Why Ports Are Adopting Digital Twin Technology

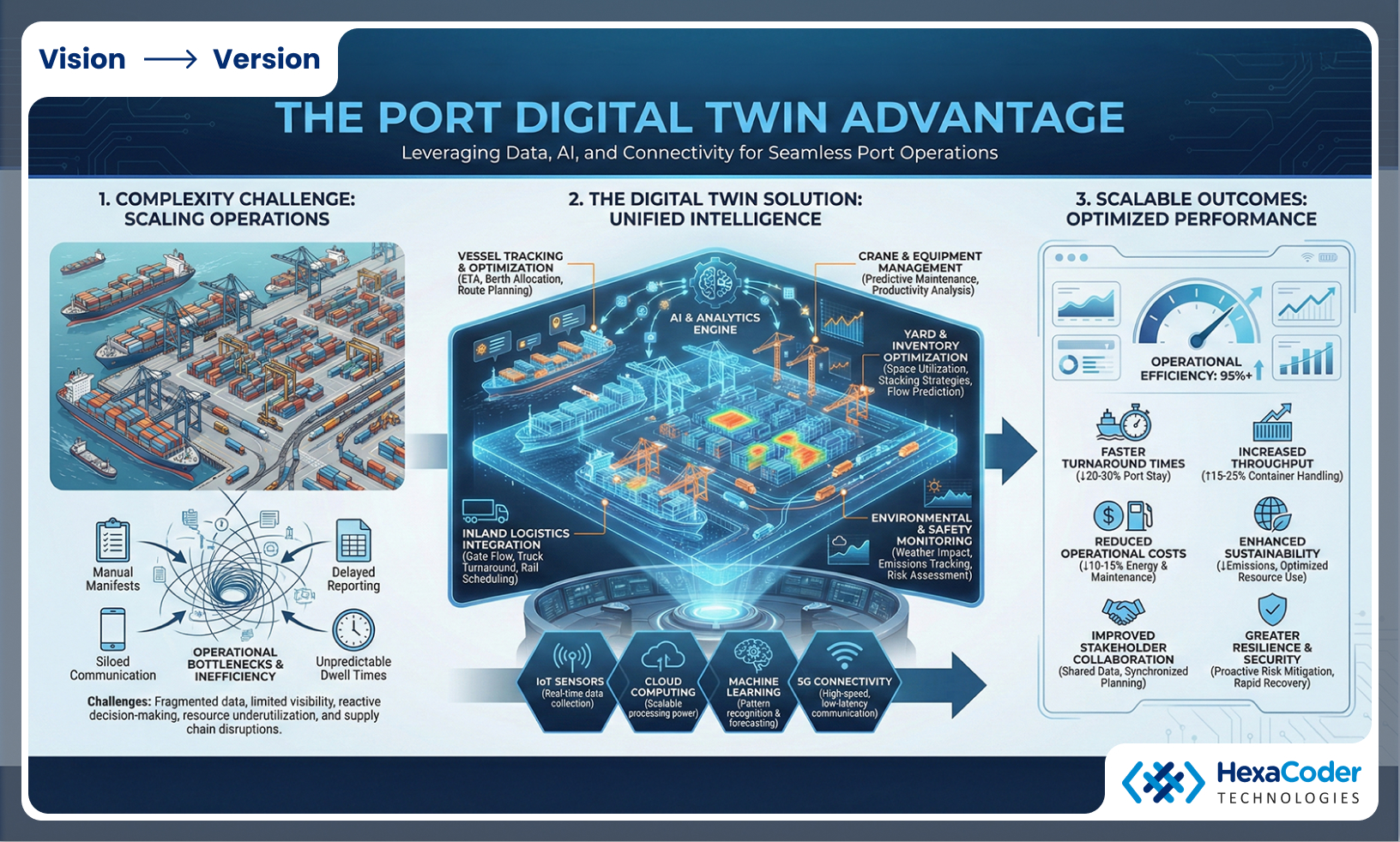

Global ports are under unprecedented pressure. Mounting cargo volumes, bigger vessels, stricter environmental regulations, and rising demand for transparency in operations are forcing port authorities to rethink their approach to infrastructure and logistics. Traditional port management systems that rely on fragmented data and delayed reporting can no longer accommodate this complexity. Hence, ports around the world are adopting digital twin technology as a strategic foundation for smarter, safer, and more efficient operations.

