The Digital Twin Advantage: Simulating the Future to Optimize Your Present

Most companies are still relying on gut, yesterday, and best-guess assumptions in making decisions. The smartest among them have done more. They run their businesses in two worlds at the same time—the physical and the virtual. The first one builds. The second one forecasts. And when the two come together, efficiency is a goal but also an inevitable fact.

That is where the digital twin is brought in—a virtual copy of your actual assets, systems, or processes, updated in real time with operational data. It does not just indicate what is taking place; it indicates the reasons why it is taking place and what is most likely to take place next.

In short, digital twins allow organizations to simulate tomorrow's results and streamline today's performance. Whether it is predicting equipment failure before it happens or redesigning processes in the moment, this technology is revolutionizing how forward-thinking companies make decisions that matter.

What are Digital Twins?

Digital twins are not bleeding-edge technology. They are the bridge between vision and action—turning uncertainty into certainty and operational chaos into management.

The concept has been around for years under different names, but the term "digital twin" found its way into boardrooms only some years ago.

Early engineering efforts used static models, spreadsheets, and educated guesswork. Computer-aided design arrived later, showing what something would look like, but lacking real-time operational reflection.

The revolution occurred when the machines began to talk back in the form of sensors and networked systems. Information began to flow back from physical assets to the digital realm in real time. Simulation was no longer a silent movie. It was now a living, breathing reflection of actual operations.

That is the magic of simulation technology today. It not only predicts. It learns, it adapts, and it replicates the rhythm of performance in real time.

A runaway turbine, an overheating conveyor belt, a stretched delivery route these are no longer surprises waiting to happen. They can be monitored, they can be measured, and they can be adjusted before damage is done.

What Makes a Digital Twin Different

A digital twin is not a simulation tool or a traditional dashboard. A digital twin is the dynamic copy of a physical system, a virtual mirror that moves, develops, and reacts as the real system does. While the traditional simulations power individual instances, a digital twin executes a series of possibilities in real-time, reacting to real-time input and displaying results in advance.

digital twin essentially consists of four simple elements:

- The physical asset that is the real machine, product, or process in the physical world

- The virtual twin that is its digital counterpart that replicates all the details and characteristics.

- The data bridge that delivers a continuous flow of data from sensors, controls, and operations.

- The analytics engine that combs through patterns, predicts threats, and suggests improvements.

These together cause a constant cycle between the virtual and real worlds. What happens in one has a direct impact on the other.

This is where a digital twin breaks from the typical simulation. Rather than running one at a time, it builds an adaptive system that's continuously changing in response to actual conditions. A digital twin never waits for something to go wrong. It picks up warning signs early, alarms where performance is drifting off, and suggests changes before losses mount.

Digital twin software also enables the leaders to visualize what does not tend to make itself apparent, such as embedded frictions, slippages, or misalignments quietly siphoning away efficiency. With such insidious issues laid bare, productivity takes care of itself without pressure and crisis management round the clock.

In summary, digital twins revolutionize organizational operations. They move decisions from being reactive to proactive and unify data islands into authoritative insight.

That revolution flipped the script. Decision-making isn't human memory or stale reports anymore. With real-time simulation driving real-time decision-making, organisations can now anticipate disruptions, cycle through alternatives, and drive operations with an unprecedented level of accuracy.

The future of simulation isn't making prettier models. It's about capturing the living motion of your company as it unfolds in real time.

Why Digital Twins Are Important for Process Optimisation

Every company desires leaner operations, faster outcomes, and fewer surprises. Yet inefficiency likes to operate behind the scenes, in the neglected maintenance, murky communications, and minor decisions that silently devour time and money. The digital twin flips that upside down-it brings unseen wastage to light and converts raw information into intelligent action.

Digital twins allow teams to visualize how every component of their business reacts to others. When the production line falters, energy usage spikes, or customers' demand changes, the digital twin notices. The digital twin models the system in action and allows executives to make changes to their process before things escalate.

