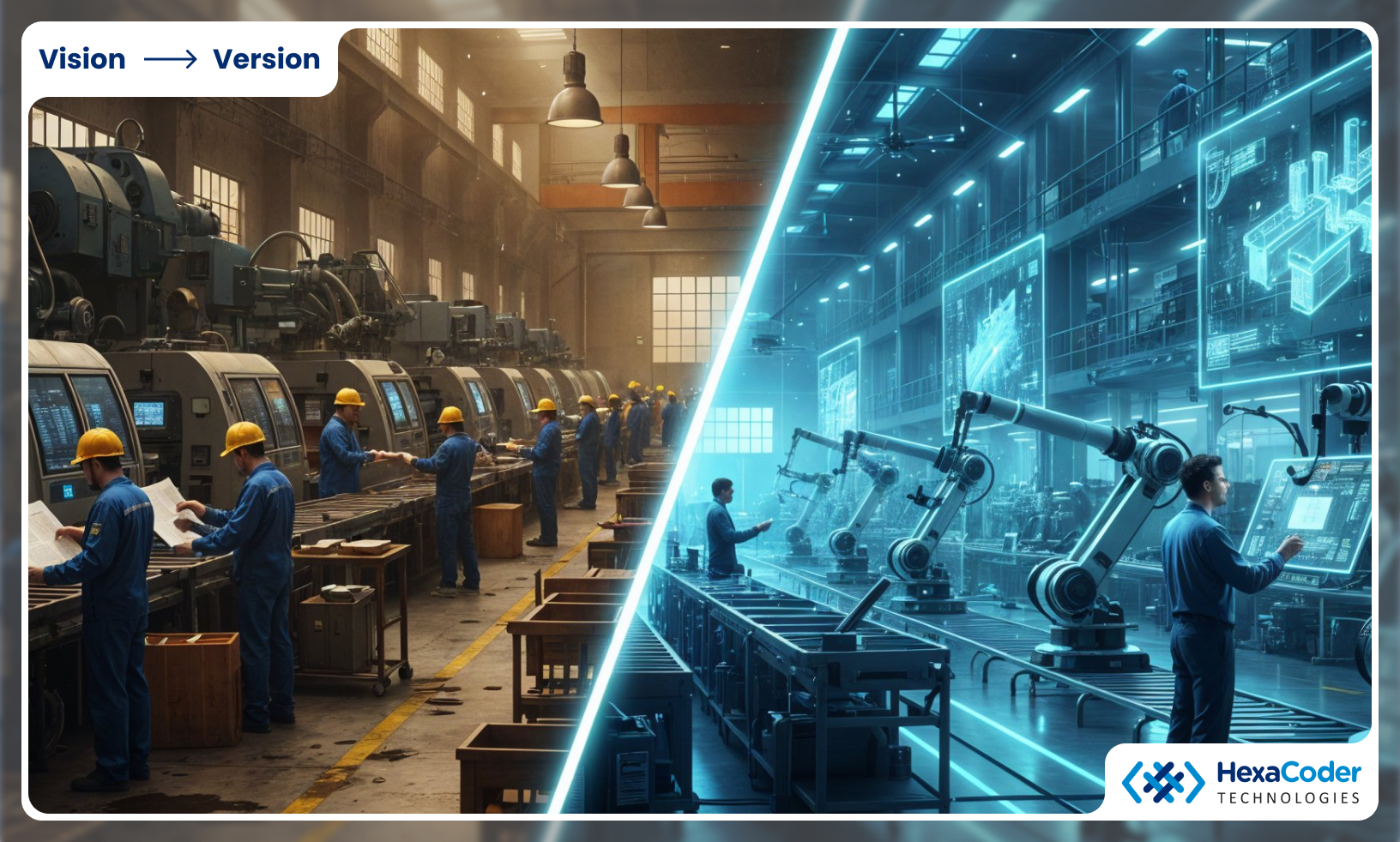

Factory floors are evolving faster than they have at any point in recent history. Production lines that once depended on human oversight now operate with precision, intelligence, and coordination that's nearly human-like. Machines talk to one another, processes adapt in real time to changes in supply, and managers can observe every aspect of their process from a single control point.

At the center of this revolution is Digital Twin Manufacturing, one that brings together physical assets and their digital twins in new forms that make manufacturing more predictable, more efficient, and more resilient. The technology is redefining what it takes to run a factory today.

Understanding Digital Twin Manufacturing

A digital twin in 3D is an internet replica of a facility, process, or asset in the physical world. It captures the actual system's behavior, performance, and structure. With sensor networks and data connections established on Industrial IoT, equipment and machine data streams into the virtual environment. Engineers, operators, and executives can now learn, test, and optimize their systems without interrupting production.

