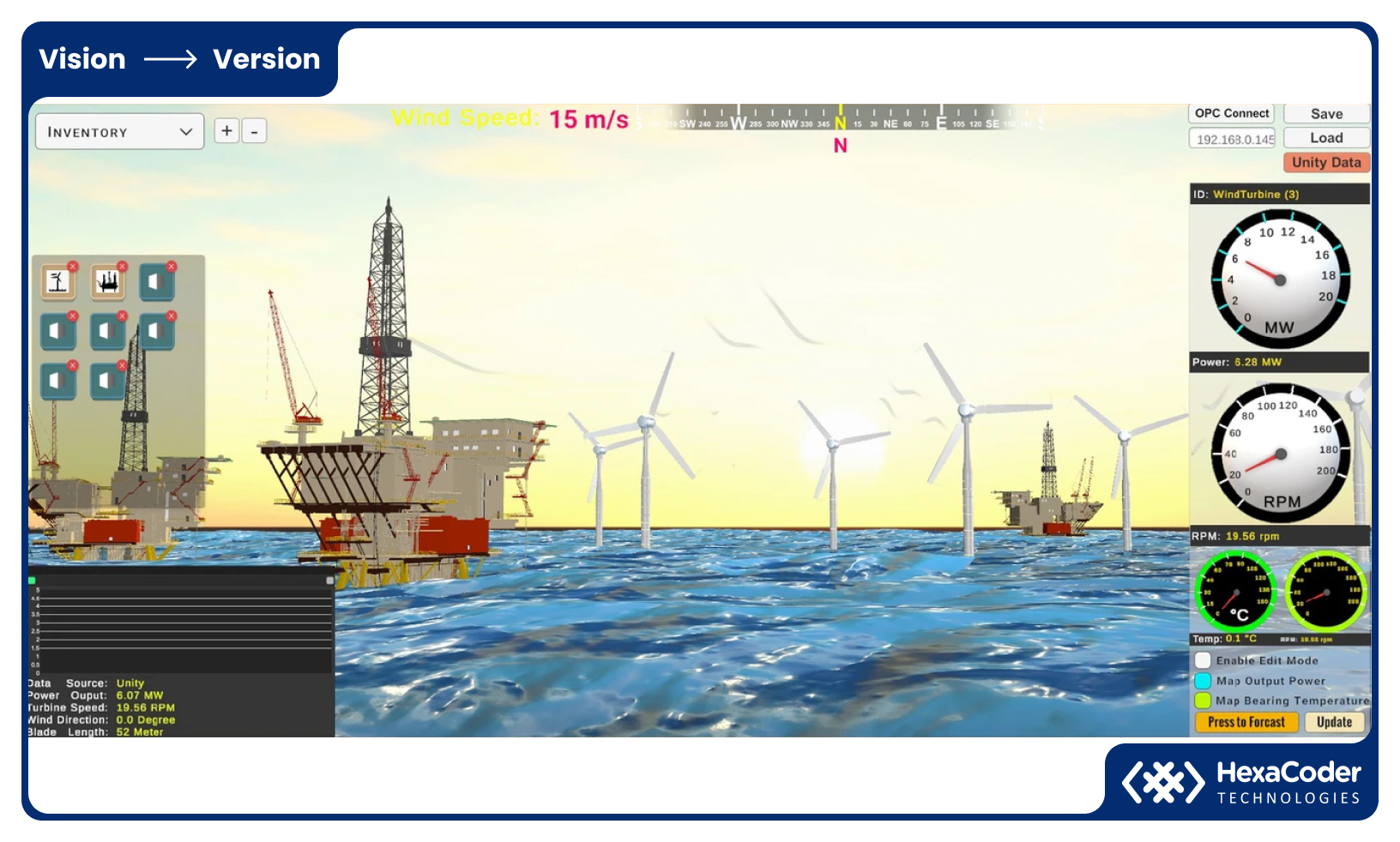

A digital twin is not just a software, report or a dashboard you glance at once in a week rather it's a live virtual replica of every turbine that is synced to IOT sensors and is powered by AI manufacturing and continuously updated in the cloud. Every rotation vibration and gust of wind is tracked, analyzed and interpreted.