Digital Twins in Port Environments — A Perspective

A digital twin creates a live, data-driven virtual replica of physical assets, operations, and processes within a port. Unlike static models or dashboards, digital twins are constantly updated in real-time with data from sensors, IoT systems, terminal equipment, and operational platforms. This living digital environment allows port operators to observe performance, predict risk, simulate situations, and make much more accurate, timely decisions. Digital twins have thus become integral to modern port ecosystems, driven by automation and sustainability.

In ports, digital twins integrate live data from multiple sources such as quay cranes, yard equipment, vessel tracking systems, gate operations, weather services, energy networks, and terminal operating systems. This integration allows the digital twin to reflect real-world port conditions in near real time and model operational interdependencies — for example how a delayed arrival cascades through berth schedules, crane assignments, yard congestion, and landside operations.

Managing Operational Complexity at Scale

Modern ports operate at a scale where manual coordination or fragmented digital systems can no longer suffice. Digital twins provide a centralized view of berth occupancy, crane productivity, yard utilization, equipment status, truck queues, and vessel movements. Operators can simulate scenarios, reassign resources, and implement corrective actions before bottlenecks escalate — shifting operations from reactive firefighting to proactive orchestration.

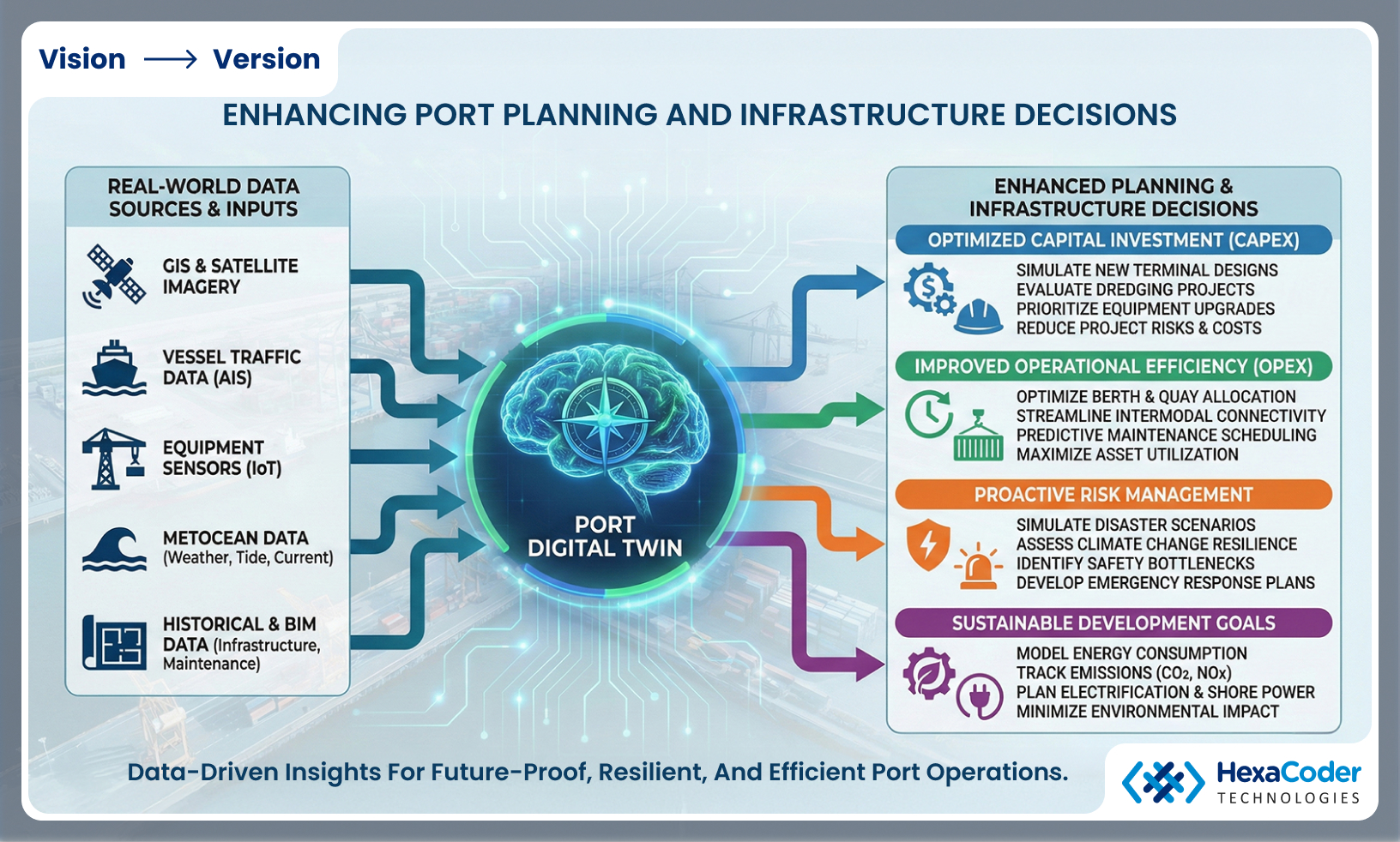

Enhancing Port Planning and Infrastructure Decisions

Infrastructure decisions such as berth expansions, yard redesigns, automation rollouts, or traffic-system updates are large capital commitments. Digital twins let planners test proposals in a virtual copy of the port, simulating traffic growth, equipment changes, and layout modifications to evaluate bottlenecks and trade-offs. This evidence-based approach reduces financial risk and enables phased investments aligned with actual demand patterns.

Enhancing Vessel Traffic and Berth Management

By integrating AIS feeds, weather forecasts, tide and draft constraints, berth availability, and terminal inputs, digital twins provide a continuously updated picture of vessel movements. Ports can simulate berth-allocation scenarios and implement the least disruptive plan, improving berth utilization, reducing idle time, and lowering anchorage congestion.