Think of it as an active expression that captures the way something is carried out in its entire lifespan. In Digital Twin Manufacturing, this expression provides insight that was before unimaginable. Every component of a machine, every robotic arm movement, and every conveyor motion can be viewed and optimized in the virtual environment before carrying out in the real-world environment.

The concept is founded on four key pillars:

- Physical asset – The equipment or plant to be represented.

- Digital model – The computerized 3D environment showing structure and function.

- Data connection – Data flows of operational data collected with Industrial IoT sensors.

- Feedback loop – Continuous learning and optimization between the digital and physical domains.

When all these work together, production moves from reactive control to proactive management. Instead of waiting and hoping that a machine will break, operators will have advance notice when and why. Instead of guessing how to improve a process, they experiment with it virtually in advance. That is the character of a Smart Factory.

The Rise of the Smart Factory

Smart Factory is a new age in industrial progress. It interlaces connectivity, automation, and analytics to create places that adapt to conditions and learn from experience over time. This is not a revolution about replacing human beings but one that outfits human beings with tools to help them expand their perception and vision.

In a smart environment, production data is no longer trapped in isolated systems. It is shared among design, manufacturing, logistics, and maintenance operations freely. Decision-makers can see performance in real time and adjust throughout the organization in real time.

Study by industry analysts shows that manufacturing plants adopting digital twin models have measurable results. Some of them have up to thirty percent less downtime, twenty percent gain in throughput, and reduced energy consumption in factories. These results show that intelligence, not scale, defines manufacturing's future.

A Smart Factory based on digital twins and Industrial IoT is an awareness system. It perceives, understands, and responds. It is aware of what is occurring at every production level and responds upon that information with precision.

