Virtual Twin Experiences for Manufacturing Industries

The quarterly review was not going well. Across the polished table, the numbers told a harsh story: production delays, unplanned downtime, and energy costs climbing higher each month. The factory floor was running at full tilt, yet profits were shrinking. The chief executive leaned back, not because she did not see the issue, but because she saw it too clearly.

The plant, the machines, the spreadsheets all showed what had already happened. What she needed was something different. Not another stack of reports. Not another round of postmortem meetings. She needed a way to look ahead. A tool to see how choices would play out before committing millions to new lines of equipment or redesigning supply routes.

This is where Virtual Twin experiences enter the conversation.

They offer a living picture of operations, one that allows leaders to test ideas, explore options, and make tough calls with confidence, knowing the likely results before they happen.

For today’s manufacturing leaders, the question is no longer whether Virtual Twins will matter. The real question is: How soon will you put them to work in your company?

Beyond the Hype Why Virtual Twin Is the Next Leap

Manufacturing executives are used to new buzzwords every year. They flash brightly and then vanish before they prove their worth. Virtual Twin is different. It is not simply another passing fad. It is a realistic way of knowing and understanding industrial processes.

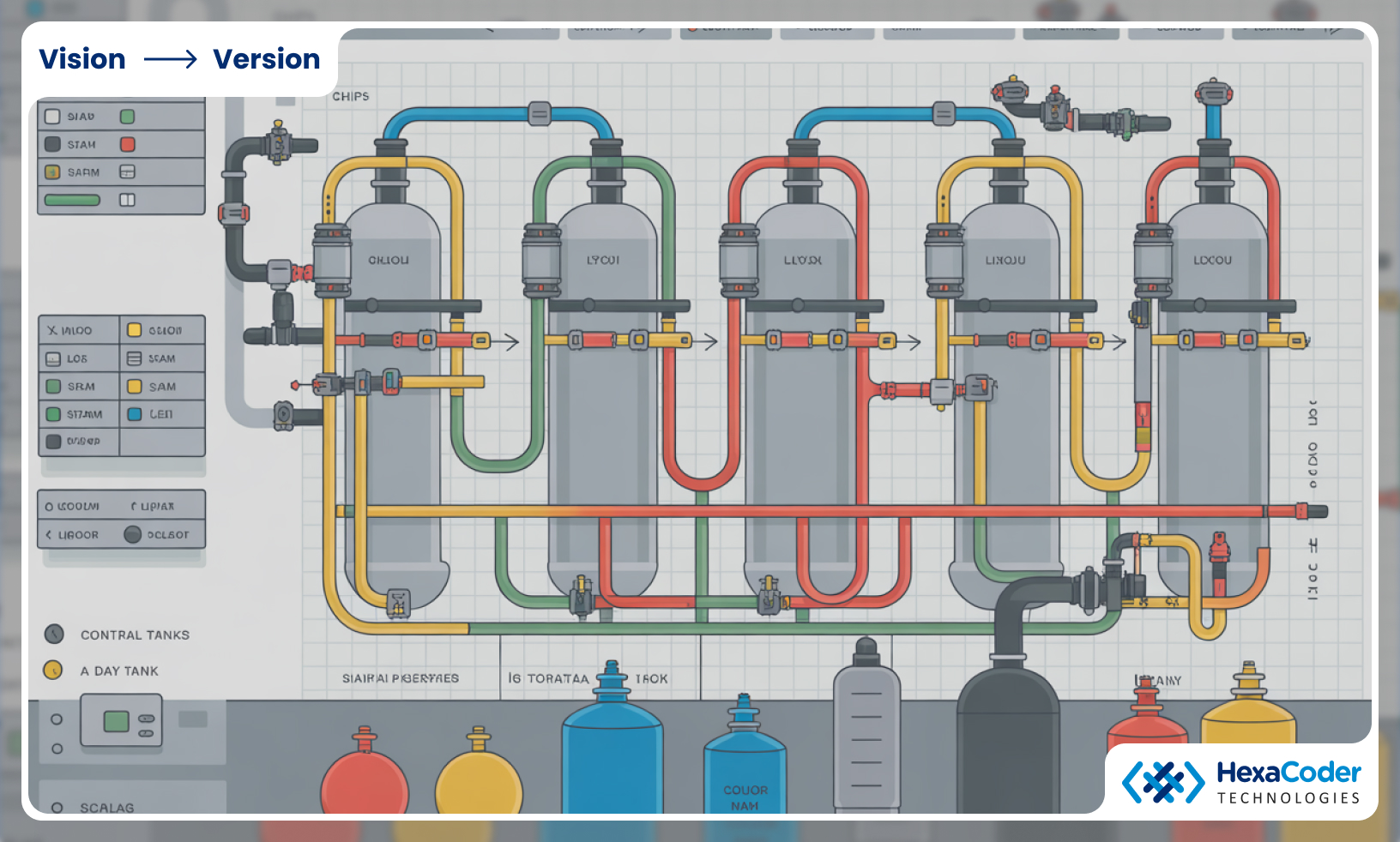

A Virtual Twin is an actual replica of a process, a factory, or an entire supply chain. Historical records merely represent what's happened. A Virtual Twin shows what's happening in the moment and gives leaders a tool to look ahead. It is not generating more reports. It is simplifying complex operations and making them meaningful to decision makers.

