Why Bus Manufacturers Are Using 3D Configurators

The global bus manufacturing industry is undergoing a structural shift. Urbanization, electrification, regulatory pressure, and demand for customized public transport solutions are reshaping how buses are designed, sold, and produced. In this environment, traditional sales catalogs, static drawings, and manual configuration processes are no longer sufficient.

Bus manufacturers are increasingly adopting 3D configurators to manage complexity, reduce errors, and align customer expectations with production realities. What started as a visualization tool has evolved into a strategic system that connects sales, engineering, and manufacturing into a single digital workflow.

This shift is not about aesthetics. It is about operational control, scalability, and competitiveness in a market where customization is no longer optional.

Understanding 3D Configurators in Bus Manufacturing

A 3D bus configurator is a digital system that enables manufacturers, dealers, and customers to build, visualize, and validate bus configurations in real time within predefined engineering and regulatory boundaries. Unlike traditional brochures or static CAD renders, configurators allow stakeholders to interact with the product dynamically—selecting layouts, powertrains, seating configurations, accessibility features, safety systems, interiors, and branding elements while instantly seeing the impact of each choice.

What differentiates a true 3D configurator from basic visualization tools is its rules-based intelligence. Every option is governed by logic tied to manufacturing feasibility, component compatibility, weight limits, homologation rules, and regional compliance standards. Invalid combinations are automatically restricted, ensuring that what is configured can actually be produced. This eliminates ambiguity between what is shown, what is sold, and what is manufactured.

From an operational perspective, the output of a 3D configurator is not merely a visual model. It generates structured configuration data that can feed directly into ERP, PLM, CPQ, and manufacturing execution systems. Bills of materials, option codes, and production parameters are aligned from the earliest stages of customer interaction.

For bus manufacturers, this capability closes a long-standing gap between customer intent and factory execution. Instead of relying on manual interpretation, drawings, or repeated clarifications, all stakeholders work from a single, validated digital source. This improves accuracy, shortens lead times, and creates a foundation for scalable, digitally driven manufacturing operations.