These are practical examples of how it works:

- Predictive maintenance:

The twins detect issues before they become failures. It replicate parts before breakdown so downtown is no longer a surprise it is managed.

- Performance optimization:

In reality, analysis shows where turbines do not function properly. Adjustments can then be made immediately which increases the energy inputs and also makes the cost drop.

- Data driven decision:

Every maintenance and operational decision comes with measurable insight. ROI isn't theoretical, it is tracked in reality.

And this is just the beginning. In industry 4.0, every digital twin connects to a wider ecosystem which is smart factories, supply chains, predictive logistics. Your windmill can no longer be a standalone asset; rather it's part of the networked intelligence system that constantly learns, proves and saves your money.

Companies that adopt digital twins will now overperform than their competitors while those who wait will watch profit slide while others capture market share.

So the twin isn't an option now, it is what differentiates your windmill from operating in the past and leading in the future.

Digital Twins and Industry 4.0: The New Standard

This is the reality: induction 4.0 is not coming, it is already here and digital twins are what makes it better.

Factories are no longer isolated islands from machines, they are connected ecosystems where every asset talk, every process feeds data and every decision can be made immediately. IOT sensors, AI manufacturing and analytics allows operators to monitor and control windmills and factories like never before.

The star twins transform ordinary machines into smart assets. They work with other systems like logistics, energy management, maintenance scheduling to create an environment that can be predicted automated and works efficiently. The results are fewer failures, higher throughout and measurable cost of savings.

Consider the population: companies using digital twins reports up to 20 to 30% reduction in maintenance costs and also significant increase in uptime. The competitive advantage is not a mistake. Every turbine components and blade that is digitally tracked and optimized adds more value, revenue , reliability and efficiency.

Industry 4.0 is a battlefield and those who leverage digital twins are armed with data predictive insight and operational intelligence while those who ignore it remain vulnerable to uncertainty, inefficiency and continuous loss of profit.

Digital twins are not accessories, they are the backbones of modern manufacturing. They make your operations fast, smart and profitable. Any industrial engineer, CTO or supply chain manager who underestimates their value is leaving millions on the table.

How Digital Twin Technologies Power Smart Manufacturing.

Digital twins command, optimize and transform, they are not limited to just observing.

Traditional maintenance waits for machines to feel, while digital twins wait for failure before they happen. Every sensor vibration and gust of wind fit AI driven analysis which reveals patterns that are not visible to the eyes. The results are downtime drops, output rises and resources are used exactly where they are needed.

Scalability is when digital twins shine. One twin is powerful; 100 working together creates a network intelligence system. Decisions are not made alone, they affect all production lines, supply chains and maintenance schedules. Even external factors like energy demand rise, weather changes are factored in so that systems are just automatically.

Cost effect isn't hypothetical to companies who has leveraged digital twins as reported over 20 to 40% reduction in unplanned maintenance, fewer replacements and higher overall equipment functionality.

Every dollar invested translates into measurable ROI.

Digital Twins also accelerates innovation. Engineers can stimulate new configurations, test adjustments virtually and also implement improvement with zero risk to uptime or revenue. The factory moves faster, safer and smarter.

The bottom line is that smart manufacturing powered by digital twins is not the future vision, it is already happening. Companies adopting it operate faster and more intelligently and competitors who stick to outdated methods are left to pay for the ineffectiveness.

Digital twins transform windmills into intelligent assets as they make factories predict, work effectively and also bring profit.

Every operation becomes measurable, decisions become smarter and every competitor that would delay adoption loses ground.

The Competitive Advantage of Digital Twins

To be very direct companies using digital twins win.

Every windmill blade and gearbox that is digitally tract becomes an asset that generates revenue instead of being a potential liability. Downtime shrinks and maintenance costs drop drastically. Energy outputs also climbs and every decision is backed up by data not guessing.