Production now leaves little room for mistake. Competition is international and intense. Customers demand quicker turnaround, more variation, and more commitments to the environment. Responding after problems occur is no longer good enough. Leaders need skills that allow them to anticipate problems before they reach the bottom line.

That is what sets the Virtual Twin ahead. It shifts planning away from reaction and into anticipation. It enables executives to walk through different scenarios, compare outcomes, and test strategies before rolling them out on the plant floor. That change is not a trivial tweak. It is a change in decision-making and planning for the future.

The Executive Pressures Behind Adoption

Production change does start with pressure. CEOs don't select new methods because they are hip. They choose them because the current way of doing business no longer cuts it. The shift towards Virtual Twin goes on this basis. It's a response to real and continuing challenges on the factory floor and in the boardroom.

Precarious supply chains pose one of the most powerful pressures. A downturn in one segment can halt, or hinder, production in another. Shortages of materials, congestion in shipping, and sudden fluctuations in price are no longer the norm. Managers need a simpler way to develop contingency plans in advance before problems occur.

But another stress is rising expenses. Energy costs, equipment upkeep, and labor charges are all going up. Planning mistakes are more expensive than ever. Managers can no longer afford to try things out. They need a reliable way to make the best decision while maintaining production in motion.

Sustainability, too, is a growing demand. Governments are passing stricter legislation, and consumers are watching how factories dispose of waste and use energy. Meeting these demands without cutting back on production has been a delicate balancing act.

And then there is the matter of decision making itself. Companies gather huge volumes of data, but a lot of it arrives too late to influence the day-to-day decisions that shape performance. Managers have to fall back on guessing when they need clarity.

Virtual Twin is responding to these pressures. It offers managers an experiential method of looking ahead, of testing out different possibilities in a risk-free environment, and of progressing with confidence in fast-changing conditions. This is why many executives today regard it as a fundamental tool for manufacturing today.

How Virtual Twins Are Used in Manufacturing

Executives will usually ask only one question: what does a Virtual Twin really do in a factory. The response is found in obvious, useful applications that facilitate everyday work and long term planning.

A major application is in product design. Managers no longer have to wait for a physical model. They can view new ideas in a working model of the production process. Mistakes are found earlier, and redesigns are less expensive. This reduces the idea-to-launch timeframe.

Another use is in plant design. Managers can test out substitute floor plans in a Virtual Twin prior to relocating large machinery or buying new equipment. They can examine material flow, how staff work, and where there might be bottlenecks. This eliminates waste and avoids expensive errors during the expansion process.

Maintenance is also enhanced. One of the most costly problems in production is equipment breakdown. Managers can track wear before production stops with a Virtual Twin. Repairs and part replacements are done on time, minimizing downtime and extending machine life.

Employee training is another use that proves useful. Instead of learning by hand or following veteran staff, new staff can learn by doing in a simulated facsimile of the factory. This builds competency and reduces mistakes once they arrive at working on actual machinery.

These applications demonstrate that Virtual Twins are concrete realities. They are already helping factories save resources, improve safety, and plan with greater confidence.

Virtual Twin vs. Digital Twin

Many leaders hear both terms and wonder if they are referring to the same thing. The difference matters because it changes how each one is used.

Digital Twin

- Works like a rich history of a machine or process.

- Shows current performance and past activity.

- Great for monitoring, but not when planning future moves.

Virtual Twin

- Acts as an operating replica of an operation.

- Lets test out options and analyze likely outcomes with managers prior to changing the plant.

- Facilitates decision making by showing what different options could lead to.

Why the difference matters

A Digital Twin helps you see what is happening now while a Virtual Twin helps you prepare for what can happen next.

Both are valuable, but only the Virtual Twin helps leaders simulate decisions before spending money and resources.

Simplifying, the Digital Twin tells you what is, and the Virtual Twin shows you what can be.

Critic Applications That Matter to Executives

Leaders utilize Virtual Twins to highlight directly affecting costs, safety, and operations. The following are main applications they identify in manufacturing:

Optimizing production

- Test workflow changes before applying them on the factory floor.

- Spot where errors or delays can happen and avoid them.

- Keep production levels steady with wasted effort or time kept to a minimum.

Lowering equipment problems

- Catch issues before they lead to work halt.

- Schedule maintenance in the optimal time to prevent surprise shutdowns.

- Increase the lifespan of machines and lower repair costs.

Foster environmentally friendly behaviors

- Find ways to use less energy and produce less waste.

- Meet regulations and customer demand without cutting output.

Training employees safely

- Let employees get experience on tasks in a safe simulation of the plant.

- Fewer errors and accidents when working actual equipment.

- Gain skill and confidence more rapidly than learning through observation alone.

Decisions on changes

- Experiment with different ideas before buying new machines or moving equipment around.

- Compare results of different methods to see which works best.

- Make decisions more uncertain and transparent.