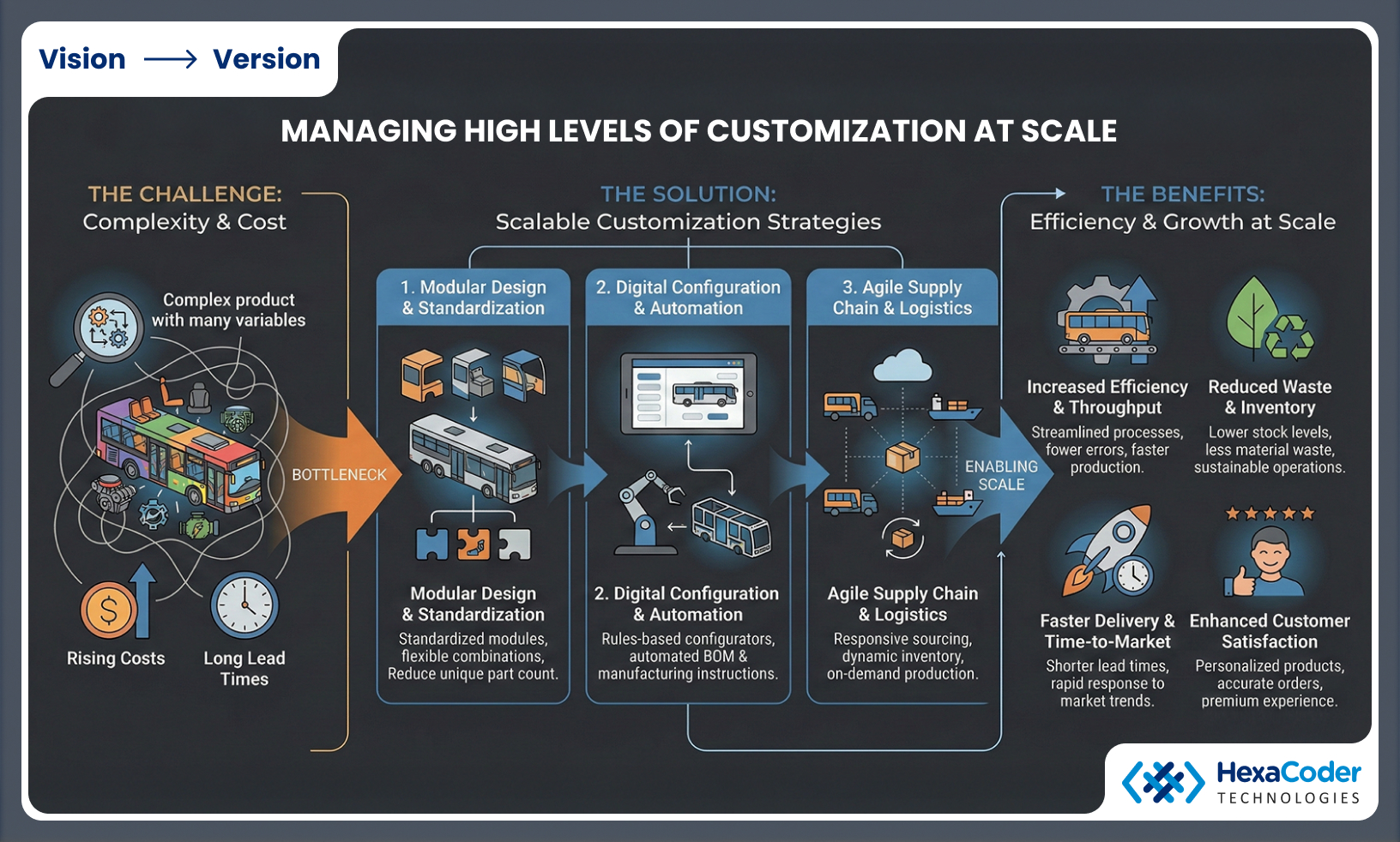

Managing High Levels of Customization at Scale

Bus manufacturing is fundamentally different from mass-produced passenger vehicles. Every order often carries unique requirements based on route conditions, passenger volumes, accessibility mandates, climate, energy infrastructure, and operator preferences. City buses, intercity coaches, electric buses, school buses, and airport shuttles each introduce distinct configuration complexity.

Managing this level of variability manually or through disconnected tools introduces significant risk. Incompatible selections, missed compliance requirements, and inconsistent specifications lead to production delays, rework, and cost overruns. As customization demand increases, these risks multiply.

3D configurators bring structure and control to this complexity. Manufacturers can define modular product architectures—standardized components such as drivetrains, seating systems, HVAC units, battery packs, doors, and interiors—while still offering extensive customization within safe limits. The configurator guides users through valid configuration pathways, ensuring flexibility without compromising manufacturability.

This approach enables mass customization without operational chaos. Instead of expanding inventory or increasing engineering workload, manufacturers manage complexity digitally. Custom options are assembled logically rather than manually interpreted, keeping production predictable and scalable.

As product portfolios expand and electric and smart bus variants become more common, this capability becomes critical. 3D configurators allow manufacturers to scale offerings across markets and use cases while maintaining control over cost, quality, and production efficiency—turning customization from a liability into a competitive advantage.