Digital twins turns ordinary operations into a strategic weapons that allows you to do the following:

- Predict the problems for the happen which will help to stop failures before they stop your profit.

- Minimize resources instantly and also allocate energy labor and materials with precision.

- Skill intelligently with hundreds of machine one control system and zero waste efforts.

- Innovate safety by testing modifications virtually and also implements improvement without risking production rates.

The result is a measurable and competitive stand.

Firms adopting digital twins capture more market shares which maintains higher uptime and operate more efficiently than competitors that are stuck in reactive mode.

The heart truth is that laggards will pay dearly for inefficiency. Digital twins don't just improve operations, rather, they will define what is possible with smart manufacturing. They make factories smarter and yield more profits. They give industrial engineers, CTOs and supply chain managers the tools to dominate the markets and not follow it.

Adoption isn't optional it is a is survival, growth and leadership mode.

Real World Applications: How Digital Twins Drives Results

Digital twins are not just theories, they are transforming operations today. Companies implementing them report measurable results that will go beyond guessing

For maintenance, a leading wind energy frame cut down on downtime by 35% after deploying a digital twin across 120 turbines. Every component was monitored in reality. Failures were also predicted and fixed before production was affected. Profit margins increased and maintenance budget reduced.

Production optimization is another area where digital twins shine. AI analyzes historical and live data to identify turbines that are underperforming. Adjustments are then applied automatically or flacked for immediate attention. Energy output will increase without additional hardware costs. Every turbine operates at its maximum potential.

Supply chain integration can also be overlooked sometimes but it is very important

Digital twins link windmill performance with spare parts logistics, teams in charge of maintenance and energy distribution

When the components needs to be replaced the system ensures parts are available, professionals are scheduled and the downtime is reduced.

Virtual testing is also an hidden advantage where engineers can stimulate stress weather patterns or change designs digitally before touching the original turbine

This will help to reduce risk, speed innovation and also improve ROI.

Digital Twins create measurable efficiency, maintenance that is productive and also operates with a high level of intelligence. Companies who adopt them gain higher reliability and lower cost living than competitors who rely on out dated methods and lagg behind.

Cutting-Edge Techniques – Wind Turbine Surveillance: From Aerial Imaging to 3D Fracture Detection Mapping

Drones: Your Aerial Inspection Partner.