These arguments prove that Virtual Twins are usable tools employed by leaders to save money, promote safety, and optimize operations on a day-to-day manufacturing scale.

The Value for Executives

Executives need to appreciate that new ways are an investment well worth making. Virtual Twins deliver benefits executives can readily measure:

Lower operating costs

- Save lost materials, energy, and labor time.

- Prevent mistakes before they occur on the factory floor.

Less disruption

- Catch problems early so equipment breakdowns occur less often.

- Schedule repairs and replacements in a way that keeps production going.

Faster decision-making

- Look at options ahead of time before parting with money or resources.

- Make decisions based on sound understanding and not hypotheses.

Better performance by employees

- Employees learn faster and make fewer errors.

- Safety improves as the practice is carried out within a secure environment.

Better preparation for change

- Try out layouts, equipment, or processes before making changes final.

- Ensure the factory can produce based on customer requirements and regulations efficiently.

Expenditure on Virtual Twin experiences is not technology for technology's sake. It's saving costs, reducing risk, and creating more resilient day-to-day operations and long-term growth.

The Human Factor in Adoption

New tools don’t automatically lead to improved output – it is people who make the difference. Virtual Twins achieve their full potential only when the employees and managers understand what their roles are and how to make them work.

Staff involvement early on

Engage employees right from the start. Solicit their input on modifications to ensure that the adjustments align with the everyday reality of their work.

Hands-on training

Workers should have the opportunity to practice in a training scenario before they have to use the real machines. Training should be part of the daily work instead of an extra activity.

Clear communication

Harsh language is not needed to explain why something is beneficial and what are the objectives. Show how it helps the employee do their own job better and not just management’s.

Leadership involvement

Executive leaders should take the lead to use and set expectations. Visible support from the top helps the rest of the organization to adopt new practices.

Encouraging good habits

Reward effective planning, concentration, and safe work with incentives. Positive reinforcement should be used to strengthen habits that high performance and error avoidance are associated with.

When the employees understand why something has to be done and how it benefits them, it is easier to adopt. Virtual Twins provide the best value when users employ them with confidence and in a consistent manner.

A Working Roadmap for Executives

In order to implement Virtual Twins successfully, there needs to be preparation, people, and equipment. Executives do not have any complicated steps to take:

Analyse and Evaluate Procedure

- Look at and evaluate the steps in a procedure.

- Determine which steps have the highest frequency errors, postponements, or unnecessary spends.

- Discover which steps may need fine-tuning.

- Define the end result.

- Determine which adjustments should be made, like reducing halts or speedy shipment of goods.

- Ensure the end result is simple and quantifiable.

Engage Employees Early

- Engage employees up front.

- Obtain ideas and enthusiasm, and invite people to help in co-creating change.

- Show how the proposed change will enhance and streamline work.

Provide Procedure Instruction and Safe Simulations

- Offer procedure instruction.

- Let people simulate actions in a risk-free space before interacting with actual tools.

- Involve the higher ups and the people who will operate the equipment in repetitive sessions for consolidation.

Focus on Pilot Areas

- Focus on a single location.

- Tackle one section of the plant to evaluate the intended effects of the modifications.

- Use these observations to enhance other sections over time.

Measure the effects.

- Measure enhancements in output, safety, and cost: these will indicate the actions to take regarding the plant.

- Motivate sequential movement.

- Praise planning, attention to detail, and safe actions.

- Develop routines to enhance predictability and automation within a process.

By embracing such steps, executives can deploy Virtual Twins in a practical manner, support routine operations, and gain support from the employees.

Insights for Business Leaders

Virtual Twins do more than improve factory operations. They are a tool for decision-makers for more effective cost management and operational improvement. They work best when staff understand the value of the Virtual Twins and the procedures to use them safely.

Managers should prioritize areas with the greatest problems of errors, bottlenecks, and excessive costs. Employees should be encouraged to set change goals to promote ownership. Staff-led change goals not only set Quick Wins, but also encourage ownership. Taking small incremental steps and focusing on the details are effective ways to manage change and minimize exposure.

Improved operational confidence, minimizing unnecessary factory downtime, and optimizing energy use and materials allocation are clear advantages of Virtual Twins. Enhanced operational confidence results in a better, more productive, and safer work environment.

The End

Practical results based on intended use stem from investing in Virtual Twins. By focusing on people, processes, and aligned goals, you can create a factory capable of more dependable operations and operational readiness for the unpredictable tomorrow.

Virtual Twins provide tangible ways to enhance operations, reduce expenses, and improve performance for leaders in manufacturing. Their benefits are maximized with comprehensive staff training, careful planning, and clear objectives.

Success comes from focusing on what works in practice rather than adopting methods for appearances. By looking closely at areas where mistakes and delays happen, involving employees from the start, and taking deliberate steps, leaders can achieve improvements that are measurable and meaningful.

The results are concrete. Factories run more reliably, employees perform tasks with confidence, and resources are used more effectively. These gains improve daily operations and prepare the organization to handle challenges in the future with steadiness and assurance.

In the end, Virtual Twins help leaders make sound decisions, support their teams, and maintain workplaces that operate safely, smoothly, and efficiently.