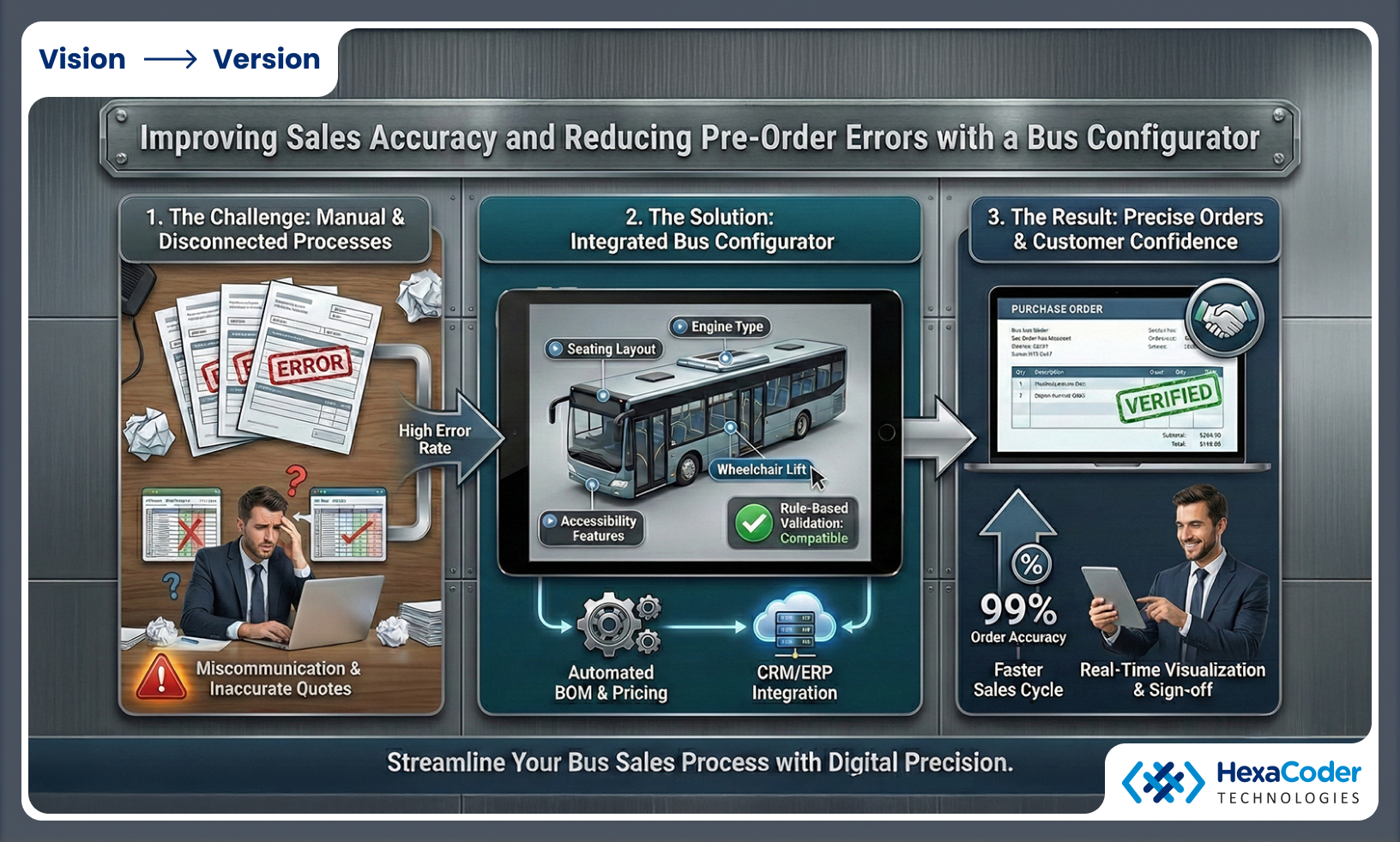

Improving Sales Accuracy and Reducing Pre-Order Errors

One of the most persistent challenges in bus manufacturing lies in the gap between sales commitments and production reality. Sales teams often work under pressure to meet tender requirements or operator expectations, relying on spreadsheets, drawings, and experience-based assumptions. Errors introduced at this stage frequently surface late—during engineering validation or production—when correction is expensive.

3D configurators eliminate this problem at its origin. Sales teams, dealers, and customers interact with a shared, validated configuration environment. Every selection is automatically checked against engineering rules, regulatory constraints, and component compatibility. Infeasible combinations are blocked instantly, preventing incorrect specifications from entering the system.

This dramatically reduces reliance on manual documentation and repeated clarification cycles between sales and engineering. Configurations are clear, complete, and production-ready from the outset. Tender submissions become more accurate, and order confirmations carry significantly lower risk.

For manufacturers, the impact is measurable. Engineering change requests decrease, production disruptions are reduced, and delivery schedules become more reliable. Internal teams spend less time correcting errors and more time improving products and processes.

Over time, improved sales accuracy strengthens trust with customers and public transport authorities. Manufacturers build a reputation for reliability and transparency—delivering exactly what was promised, without last-minute surprises or costly rework.