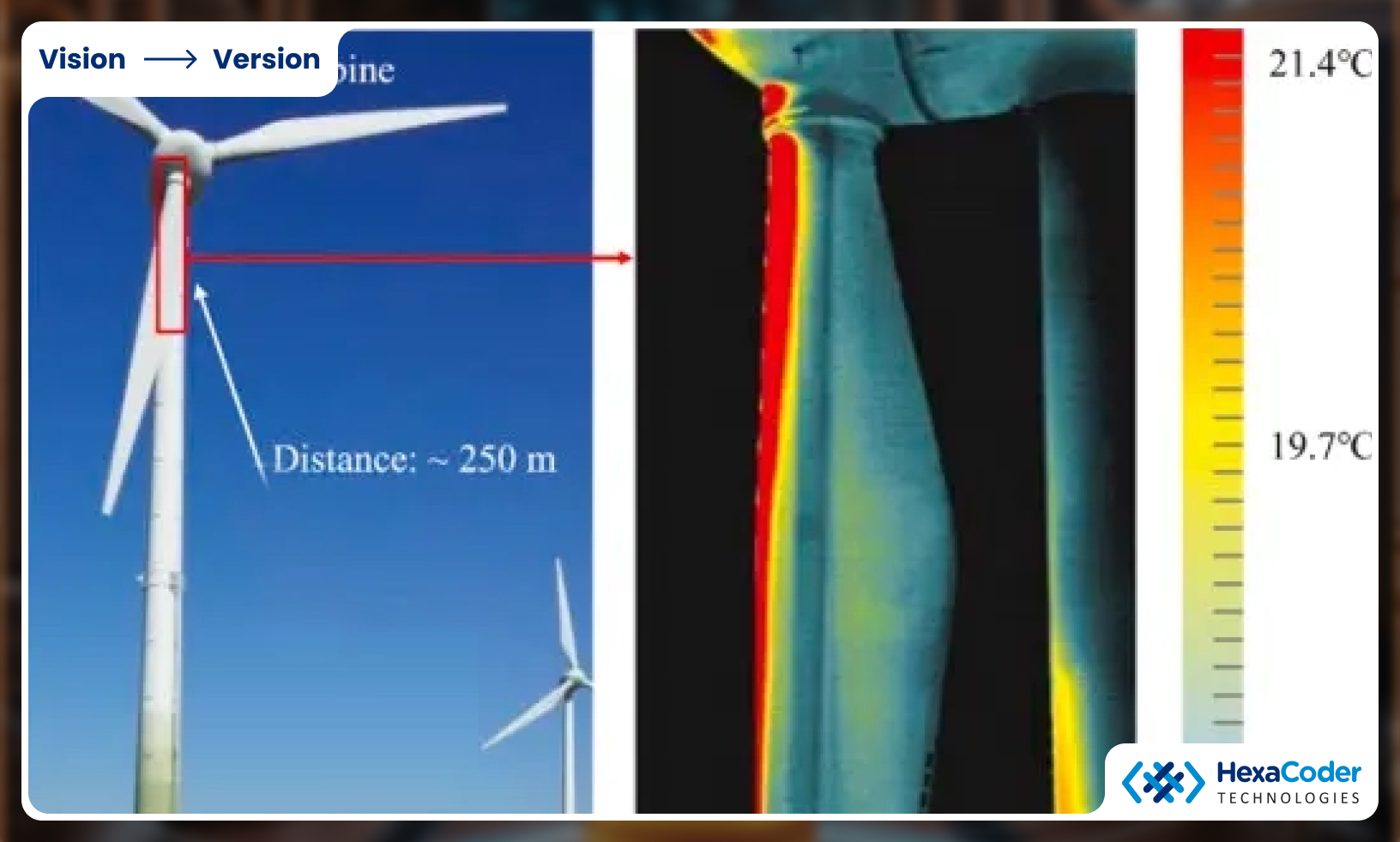

Scaling buildings and rope swinging have become obsolete. The remote-sensing technology mounted on modern drones is drastically improving efficiency for turbine inspections. Unlike traditional inspections which carry worker safety risks, modern construction drones such as the DJI Matrice 350 RTK with a flight time of 55 minutes and nimble control, ease the burden of operator safety by following well-planned flight paths, guaranteeing complete safety and placing crew members on the ground. Advanced tech drones are equipped with high-end cameras, thermal detectors, and a multitude of other sensors.