Safety Enhancement and Risk Management

Ports host heavy machinery, hazardous cargo, and dense vehicle flows. Digital twins consolidate sensor data, incident history, and environmental feeds to identify emerging risk patterns and simulate emergency responses (failures, spills, fire, evacuation). This enables preventive measures and validated response plans without exposing personnel or assets to danger.

Sustainability and Environmental Performance

Digital twins expose energy use, emissions, and resource consumption across port operations. Operators can test emissions-reduction tactics, optimize crane behavior and idling, and balance energy loads before committing changes — supporting green-port initiatives and regulatory compliance.

Enabling Predictive Maintenance and Asset Optimization

Continuous analysis of asset performance data allows condition-based maintenance, reducing unplanned failures, lowering downtime, and extending asset life. Ports can transition from scheduled maintenance to predictive strategies, cutting costs and increasing resilience.

Strengthening Decision-Making Across Stakeholders

Digital twins create a shared intelligence layer for terminal operators, port authorities, logistics partners, and regulators. Working on the same data-driven model reduces misalignment, speeds execution, and supports coordinated responses across the port ecosystem.

Why Digital Twins Have Become a Strategic Necessity

With rising complexity and volatility in global trade, digital twins move ports from reactive problem-solving to proactive optimization. They enable better planning, safer operations, improved sustainability, and increased coordination — making them core strategic infrastructure for future-ready ports.

How HexaCoders Lend Support

HexaCoders customizes digital twin solutions aligned to each port’s operational structure and strategic objectives. We integrate real-time operational data, simulation models, and visualization that link with existing systems including TOS, AIS, ERP, and asset management platforms — enabling planning, monitoring, and optimization at scale.

If you’re ready to adopt digital twin technology for your port, HexaCoders can help design, integrate, and scale a solution that improves visibility, safety, and operational performance.