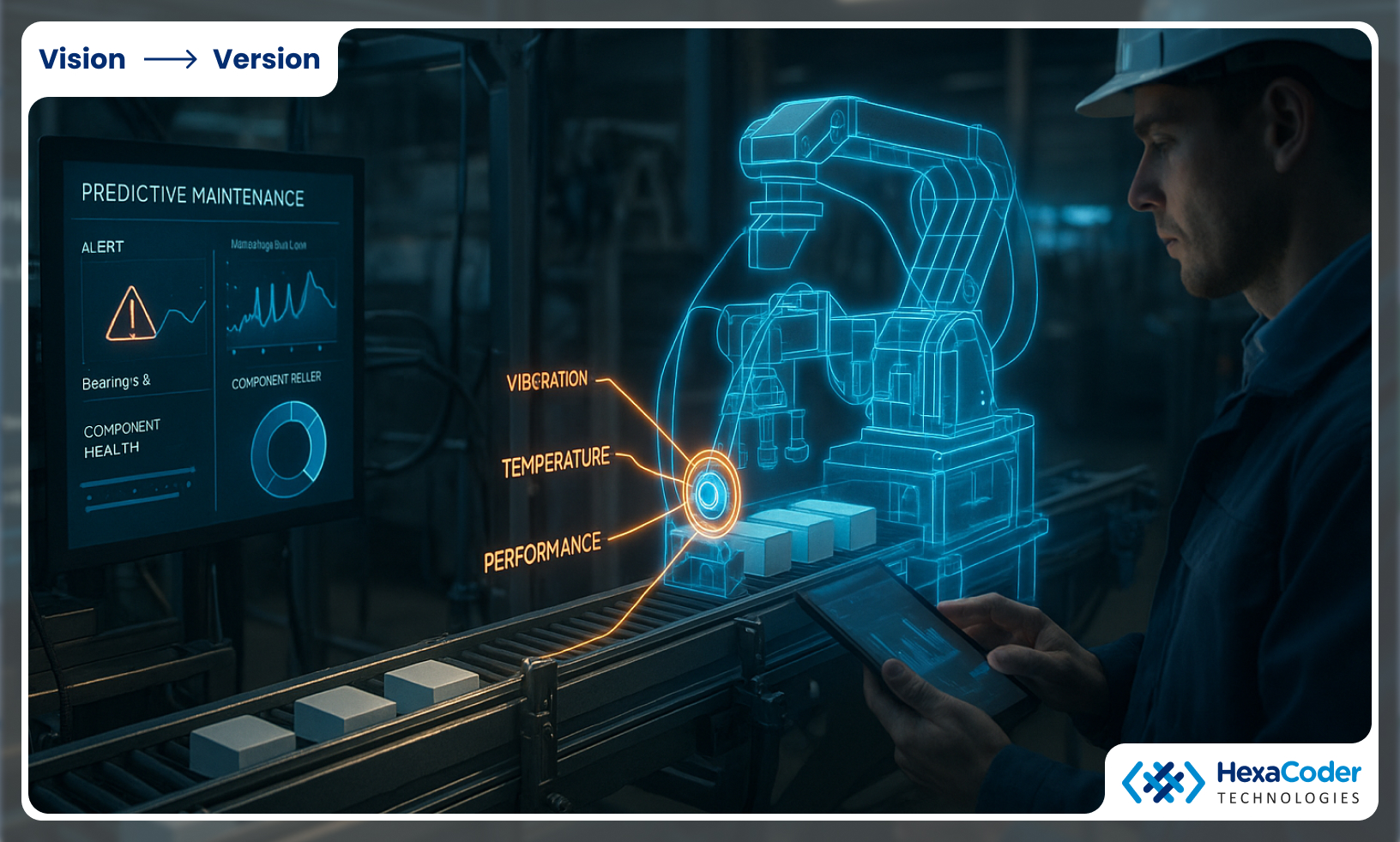

How Manufacturers Use Digital Twins for Predictive Maintenance

Maintenence has been one of manufacturing's most costly and unpredictable problems for years. Breakdowns in equipment cause production delays, increase cost, and result in waste. Traditional maintenance methods rely on fixed schedules or crisis response, both of which are inefficient.

Digital Twin Manufacturing introduces a new benchmark with predictive maintenance. With Industrial IoT connecting assets and sensors, manufacturers are able to identify the pre-breakdown indications of stress, wear, or imbalance well ahead. The digital twin processes this information and identifies which part needs to be rectified.

Let's have an example. A packaging facility sees vibration increase on one of its high-speed labelers. The digital twin analyzes the trend and checks it against history's performance data. The system determines that a bearing is near the end of life. Maintenance is performed with no interruption during scheduled downtime.

This is how manufacturers use Digital Twins for predictive maintenance. It is an easy four-step process:

- Sensors capture operating data such as vibration, temperature, and pressure.

- The digital twin interprets the data in terms of system behavior.

- Analytics identify potential defects and estimate when failure is about to occur.

- Maintenance is carried out precisely when required, not prior to or after.

The benefits are experienced across the organization:

- Unplanned downtime is minimized.

- Maintenance budgets are predictable.

- Equipment life cycles are extended.

- Safety is increased through controlled interventions.

Predictive maintenance through Digital Twins turns manufacturing into a forward-looking domain rather than a response-based one.

Applications Beyond Maintenance in Manufacturing

Maintenance is one major use case, but digital twins influence nearly every area of the manufacturing process.

-

Product Development and Design

Engineers can design new products within the virtual world. They can test stress points, assembly processes, and materials behavior prior to constructing a single prototype. This accelerates development cycles and minimizes waste.

-

Production Planning and Optimization

Plant managers can simulate processes, test demand fluctuations, and trial line configurations. Changes that previously needed physical testing can now be simulated digitally, saving time and money.

-

Worker Training and Safety

Operators can utilize digital twins to train in an immersive manner. They learn in a virtual environment how to manage unusual conditions in a safe manner before applying that experience to the shop floor. This boosts confidence and safety levels.

-

Supply Chain and Logistics

A connected digital model allows companies to see inventory streams and identify delays or inefficiencies in dispatch. This transparency allows for better forecasting and coordination with suppliers.

-

Sustainability and Resource Efficiency

Digital twins help monitor material usage, emissions, and energy use. Through scenarios for different production approaches, manufacturers can determine the most sustainable course of action while not sacrificing quality or delivery.

Every component of the manufacturing ecosystem benefits from these insights. Seeing and optimizing before progressing allows for a new age of accuracy and responsibility.

The Role of Industrial IoT

In essence, Industrial IoT integrates physical machines with their digital counterparts. Without connectivity, however, digital twins are mere static snapshots. With connectivity, digital twins provide an uninterrupted flow of information.

Machines have sensors that capture and report their operating temperature, movement, and other key performance indicators. This information is collected by gateways and controllers and relayed to several states of analysis. The digital twin then analyzes and processes this information and relays the current state of each asset.

The factory communicates with and amongst itself. Real-time adaptive production adjusts to external and internal condition changes, machines autonomously notify the system when recalibrating is required, and systems self-synchronize. The simplicity of integrated dashboards is the key to wireless management of complex operations, allowing massive control over unprecedented interconnectivity.

The connectivity captures and transmits data; the digital twin analyzes and processes it; and the smart factory implements it. Each of the three components reinforces the others, establishing an interdependent cycle of continuous operational enhancement.

Measurable Benefits for Manufacturing Executives

For top executives, technology adoption must be reflected in financial and operational performance. The payoffs of digital twin implementation are tangible and strategic.

-

Faster Decision-Making

Graphic models supported with accurate data enable the leadership groups to react faster. They do not have to wait for reports or audits; they can see and understand operations instantly.

Improved Resource Utilization

The manufacturers can track where the resources are being utilized most efficiently and relocate capitals to where the return will be highest.