Here's how digital twins optimize business efficiency in simple terms:

Digital twins optimize efficiency by:

- Predictive Maintenance And Cost Management

: Equipment failures are even anticipated ahead of time. Instead of waiting for failures, maintenance is planned at the most ideal moment, reducing downtime and saving resources.

- Intelligent Resource Allocation:The digital twin uncovers exactly where material, labor, and energy are being under or overused, and managers can redistribute them more effectively.

- Scheduling-optimized workflow design: Because it is powered by actual performance, processes can be rearranged to eliminate bottlenecks and make interdepartmental coordination easier.

- Rapid Decision-Making: More complicated issues are simpler to comprehend whenever all of the variables are on the table simultaneously. Decision-makers can be sufficiently assured to make discerning and decisive decisions.

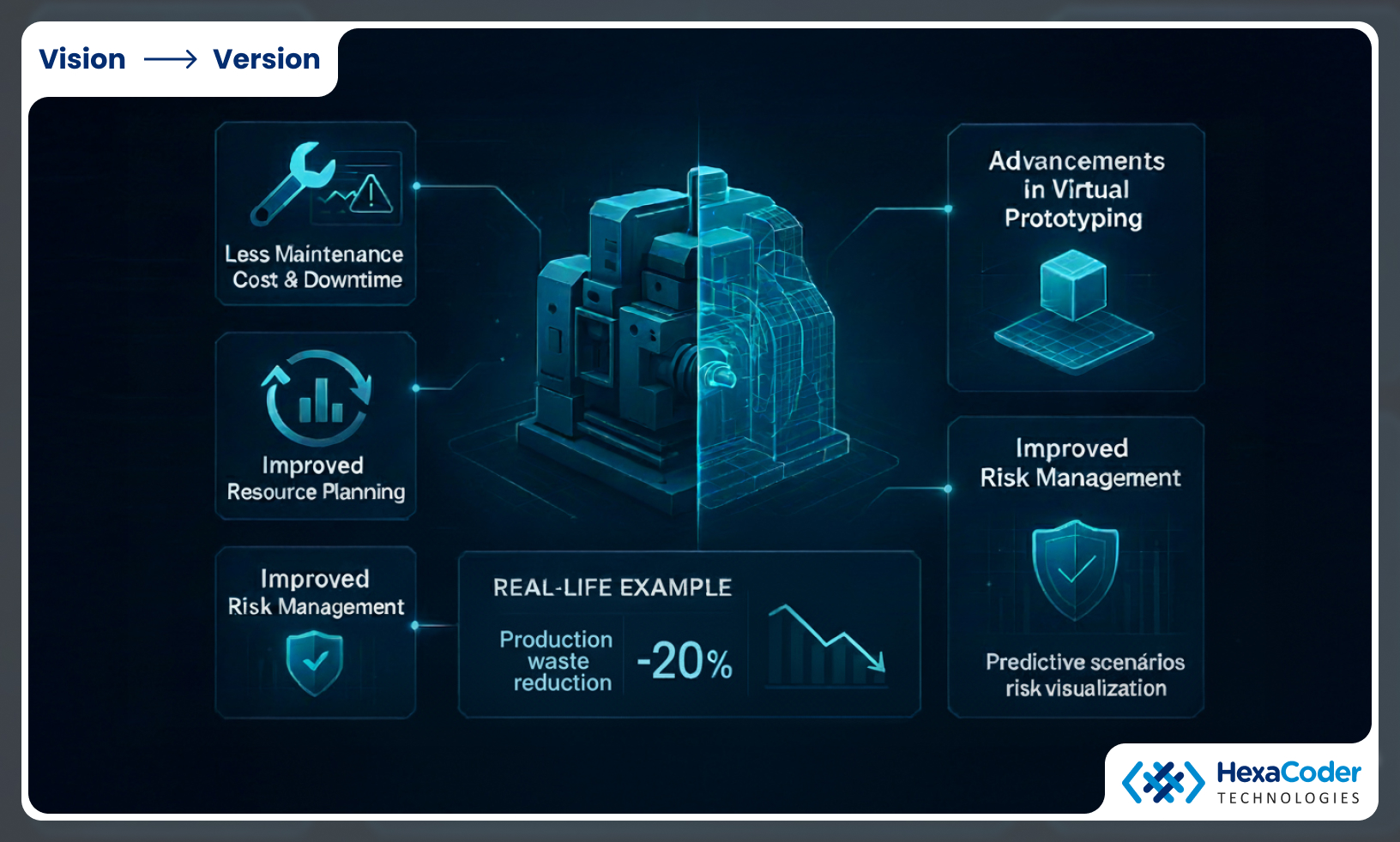

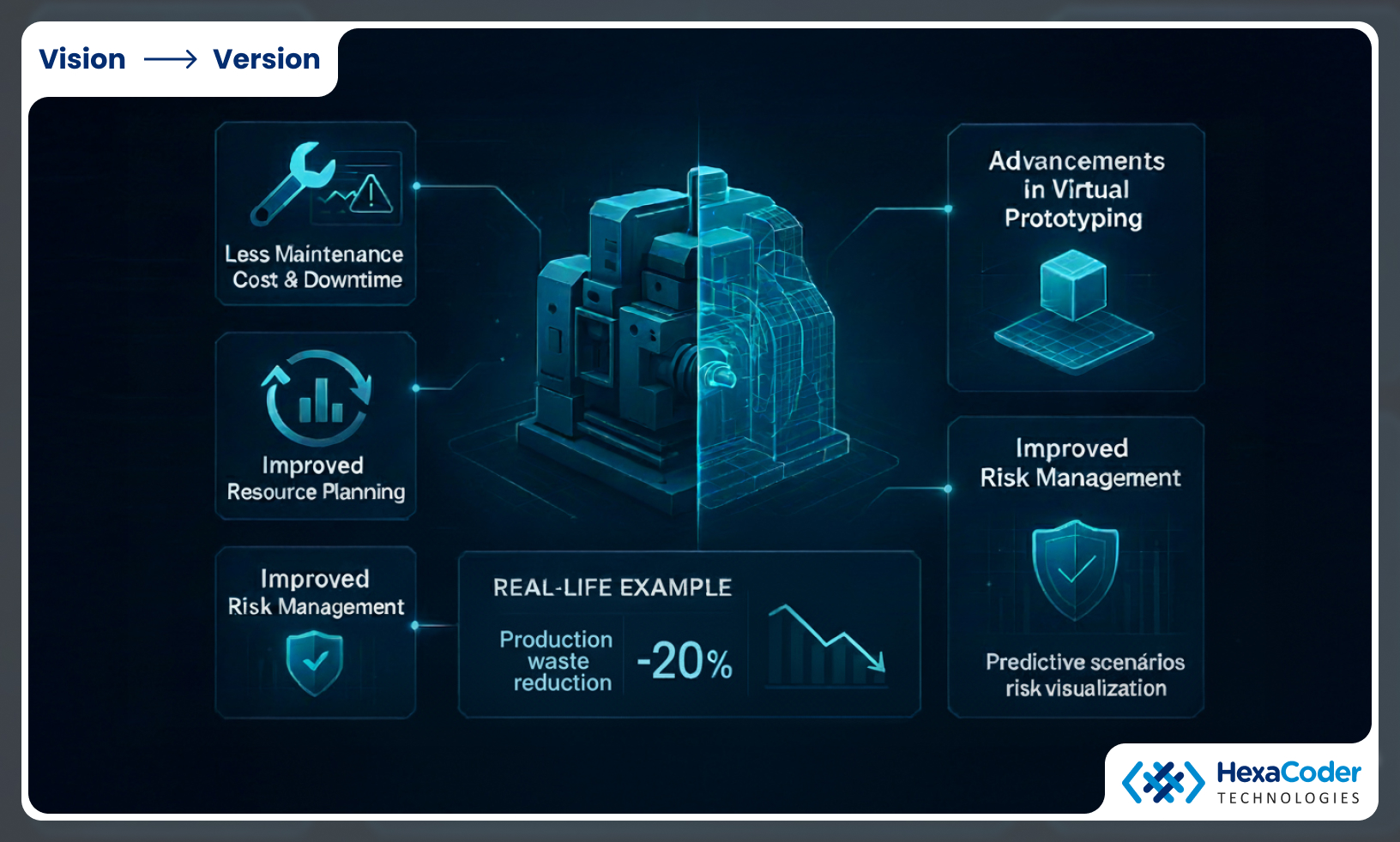

A production company modeled hundreds of combinations of workflows using a digital twin before optimizing their floor plan. The result was a twenty percent reduction in production waste and continuously improving performance.