Enhancing Customer and Operator Engagement

Bus purchases represent high-value, long-term investments for operators, municipalities, and transport authorities. Decisions involve multiple stakeholders—technical experts, procurement teams, planners, and regulators—each with different priorities. Communicating complex configurations through static documents is inefficient and often leads to misunderstandings.

3D configurators fundamentally change this interaction. Stakeholders can see and explore the exact bus configuration in real time. Interior layouts, accessibility features, safety systems, and branding elements are visualized clearly, enabling informed discussions and faster consensus.

This transparency builds confidence. Operators understand precisely what they are approving, and manufacturers reduce the risk of misaligned expectations. Trade-offs—such as seating capacity versus accessibility, or battery size versus range—can be evaluated collaboratively rather than debated abstractly.

In public tenders, configurators help manufacturers demonstrate compliance clearly and consistently. Instead of lengthy technical explanations, solutions are shown visually and validated logically. This reduces interpretation risk and accelerates approval cycles.

For private operators, configurators turn the sales process into a collaborative design experience. Engagement improves, trust strengthens, and decision timelines shorten. Ultimately, this leads to stronger relationships, higher satisfaction, and better long-term partnerships between bus manufacturers and their customers.

Streamlining Engineering and Production Planning

Beyond sales enablement, 3D configurators play a central role in improving engineering efficiency and production planning accuracy. Once a bus configuration is finalized, the configurator can automatically generate structured outputs such as bills of materials (BOMs), option codes, routing logic, and build parameters. This eliminates the need for manual translation of customer requirements into engineering documentation.

When integrated with ERP, PLM, and MES systems, configuration data flows directly into procurement, scheduling, and shop-floor execution. Component availability, production capacity, and lead times can be aligned early, reducing surprises later in the manufacturing cycle. Manual data re-entry is minimized, lowering the risk of transcription errors and version mismatches.

Engineering teams benefit significantly from this automation. Instead of repeatedly validating similar configurations or correcting sales-stage errors, engineers can focus on design optimization, platform improvements, and innovation initiatives. Configuration logic is embedded once and reused consistently across orders.

For production teams, the clarity is immediate. Work instructions are unambiguous, component kits are accurate, and assembly sequences align with factory constraints. Over time, this consistency improves throughput, reduces changeovers, and shortens lead times.

As production volumes increase or variant complexity grows, this integration becomes essential. The configurator acts as a digital bridge between intent and execution, supporting lean manufacturing practices and scalable operations across bus production lines.