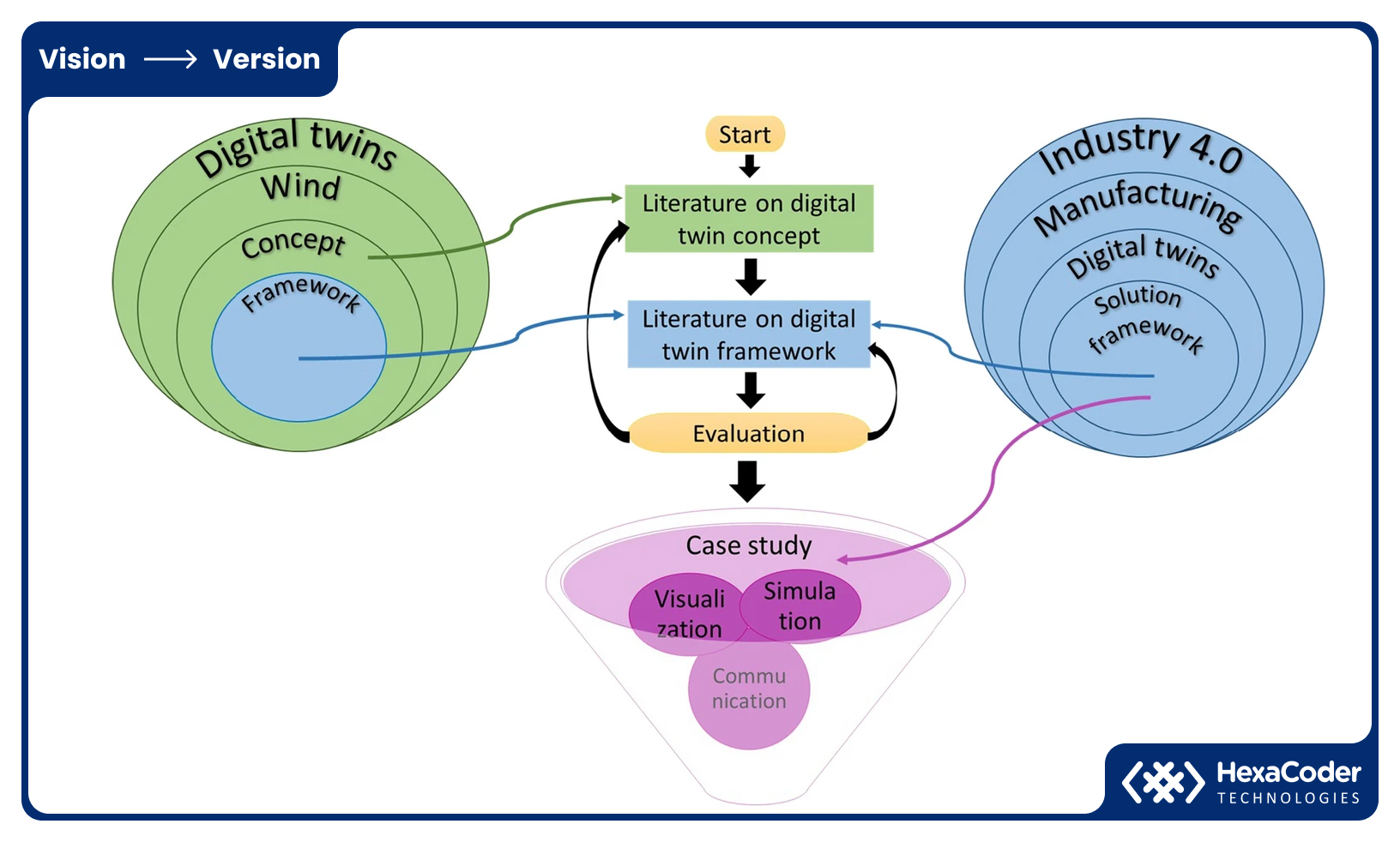

From Pixels to Digital Twins: 3D Reconstruction

Every aerial image captured serves as a base for a fully navigable 3D model. CAD designers and engineers leverage modern photogrammetry to process and analyze hundreds of overlapping 2D images, which when meticulously aligned, are transformed into dense clouds of high-precision 3D coordinates which are then rendered into a mesh. The resulting model is a Digital Twin, a virtual turbine model which simulates detailed visualization and exploration of any section of the model. The advantages of remote 3D inspection is that the risks and costs of traditional inspections are eliminated while providing insights that were previously impossible.

Smart Maintenance with AI driven Damage Mapping

Modern inspection is not just about seeing, it is more about understanding. Advanced algorithms and machine learning detects cracks, surface erosion, and other structural abnormalities automatically which classifies damage with pinpoint accuracy.

Each defect is shown directly on the 3D model which creates a visual and actionable dashboard of structural health. This data driven approach changes routine inspection into a maintenance strategy that is predictable, safeguarding turbine performance and extending operational life.

The result is fast, safe and smart wind energy maintenance that keeps the turbine spinning effectively while reducing cost, risk and lost time.