This is the result of the application of simulation technology. This technology allows firms to model, test and optimize before any changes are made to a physical space. It is the difference between having a planning vision and a management plan that translates into measurable outcomes.

This is the difference between deterioration and improvement.

Inside the Engine: How Simulation Technology Powers It All

Every digital twin is underpinned by a cyclic process of data and analysis that keeps the digital twin updated. It is not a static model on a screen. It is a real-time simulation that reflects what the system is doing in the real world.

This all begins with the collection of data. Sensors, monitoring systems and controllers collect real-time data streams from machines, factory floors and the surrounding environment. All digital twin outputs are based on data inputs that track movements, detect pressures and measure temperature changes.

Secondly. we have modeling and testing. The virtual world uses this data to simulate real-world behaviors with precision. Then managers and engineers can experiment with different strategies and mode changes and see how every decision affects performance. It's like they have a practice arena, and the mistakes are free.

The third step is optimization. Once the system identifies where energy, time, or effort is being wasted, the twin suggests solutions. Solutions are experimented with in the virtual environment before being implemented in actual operation, creating a nicely balanced equilibrium between observation and reaction.

And eventually, there is continuous learning, which optimizes the process. The twin gets more and more accurate and reactive to the data it receives. It starts to recognize patterns, predict results, and suggest better approaches.

This exercise makes change a natural upgrade from a disruptive phenomenon. Decision-making is simple because it's informed and not speculated. Maintenance is pre-emptive, and efficiency is a default characteristic on a daily basis and not a target in the distant future.

Simulation technology gives organizations a clear picture of the nature of work. It converts raw information into knowledge and knowledge into quantifiable progress.

The Quantifiable Benefits of Digital Twin Simulation

Digital twins are not abstract ideas. They deliver concrete results that make processes more efficient, cost less, and performance more streamlined right away. With virtual replicas of systems, organizations can identify faults, streamline procedures, and make data-driven decisions.

The most significant benefits are as follows:

-

Less maintenance cost and downtime

Digital twins allow teams to chart future equipment failure in advance. Planned maintenance takes the place of unplanned repair, surprise downtime does not occur, and costly shutdowns are prevented.

-

Improved Resource Planning

The system reveals where material, energy, and labor are being wasted or left unutilized. Managers can plan resources more effectively, minimize waste, and improve productivity with this knowledge.

-

Advancements of Virtual Prototyping

Organizational disruptions are avoided through Virtual Prototyping which Democracy of Disruption provides. Assumptive decision-making is eliminated and relative Innovation is fast tracked.

-

Improved Operating Efficiency

Real time solution provision eliminates bottlenecks, delays and inefficiencies. The end product is more predictable output, performance and less operational variability.

-

Improved Risk Management

Hybrid scenarios enable Organizations to better respond to surprises. Virtual rehearsal provides containment and reduced business risk exposure.

Real Life Example:

For instance, a digital twin of a production line in a production company was used to achieve virtual simulation and production optimization. The company achieved a 20% reduction in production waste, consistent production, improved maintenance planning, resource optimization, and operational enhancement that resulted in cost reduction.

Decision-making delays are a thing of the past as digital twins provide virtual operational pygmalion. Performance optimization and predictive outcome influence and quantification were made realities through digital twins.

Real-World Examples of Digital Twin Optimization

Digital twins are improving industries through optimized, more efficient, predictable, and profitable operational performance. The best testament of their capabilities are real life examples of optimization.