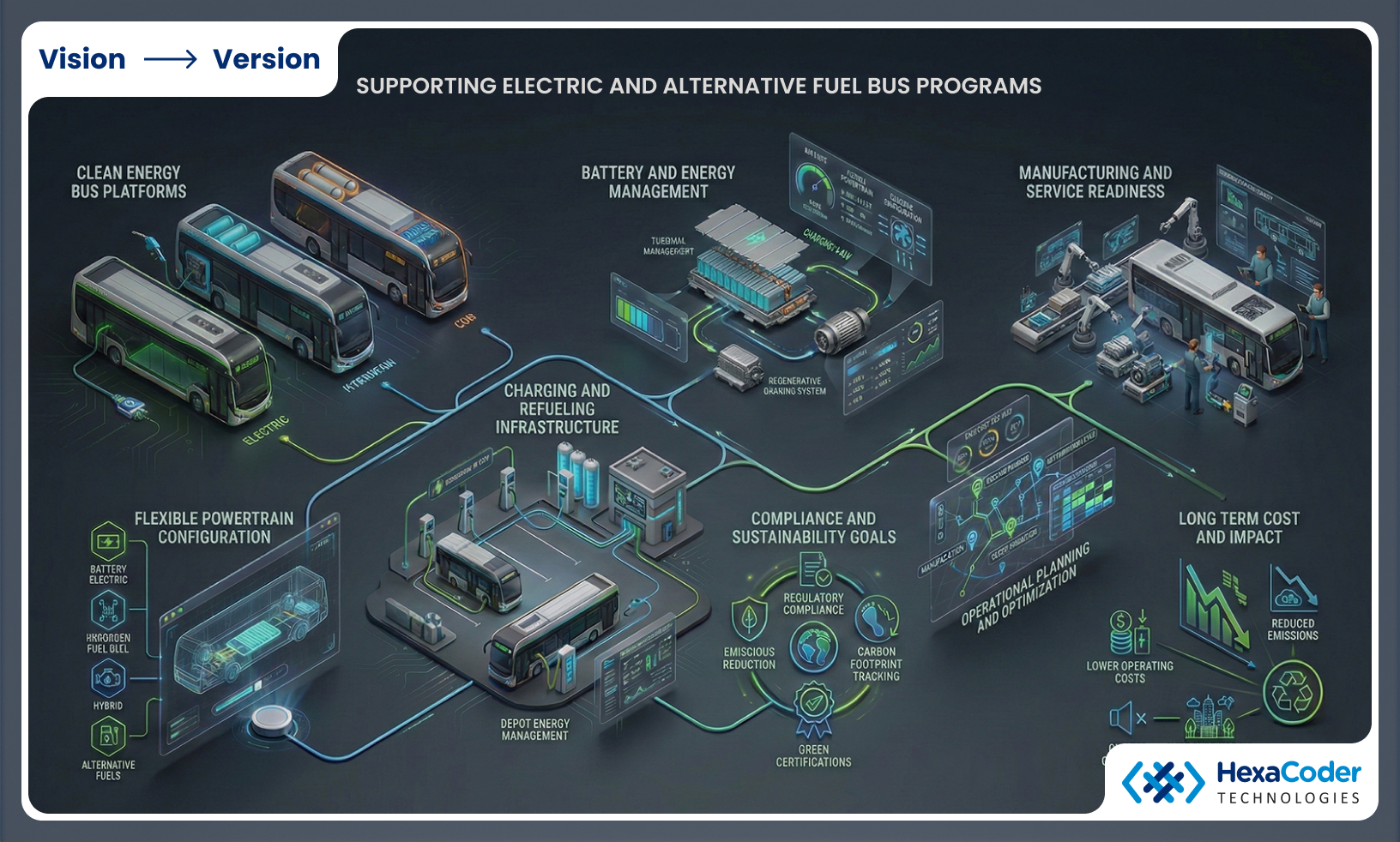

Supporting Electric and Alternative Fuel Bus Programs

The transition toward electric, hydrogen, and hybrid buses has added a new layer of complexity to bus manufacturing. Battery capacity, charging interfaces, thermal management, power electronics, axle loads, and regulatory compliance introduce interdependent configuration variables that are difficult to manage manually.

3D configurators are particularly valuable in this environment. They allow manufacturers to encode complex rule sets that account for energy systems, vehicle performance limits, safety standards, and regional regulations. As customers explore options, the configurator ensures that selections remain technically feasible and compliant.

For operators, this creates transparency. Trade-offs between range, seating capacity, charging time, and cost can be visualized and understood clearly. Instead of abstract specifications, stakeholders see the real impact of configuration choices.

For manufacturers, configurators reduce risk during early-stage adoption of alternative fuel technologies. New components and systems can be introduced gradually within controlled configuration boundaries, avoiding operational disruption. Engineering changes are validated digitally before reaching the factory.

As electric and hydrogen programs scale globally, configurators help standardize platforms while allowing regional flexibility. This balance is critical for manufacturers operating across diverse infrastructure environments and regulatory landscapes. Configurators become a stabilizing force during a period of rapid technological transition.

Reducing Returns, Rework, and Post-Delivery Issues

Post-delivery corrections are among the most costly issues in bus manufacturing. Misunderstood specifications, incorrect interior layouts, or missing features often originate from unclear communication during the configuration phase. These issues lead to rework, warranty claims, delivery delays, and reputational damage.

3D configurators significantly reduce this risk by aligning all stakeholders around a single, validated source of truth. Customers, dealers, sales teams, engineers, and production planners all see the same configuration before manufacturing begins. What is visualized is exactly what will be built.

This shared clarity eliminates ambiguity. Interior arrangements, accessibility features, safety systems, and branding elements are confirmed early, reducing last-minute changes. Configuration rules ensure that no incompatible or incomplete specifications enter production.