Future Outlook: Why Ignoring Digital Twins is Risky

The industrial landscape is now changing. Smart factories, predictive maintenance and connected supply changes are not just future concepts, they are the baseline to be the top in your niche.

Companies that delay digital twin adoption face three unavoidable risk which are:

- Blind spots on operation:

Without the involvement of digital twin adoption and real-time insights, machines will continue to fail unexpectedly which means downtime will become unpredictable and very expensive.

- Insufficient scaling:

Any wind farm or production line that is expanding without a digital twin is like flying blind. Scaling operations without intelligence leads to wasted resources, missed opportunities and slower response in market demand.

- Competitive lag:

your rival using digital twins capture market share faster, innovate faster and also reduces expenses faster. Just because you are falling behind does not mean you will lose just revenue you will also lose relevance.

The stakes are obvious. By 2030, industry 4.0 adoption with define who leads a renewable energy and manufacturing market

Digital twins are no longer the technical advantage, they are what makes you win strategically.

When you ignore this it means you are going to rely on processes that are outdated and you accept inefficiency which risks your market relevance. Call adopting them is exactly the opposite, data driven decisions and sustainable growth.

The future already operates on digital twins and only firms that act login performance profit and leadership.

Implementation Strategy: How to Turn Digital Twins into Profits.

Understanding digital twins is one thing while making them deliver measurable profit is another. Here is how top manufacturers balance this two:

- Map your assets:

Startt with a complete inventory of turbines, components and systems. Identify which assets will benefit the most from proper monitoring. Also prioritize high value and high risk machines.

- Integrate IOT Sensors:

Install sensors to capture the vibration, temperature, wind and energy output. Data is fuel and without it the twins cannot function properly.

- Deploy AI analytics:

Feed your sensor data into AI powered algorithms to predict machine failure and also optimize performance while highlighting inefficiencies. Make sure that the analysis aligns with your operational KPIs.

- Connect to the ecosystem:

Digital twins only reach their full potentials when paired together with supply chain, maintenance scheduling and energy management systems. A turbine failure triggers an automatic coordinated response: parts are ordered, teams are ddirected and production continues with no disturbance.

- Stimulate and innovate:

Use the twin for virtual testing of any upgrades design changes and operational adjustments that is made. Also implement improvement safely without risking revenue or downtime.

- Measure roi continuously:

Track your maintenance savings, up time improvement, energy output and operational efficiency. Every decision you make becomes a data driven investment.

- Skill systematically:

Start with a few serious turbines, change the process and then scale across the entire fleet. 100 of twins working together form a network intelligence system delivering irresistible gain.

- Use HexaCoder Technologies Digital Twin:

Make use of HexaCoder Technologies industry leading digital twin solution to implement, monitor and optimize your turbines and manufacturing processes. Their team make sure you maximize your ROI, reduce downtime and future proof operations.

Implementing digital twins is not just about technology it's more about strategy integration and measurable results. Those who follow this road map unlock both operational excellence and market advantage that computers cannot match with.

Conclusion: Will You Act Now or Fall Behind?

Digital twins are not optional they are very essential and the transform windmills from compassive machines into smart profit gaining assets. The turn downtown into predictability and turn guessing into insights, ordinary factories into smart manufacturing powerhouses.

The benefits are ready clear as the stop failures before they stop your profit, ensure every turbine performs at its peak efficiency allows ROI to be measurable and let your company lead the market .

The sticks are high industry 4.0 isn't coming it's already here and only firms that adopt digital twins get to operate matter and make innovation and operation faster. Those that hesitate risk inefficiency lost of more money and relevance.

The solution is very simple: implements digital twin strategically and connect them to your operations. Also leverage every insight they provide. Every rotation vibration and data points become an actionable intelligence.

Digital twin technology is your part to smarter, faster and more profitable operations.

Waiting isn't an option. The future of windmills and manufacturing is easier and runs on data intelligence and data twin.

To ensure your competitive edge and transform your operations into a Smart profit generating powerhouse, contact Hexacoder Technologies today and begin your digital twin journey.