Manufacturing

A production firm employed a digital twin of its assembly line. The digital twin enabled simulations of various workflows and identification of bottlenecks for timeline realignment. The end result was the elimination of twenty percent of waste and more efficient and less disruptive manufacturing.

Energy and Utilities

An energy provider constructed a digital twin of an electricity grid. By predicting equipment behavior and load distribution, engineers were able to anticipate transformer stress and outages. This resulted in improved reliability and reduced emergency repair costs.

Healthcare

Digital twins were pivotal in a hospital's patient-centered care planning. Condition-specific digital representations assisted clinicians in anticipating complications, standardizing care plans to improve recovery outcomes.

Urban Planning

A city used a digital twin of its transport system to improve traffic flow. By predicting traffic patterns and adjusting infrastructure and planning to optimize patterns, travel times were reduced and public safety was improved.

These examples show the real life capabilities of the technology.

These types of applications demonstrate what digital twins are put to use for. They don't simply reflect reality. They enable informed decision-making, uncover hidden inefficiencies, and improve performance in a quantifiable way.

Companies using this approach are able to move more quickly, reduce risk, and succeed with certainty, rendering wild systems intelligible and manageable processes.

Implementing Digital Twin Software in Your Organization

Deploying a digital twin is about more than deploying software. It's a strategy that takes a definite plan, cooperation, and a disciplined approach to data and operations. Companies that are successful are so because they follow a deliberate, phased approach.

-

Identify High-value Areas

Start with the highest-impact areas of your business. Maybe it is a production line most likely to experience downtime, an energy system with the highest running cost, or a process that impacts customer satisfaction. Being able to start high-value discussions allows earlier success that is also measurable.

-

Select the Best Digital Twin Software

Choose a platform that best fits your existing systems and grows with your company. The tool must have the capability for real-time simulation, excellent visualization, and actionable insights for managers and teams.

-

Create Cross-functional Teams

Digital twins are most effective when operations, IT, and engineering collaborate side by side. Each of them is bringing necessary knowledge — performance knowledge, process knowledge, and technical implementation knowledge. In that way, the digital twin is precisely a mirror image of reality and the suggestions made by it are practicable.

-

Set Data Pipelines

Accurate and right data streams are the foundation of a digital twin. Control operation, sensor, and monitoring systems must provide real-time data and be accurate. The quality of the data dictates the quality of the insights.

-

Define Clear Objectives And Metrics

Prior to broadcasting with a digital twin, establish what you are attempting to achieve. Are you reducing downtime, saving costs, or becoming more efficient, or all the above? Establish key performance indicators to quantify improvement and demonstrate value.

-

Pilot, Learn, And Scale

Start with a pilot in a test environment. Pilot processes, verify twin's predictions, and tune processes before scaling to other areas of the company. Early learnings will make large-scale deployment easier and more straightforward.

-

Continuous Improvement

A digital twin is not a project. It develops with your business. Teams need to constantly check performance data, streamline procedures, and update the model to account for change in the physical world. This ongoing process of optimization keeps the twin up to date and world-class.

Implementation Success Checklist

- Determine areas of high value to optimize

- Select a compliant and scalable digital twin platform

- Organize cross-functional teams to work together

- Develop actual and timely sources of data

- Define brief goals and track key metrics

- Pilot the twin in a test environment

- Continuously refine, tune, and expand

The result of the steps is that companies transition from theory to real gains. Digital twins transform decision-making, problem-solving, and operations performance along the way.

The Challenges and the Way Forward

Digital twins are highly beneficial with some challenges for companies to address. Quality data that is continuously updated must be present. Multisystem integration may be required. There has to be suitable skills in personnel, and software, sensors, and training are initial expenses. Operation data security is also required.

In spite of such challenges, their benefits far outweigh them. The digital twins allow for faster decision-making, proactive reaction to disruption, and continuous improvement. They transform complexity into clarity and uncertainty into opportunity.

For business leaders, the message could not be more obvious: digital twins don't merely monitor systems. They give leaders the vision to foresee problems, streamline processes in real time, and make every decision count. Companies that release this potential move forward with certainty, outpace the competition, and transform complexity into a clear roadmap for growth.