For manufacturers, the impact is measurable. Rework cycles decrease, quality metrics improve, and warranty costs are reduced. Production schedules become more stable, and customer satisfaction increases.

In industries operating on tight margins and long delivery timelines, these improvements directly affect profitability. By preventing errors rather than correcting them after the fact, 3D configurators act as a preventive quality tool embedded within the manufacturing process.

Strengthening Dealer and Distribution Networks

Dealers and regional distributors are critical touchpoints in bus sales, particularly across geographically diverse markets. However, explaining complex configurations consistently across locations is a persistent challenge. Reliance on brochures, spreadsheets, or local interpretations often leads to misrepresentation.

3D configurators provide dealers with a standardized, manufacturer-controlled tool. They enable interactive demonstrations of layouts, features, and compliance options while ensuring that only valid configurations are presented. This reduces dependence on individual expertise and minimizes interpretation errors.

Dealers gain confidence in what they sell. They can respond faster to customer questions, configure compliant solutions accurately, and reduce back-and-forth with headquarters. For manufacturers, this consistency strengthens brand control across markets.

Configurators also reduce the need for physical demo units, which are costly to maintain and limited in scope. Digital experiences scale instantly and stay up to date as products evolve.

By empowering dealers with accurate, interactive tools, manufacturers improve sales effectiveness while retaining governance over product representation. Stronger dealer enablement leads to higher-quality sales outcomes and more predictable order pipelines.

Enabling Data-Driven Product and Portfolio Decisions

Every interaction with a 3D configurator generates valuable behavioral data. Manufacturers gain insight into which configurations are most requested, which features drive decisions, and how preferences differ across regions, customer types, and use cases.

This data transforms product planning from assumption-based to evidence-driven. Manufacturers can identify high-demand options early, optimize component inventories, and refine offerings based on real market behavior. Features that are rarely selected can be redesigned or phased out.

Over time, configurator analytics inform broader portfolio decisions. Platform investments, technology roadmaps, and regional strategies can be aligned with actual customer demand rather than delayed sales reports.

For manufacturers managing diverse product lines, this visibility is strategic. It supports smarter capital allocation, reduces waste, and improves responsiveness to market shifts.

Ultimately, the configurator evolves from a sales tool into a decision intelligence system—guiding long-term product strategy and strengthening competitive positioning in a rapidly changing mobility landscape.

Integrating into a Digital Manufacturing Ecosystem

Modern bus manufacturing is increasingly digital. 3D configurators integrate seamlessly into broader digital ecosystems that include ERP, PLM, CPQ, and digital twin systems.

This integration ensures continuity from configuration to production to lifecycle management. As manufacturers adopt Industry 4.0 practices, configurators act as a foundational layer that connects customer intent with operational execution. Rather than operating as standalone tools, they become embedded components of intelligent manufacturing systems.

Why HexaCoders' 3D Configurator Solutions Stand Out

HexaCoders approaches 3D configurators as industrial systems, not marketing add-ons. Solutions are designed around real manufacturing constraints, complex configuration logic, and enterprise integration requirements.

HexaCoders builds custom 3D configurators that align with each manufacturer's product architecture, production workflows, and digital infrastructure. Configurators integrate with ERP, MES, and PLM systems to ensure that every configuration is production-ready.

The focus is on measurable impact—reduced errors, faster order cycles, improved efficiency, and scalable customization. This makes HexaCoders a strategic technology partner for bus manufacturers navigating increasing complexity and market pressure.

Conclusion: 3D Configurators as a Competitive Necessity

3D configurators are no longer optional tools for bus manufacturers. They are becoming essential infrastructure for managing customization, improving accuracy, and scaling operations in a rapidly evolving mobility landscape. Manufacturers that adopt configurators gain more than better visualization. They gain control over complexity, alignment across teams, and the ability to adapt to future technologies with confidence.

As customer expectations rise and product complexity increases, 3D configurators will continue to shape how buses are designed, sold, and built. For manufacturers focused on long-term competitiveness, the question is no longer whether to adopt 3D configurators—but how effectively they are implemented.