-

Operational Cost Savings

Predictive maintenance, energy efficiency maximized, and reduced rework all lead to a vast reduction in operational expenses.

-

Improved Product Quality

Feedback loops between production and design allow issues to be remedied as they arise. The ultimate outcome is more consistent quality in product lines.

-

Environmental and Regulatory Compliance

Environmental objectives are supported by digital twins by whereenergy or material waste occurs. This helps meet corporate and regulatory sustainability targets.

These benefits underpin the strategic significance of Digital Twin Manufacturing. It is not a standalone solution but a viable platform for continuous efficiency and evolution.

The Path Towards Self-Optimizing Factories

With technology evolving, digital twins are becoming more self-sufficient. Through the use of artificial intelligence and machine learning, it is creating systems that not only read data but also recommend or implement improvement independently.

The factories of the near future will be capable of self-optimization. A production facility will adapt its settings to react to changes in demand. A community of plants will share performance metrics so that every building benefits from others' experience. Maintenance schedules will synchronize with predicted performance results.

This level of autonomy will reframe competitiveness. The application of digital twins, advanced analytics, and networked systems will drive manufacturing to be faster, cleaner, and more adaptable to change.

Manufacturers have the potential to prepare their infrastructure and their people for the transition. To invest in digital twin capability today lays the groundwork for tomorrow's smart enterprises.

Constructing the Right Foundation

Transitioning to Digital Twin environments is not about buying new hardware but about bridging the existing systems.

The best implementations begin with mapping high-impact areas say, a bottleneck process or major asset. From there, a pilot twin is established and matched with control systems already in place. Once benefits are measured and validated, the approach can be implemented companywide.

Robust data governance, secure networks, and well-understood communication between operations and technology teams are required. Training employees to comprehend insights from digital twins is required. A digital twin will only generate value if people know how to react to what it is communicating.

Producers that transform incrementally through the transformation experience faster adoption and improved returns. It is evolution, not disruption.

Factories were once operated on experience and intuition. Nowadays they are operated on insight and precision. Digital Twin Manufacturing, with Smart Factory approach and Industrial IoT connectivity, allows organizations to view every aspect of their operation with clarity and control.

The result is learning manufacturing that adapts and improves continuously.

Here at Hexacoder Technologies, we help manufacturers design and implement digital twin systems that reveal performance, reduce risk, and accelerate transformation more quickly. From IoT integration and modeling to predictive analytics, our solutions make factories more intelligent, productive, and sustainable.

The future belongs to those who can look beyond what's happening today and imagine what's coming tomorrow. That begins with a digital twin.

Frequently Asked Questions

What is Digital Twin Manufacturing?

Digital Twin Manufacturing is the process of creating a sophisticated digital copy of an already existing product, machine, or manufacturing process. The digital model mimics the operation and behavior of the actual system. It allows manufacturers to simulate concepts, monitor performance, and maximize processes without stopping actual production. The result is increased efficiency, minimized errors, and enhanced quality output.

How is a Digital Twin related to Industrial IoT?

Industrial IoT provides the data that brings a digital twin to life. Sensors across the factory floor measure vibration, temperature, speed, and power usage. This continuous stream of data finds its echo in the digital twin, and it helps engineers track conditions, detect inefficiencies, and run the operations more optimally. The more networked the plant is, the more accurate and insightful the twin is.

In what ways do businesses utilize Digital Twins for predictive maintenance?

Businesses utilize Digital Twins to monitor the condition of machines and prevent unexpected failures. The twin observes data from operating equipment and identifies early signs of wear, overheat, or imbalance. With this data, maintenance teams can act before a breakdown occurs. This reduces downtime, extends the life of expensive assets, and ensures seamless operation.

What are the most important benefits of applying Digital Twins to manufacturing?

Manufacturing plants become more productive and responsive through the use of Digital Twins. Engineers can pretest things and adjust them without having to waste resources and time. Production teams can utilize resources more effectively and respond faster to changes in demand. Executives see factory performance better and are able to plan more effectively. Overall, it provides a stronger basis for quality, productivity, and long-term growth.

What are the hurdles for businesses in implementing Digital Twins?

The major issues are high initial expenses, integrating legacy systems with new technology, and staff training to make best use of the tools. Most manufacturing plants contain aging equipment that is not yet ready to be networked by computerized systems. To succeed, companies need a solid roadmap, effective departmental collaboration, and consistent data management practices. With all those pieces in place, the return on investment becomes evident.

What is the future of Digital Twin Manufacturing?

The future of Digital Twin manufacturing will be more people, machine, and data integration. Production systems will be more self-optimizing and adaptive, reacting to changes in demand, supply, and machine performance without human action. Manufacturers embracing digital twins today will be better prepared for a future in which every choice is based on precise, real-world insight.